Tester for detecting operation force in full-automatic assembly of large ship-shaped switch and production process thereof

A technology for assembly detection and operation force, which is applied in the field of automatic assembly inspection and operation force testing machines for large boat-shaped switches, can solve the problems of increasing the manufacturing cost of related production enterprises and poor uniformity of products manufactured by manual operation, and achieves the effect of high uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

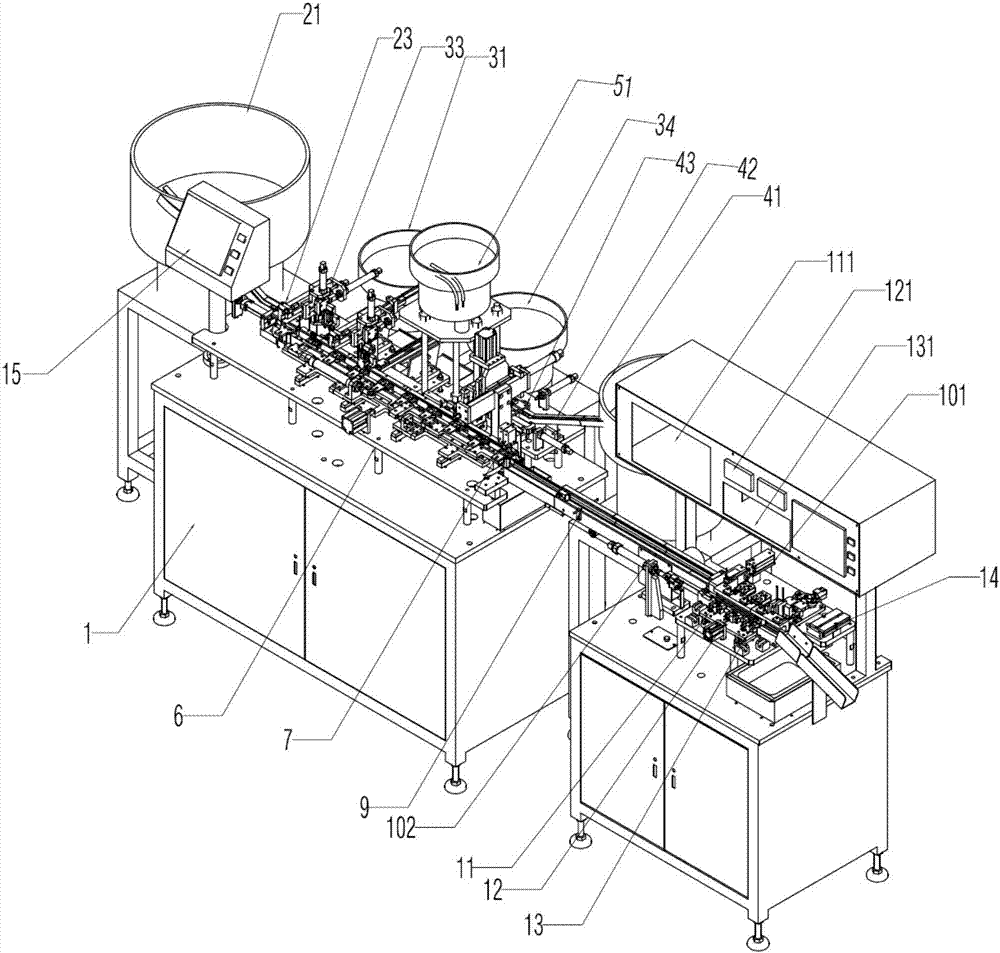

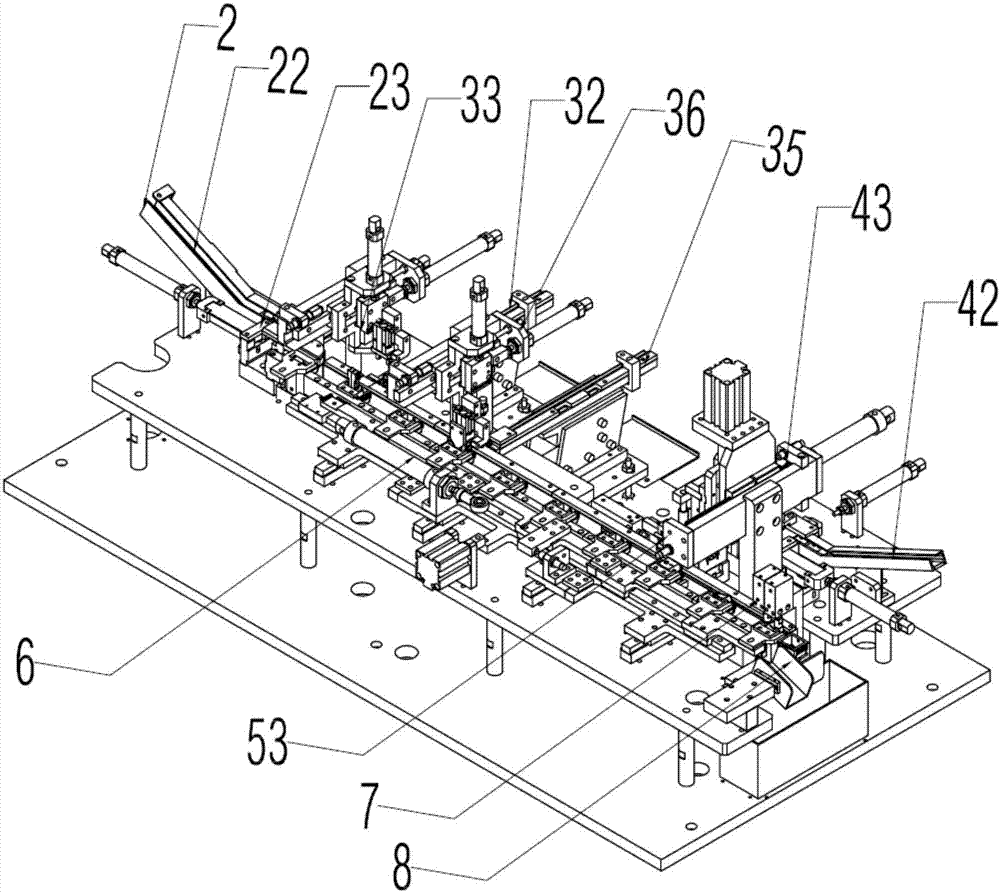

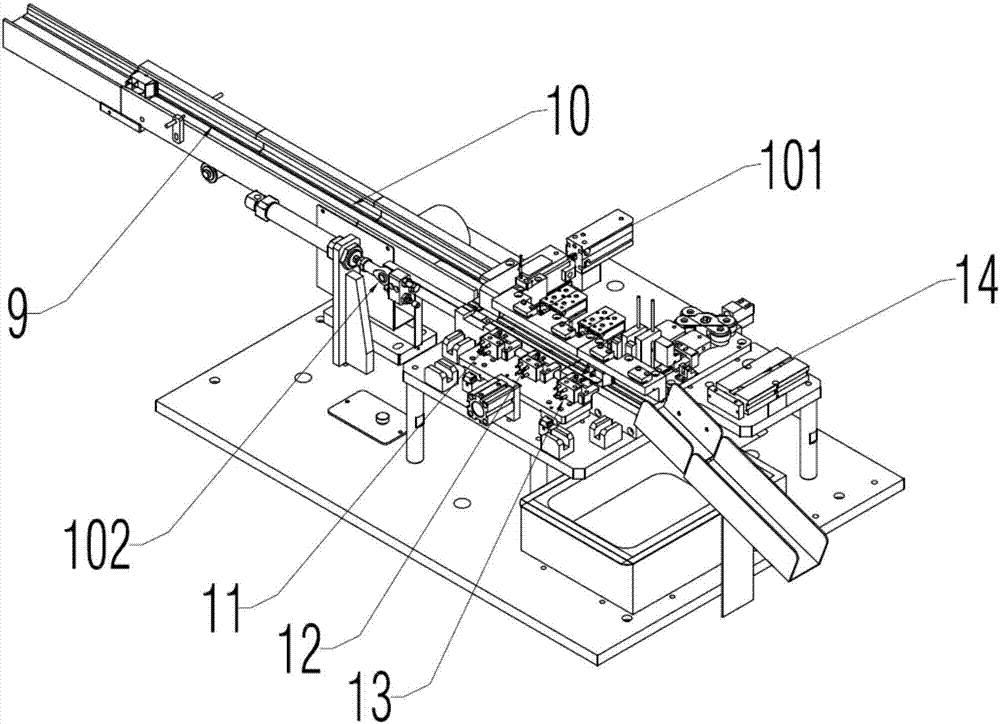

[0040] Such as Figure 1 to Figure 8 As shown, it is a fully automatic assembly detection operating force testing machine for a large boat-shaped switch in accordance with the present invention, which includes a frame 1, a casing detection and feeding device 2, a moving contact sheet feeding device 3, and a mask group detection and feeding device 4 , spring assembly device 5, material transfer device 6, conduction detection device 7, NG sorting device 8, conveying device 9, material transfer device 10, neon lamp detection device 11, resistance detection device 12, operating force detection device 13, NG Sorting device 14, control device 15.

[0041] The shell detection feeding device 2, the moving contact sheet feeding device 3, the mask group detection feeding device 4, the spring assembly device 5, the material shifting device 6, the conduction detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com