Road pavement pre-assembling construction structure and construction method thereof

A road surface, pre-installed technology, applied in the field of civil engineering, can solve problems such as hidden dangers of road driving safety, and achieve the effect of ensuring safe passage, convenient operation, and reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

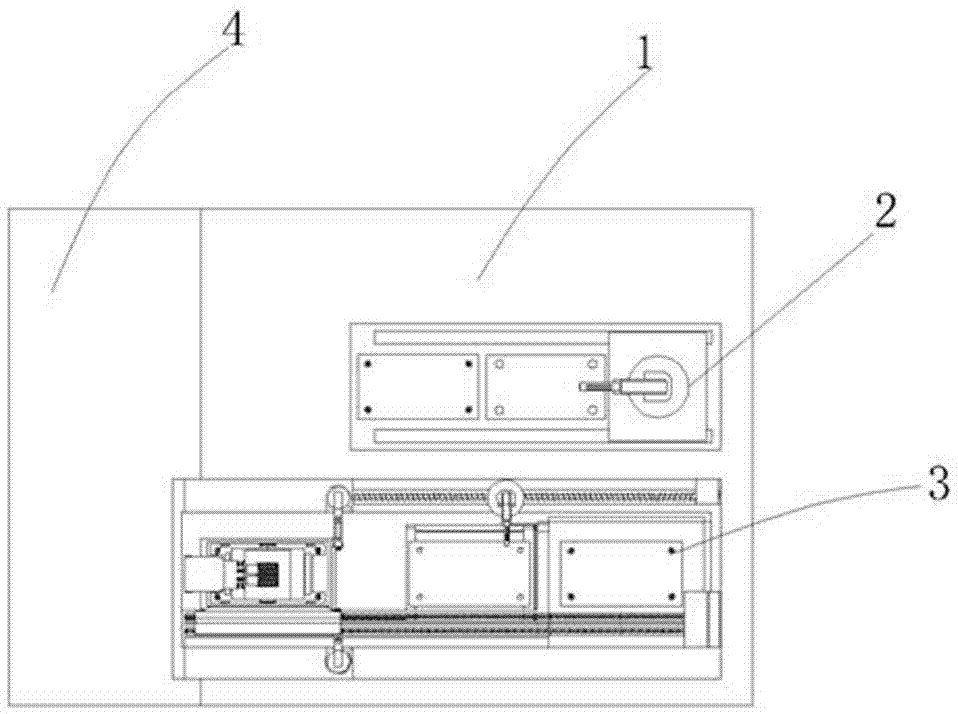

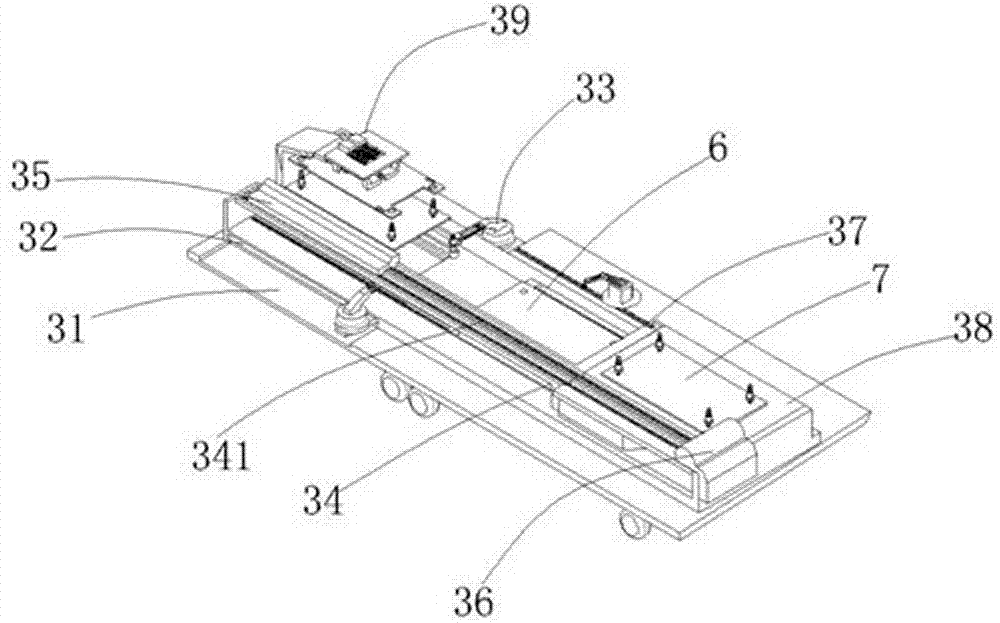

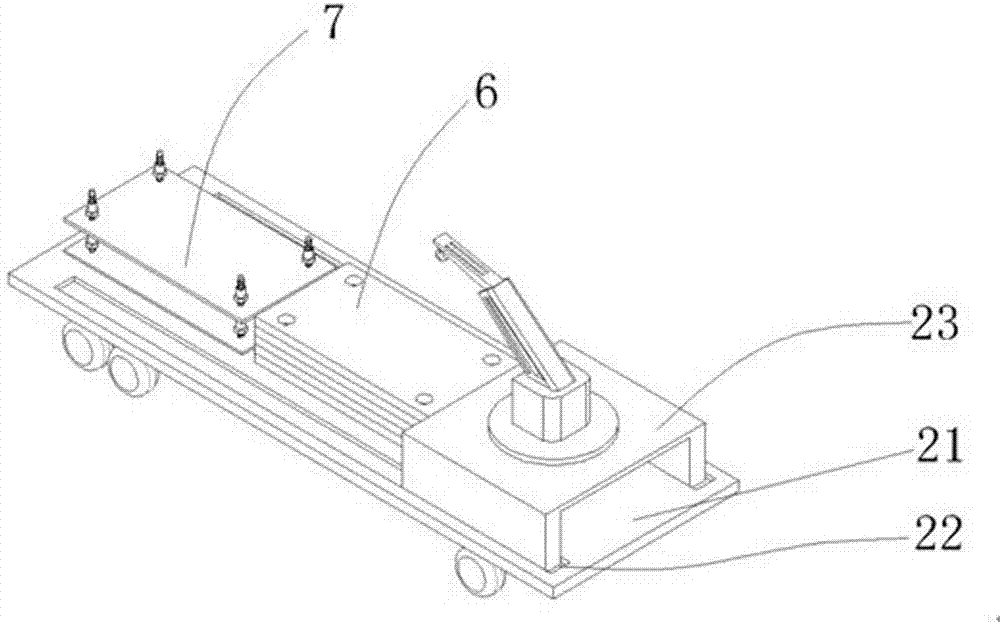

[0029] Road pavement pre-installed construction structure, including pre-installed conveying device 2 and picking up pre-installed device 3, said pre-installed conveying device 2 includes a base plate-21, said base plate-21 is provided with a chute-22, said chute-1 22 is installed with a sliding support platform 23 that slides back and forth on the chute one 22. The sliding support platform 23 is provided with a crane one. The cement board 6 and the horizontal adjustment plate 7 to be preinstalled are also stored on the bottom plate 21. The effect of crane one is to move and place the cement board 6 to be preloaded and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com