Shaft seal steam supply system used for ultra supercritical unit and provided with electric heater

A technology of ultra-supercritical units and electric heaters, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem of not being able to meet the high-temperature steam supply requirements of the front shaft seal of the high-pressure cylinder and the front shaft seal of the medium-pressure cylinder, and cannot be independent Problems such as temperature matching, shaft seal steam delivery temperature and rotor temperature do not match, etc., to achieve the effect of facilitating the layout of the power plant, increasing safety and failure resistance, and avoiding excessive thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

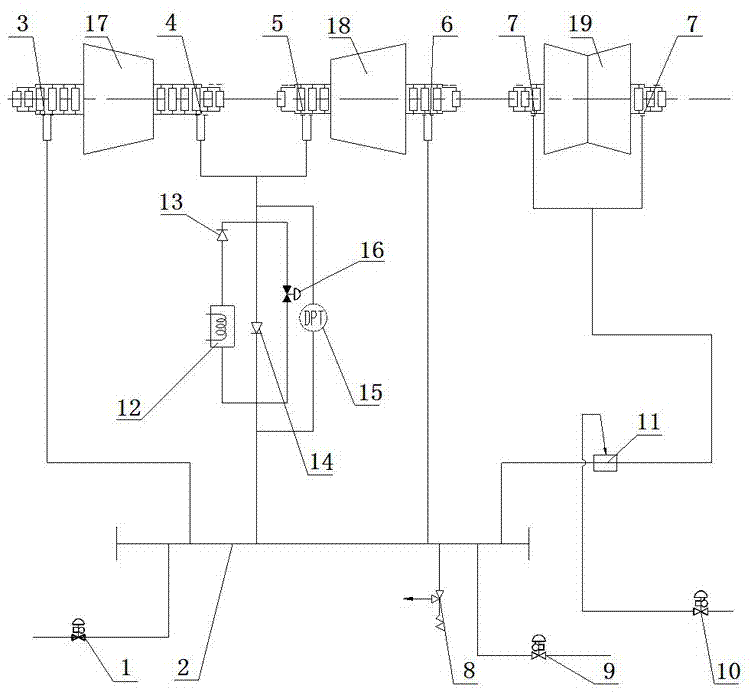

[0016] like figure 1 As shown, a shaft seal steam supply system with an electric heater for an ultra-supercritical unit surrounds a high-pressure cylinder 17, a medium-pressure cylinder 18, and a low-pressure cylinder 19, and includes an auxiliary steam regulating valve 1, a shaft seal main pipe 2, and a rear high-pressure cylinder Shaft seal 3, medium pressure cylinder rear shaft seal 6, high pressure cylinder front shaft seal 4, medium pressure cylinder front shaft seal 5, low pressure cylinder shaft seal 7, water spray desuperheater 11, electric heating device module and connecting pipes, the The inlet of the shaft seal main pipe 2 is connected to the auxiliary steam station through the auxiliary steam regulating valve 1; the outlet of the shaft seal main pipe 2 is directly connected to the rear shaft seal 3 of the high-pressure cylinder and the rear shaft seal 6 of the medium-pressure cylinder; the front shaft of the high-pressure cylinder The seal 4 and the front shaft se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com