Manufacturing method of metal mobile phone case and mobile phone case manufactured by the method

A technology of a mobile phone casing and a manufacturing method, which is applied in the directions of telephone structure, branch equipment, electrical components, etc., can solve problems such as high cost and mobile phone bending, and achieve the effects of reducing cost, improving yield, and reducing time-consuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

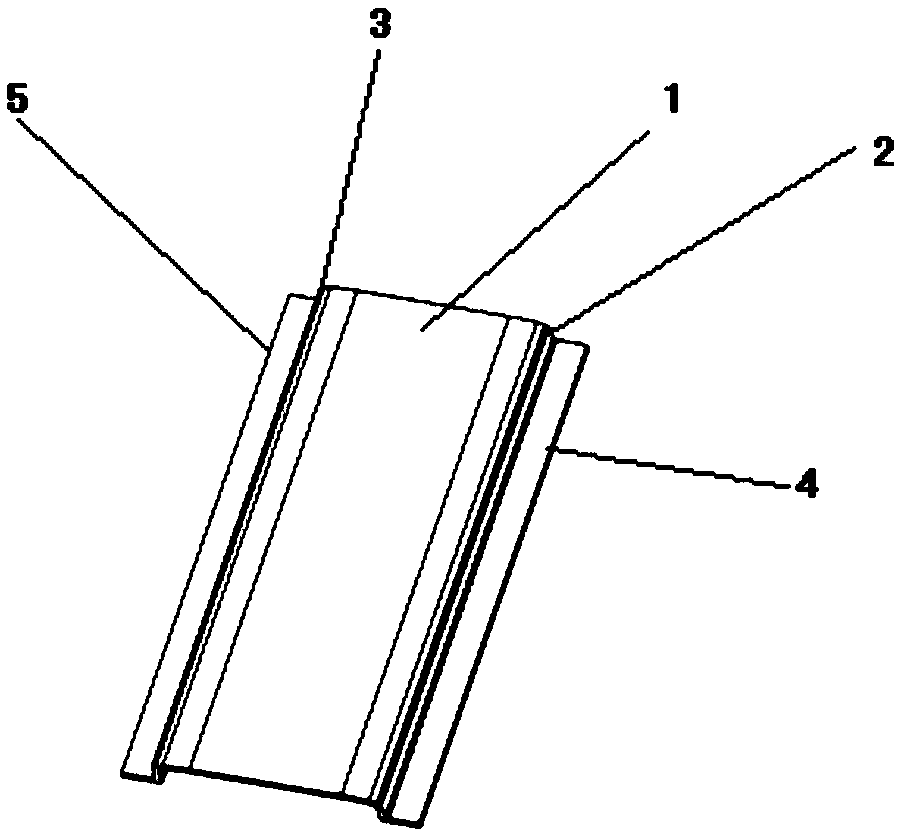

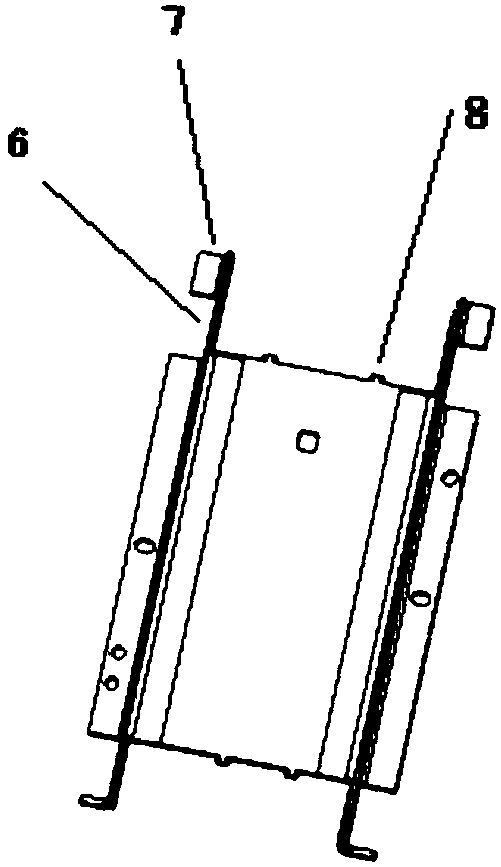

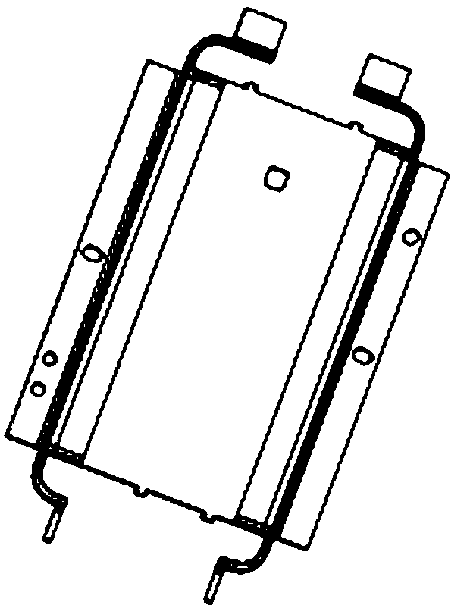

[0049] see Figure 8 , is a mobile phone casing manufactured by the method of the present invention, the mobile phone casing is composed of a raised casing blank in the middle, an upper fitting 12 and a lower fitting 9, and the raised middle section of the casing blank includes a horizontal top surface 1 and The left vertical surface 3 and the right vertical surface 2, the left vertical surface 3 is provided with a horizontal left extension section 5 outwards, and the right vertical surface 2 is provided with a horizontal right extension section 4 outwards, the upper and lower ends of the top, 1 A notch is respectively provided, and arc-shaped edges are respectively arranged on both sides of the notch, and an assembly segment 7 is arranged on the outer side of the proximal end of the arc-shaped edges on both sides, and a plurality of protrusions 8 are respectively arranged on the upper and lower edges of the top surface 1. In this embodiment, two protrusions 8 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com