Power supply used for oil type capacitor based sensor

A sensor and capacitor technology, applied in the field of power supply for sensors based on oil-type capacitors, can solve the problems of high-frequency noise interference, regular maintenance or replacement, unfavorable long-term use, etc., achieve long cycle life, meet power consumption, Fast charging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

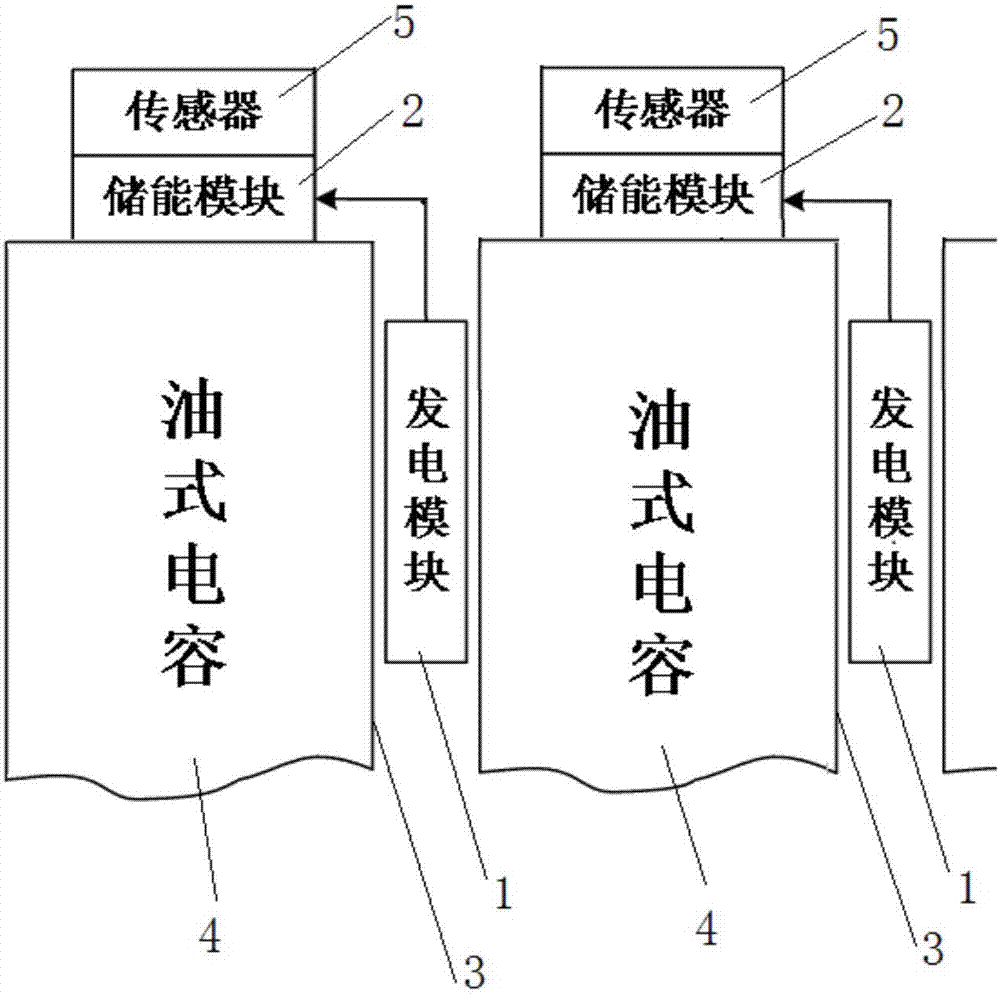

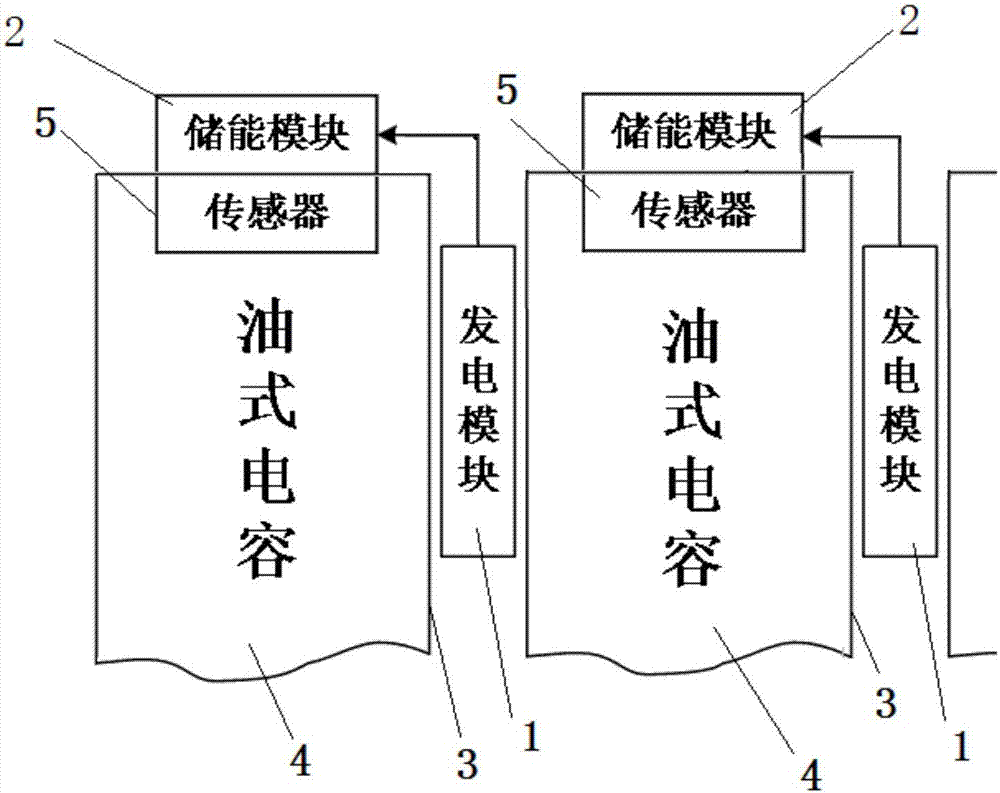

[0023] See figure 1 As shown, it is a schematic diagram of the structure of the power supply for sensors based on oil-type capacitors of the present invention figure 1 .

[0024] Such as figure 1 As shown, an oil-type capacitor-based sensor power supply includes a power generation module 1, an energy storage module 2 and a number of oil-type capacitor shells 3. The power generation module 1 and the energy storage module 2 are connected by wires, and the power generation The module 1 is arranged between the two oil-type capacitor shells 3. The oil-type capacitor shell 3 undergoes natural deformation during the operation of the oil-type capacitor 4, and the power generation module 1 generates a certain amount of Electric energy, the energy storage module 2 converts and stores the electric energy for use by the sensor 5 located near the sensor power supply.

[0025] Wherein, the oil-type capacitor 4 itself has a large volume, and the oil-type capacitor housing 3 undergoes a large amou...

Embodiment 2

