Winch steel wire rope tension control device

A technology of tension control and steel wire rope, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of affecting work efficiency, poor continuity of monitoring timeliness, and low reliability, and achieves a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

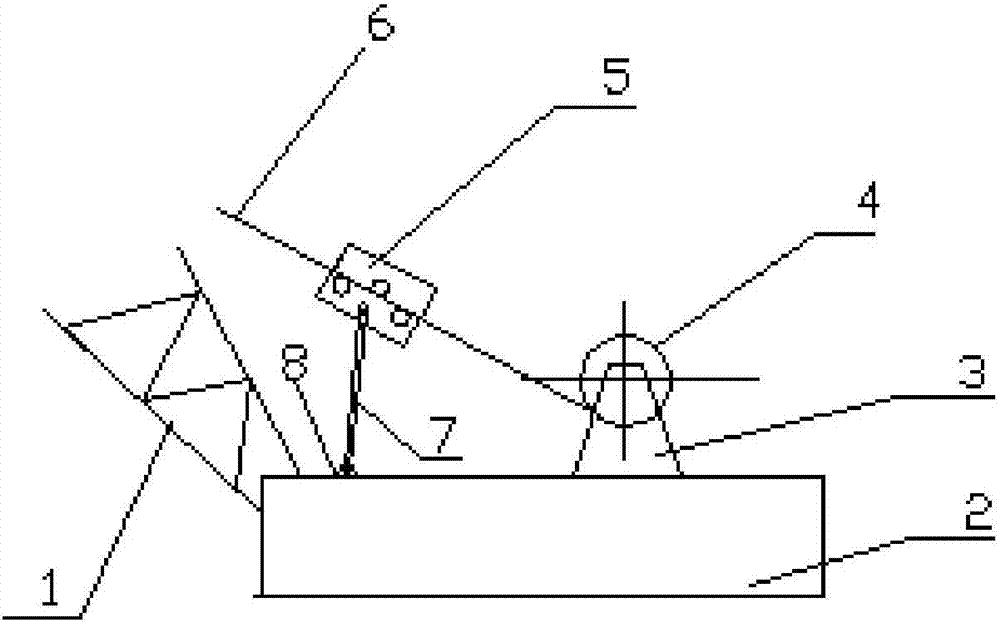

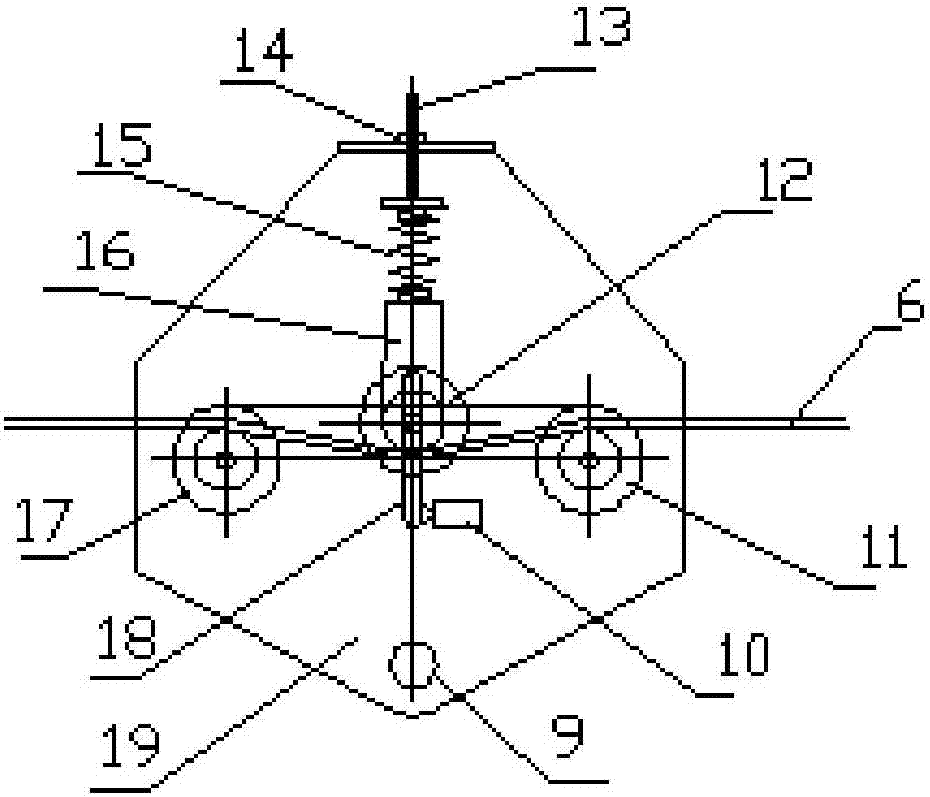

[0015] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-2 As shown, a hoisting steel wire rope tension control device includes a tie rod 7 installed on the machine platform 2 through a tie rod bracket 8 close to the direction of the hoist 4 rope on the machine platform, and the hoist 4 is fixed on the machine platform 2 through the The hoisting bracket 3 is arranged on the machine platform 2, the upper end of the tie rod 7 is provided with a three-pulley assembly 5, and the steel wire rope 6 is connected with the pulley at the upper end of the boom tail section 1 after passing through the three-pulley assembly 5, and is characterized in that: The three pulley assembly 5 includes two front and rear symmetrical installation side plates 19, and three pulleys are arranged between the installation side plates 19, wherein the left pulley 11 and the right pulley 17 are fixed sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com