Roll brush and dust remover thereof

A technology for a vacuum cleaner and brush bristles is applied in the field of vacuum cleaners with the roller brush, which can solve the problems that the extension length of the brush bristles cannot be adjusted, and cannot be applied to the needs of ground cleaning work under different conditions, and achieves the effect of a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

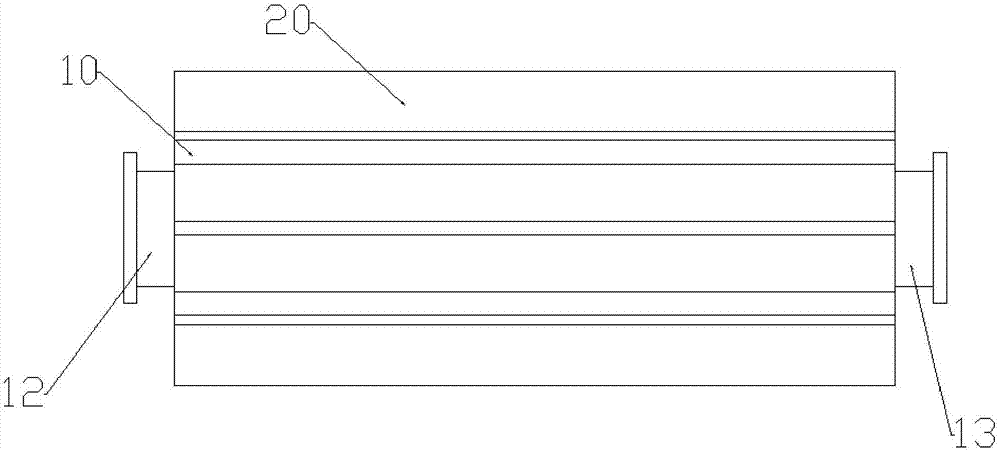

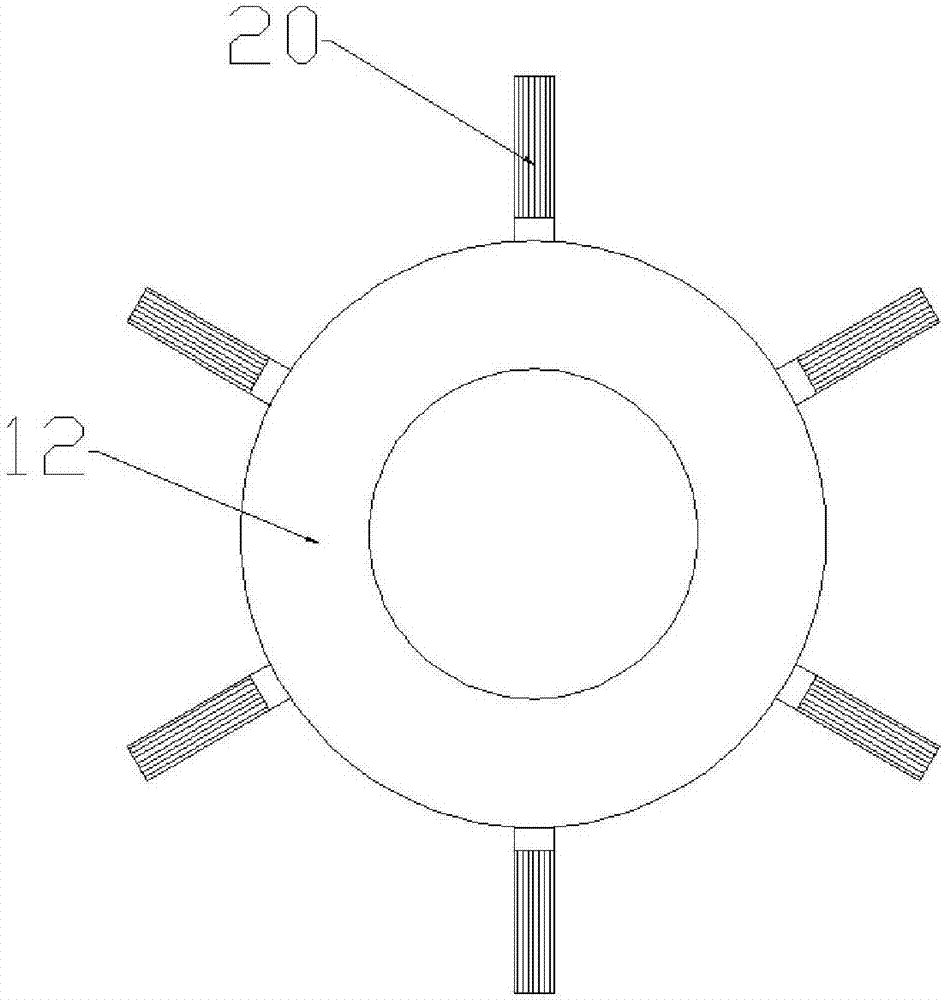

[0065] like Figure 1-2 As shown, a roller brush provided in this embodiment includes: a roller body 10 and a plurality of bristle strips 20;

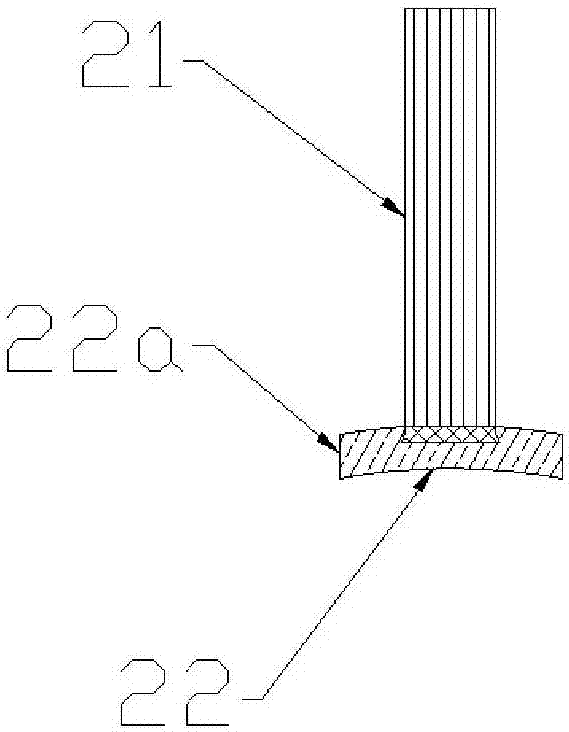

[0066] like image 3 As shown, the bristle bar 20 includes: a base 22 and bristles 21 arranged on the base 22;

[0067] like Figure 4 As shown, the outer circular side of the roller body 10 is provided with an assembly groove 11 along the axial direction;

[0068] like Figure 5-7 As shown, the base 22 of the bristle strip 20 is inserted into the assembly groove 11, and the bristles 21 on the bristle strip 20 protrude from the assembly groove 11;

[0069] In the radial direction of the roller body 10, the length of the bristles 21 of the bristle bar 20 protruding from the fitting groove 11 is adjustable.

[0070] The base 22 and the bristles 21 are arranged in a T shape, the base 22 and the bristles 21 are vertically arranged, and the left and right sides of the base 22 protrude from the bristles 21 to form a raised portion 22a f...

Embodiment 2

[0087] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0088] like Figure 8-11 As shown, the left and right sides of the base 22 are respectively provided with first engaging structures 22b;

[0089] The left and right side walls of the assembly groove 11 are respectively provided with a second engaging structure 11b;

[0090] The first engaging structure 22b cooperates with the second engaging structure 11b to engage the base 22 in the fitting groove 11 .

[0091] The number of the second engaging structures 11b is 3 groups, and the 3 groups of second engaging structures 11b are arranged at intervals in the radial direction of the roller body 10; Figure 12 and 13 As shown, the adjustment of the length of the bristles 21 protruding from the assembly groove 11 can be realized by adjusting the first snap-in structure 22b to snap-fit with different groups of second snap-in structures 11b;

[0092] In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com