[0029] According to the above-mentioned power supply for sensors based on oil capacitors, this embodiment differs from it in that the energy storage module 2 is composed of a number of super capacitors. The super capacitors are used as energy storage media and their charge and discharge cycles are The service life is more than 100,000 times, the charge retention ability is strong, the leakage power is small, and the charging is fast.

Embodiment 3

[0031] The difference between this embodiment and the above-mentioned power supply for sensors based on oil-type capacitors is that the calculation formula for the hourly power consumption of the sensor 5 is:

[0032] Q 1 =I×t×n 3

[0033] Among them, Q 1 Is the power consumption of the sensor 5 per hour, I is the current value used for the continuous working of the sensor 5 after starting, t is the time of the continuous working, n 3 Is the number of starts of the sensor 5 per hour;

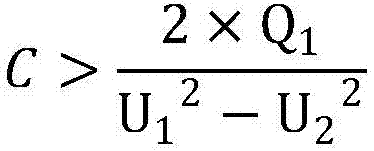

[0034] Therefore, the hourly energy storage capacity of the energy storage module 2 satisfies the following calculation formula:

[0035]

[0036] Where C is the energy storage capacity of the energy storage module 2 per hour, and Q 1 Is the power consumption of the sensor 5 per hour, U 1 Is the full voltage value of the energy storage module 2, U 2 Is the discharge cut-off voltage value of the energy storage module 2;

[0037] The formula for calculating the electricity generated per hour by the power ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com