Novel cutting liquid cooling device for lower yoke plate drilling

A cooling device and cutting fluid technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of insufficient cooling of the cutting part of the drill bit, splashing cutting fluid, etc., to achieve good use effect and reduce resistance. , The effect of preventing splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

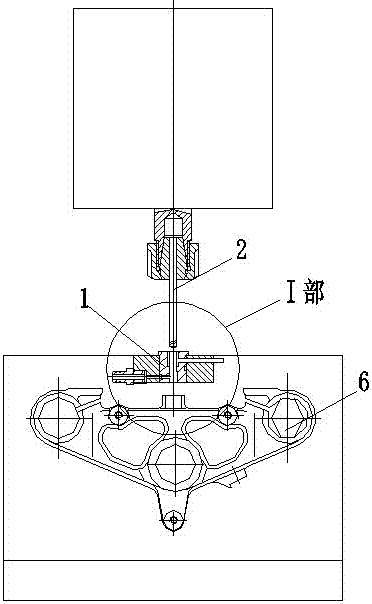

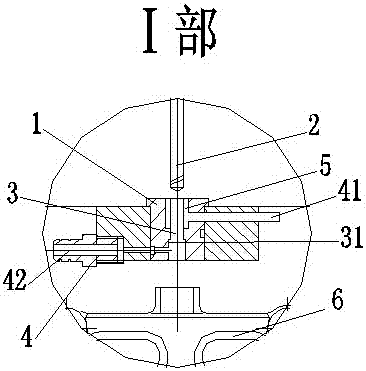

[0015] The present invention is arranged on the drill sleeve 1, and the drill sleeve 1 is provided with a drill hole 3 for the drill bit 2 to penetrate and protrude;

[0016] The drill sleeve 1 is also provided with a cutting fluid channel 4 , and the cutting fluid in the cutting fluid channel 4 cools the drill bit 2 penetrating into the drill hole 3 .

[0017] The drill sleeve 1 is provided with an interlayer 5 located outside the borehole 3 on the upper part of the borehole 3, an upper cutting fluid channel 41 communicates with the interlayer 5, and a lower cutting fluid channel 42 communicates with the drill hole 3. The lower part of hole 3 communicates.

[0018] The cutting fluid channel 4 is arranged obliquely downward.

[0019] A plurality of grooves 31 are circumferentially arranged at the lower part of the borehole 3 .

[0020] The working process of the present invention is: the drill bit 2 of the present invention enters the drill sleeve 1 when running downwards, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap