Baffling element of pipe shell type heat exchanger and working method thereof

A shell-and-tube heat exchanger and element technology, which is applied in the field of baffle elements, can solve the problems of easy wear of bellows and baffle plates, difficult for fluid to reach turbulent flow, unstable tube-side structure, etc., so as to improve surface heat transfer. coefficient, resistance to dirt and vibration, the effect of simplifying the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

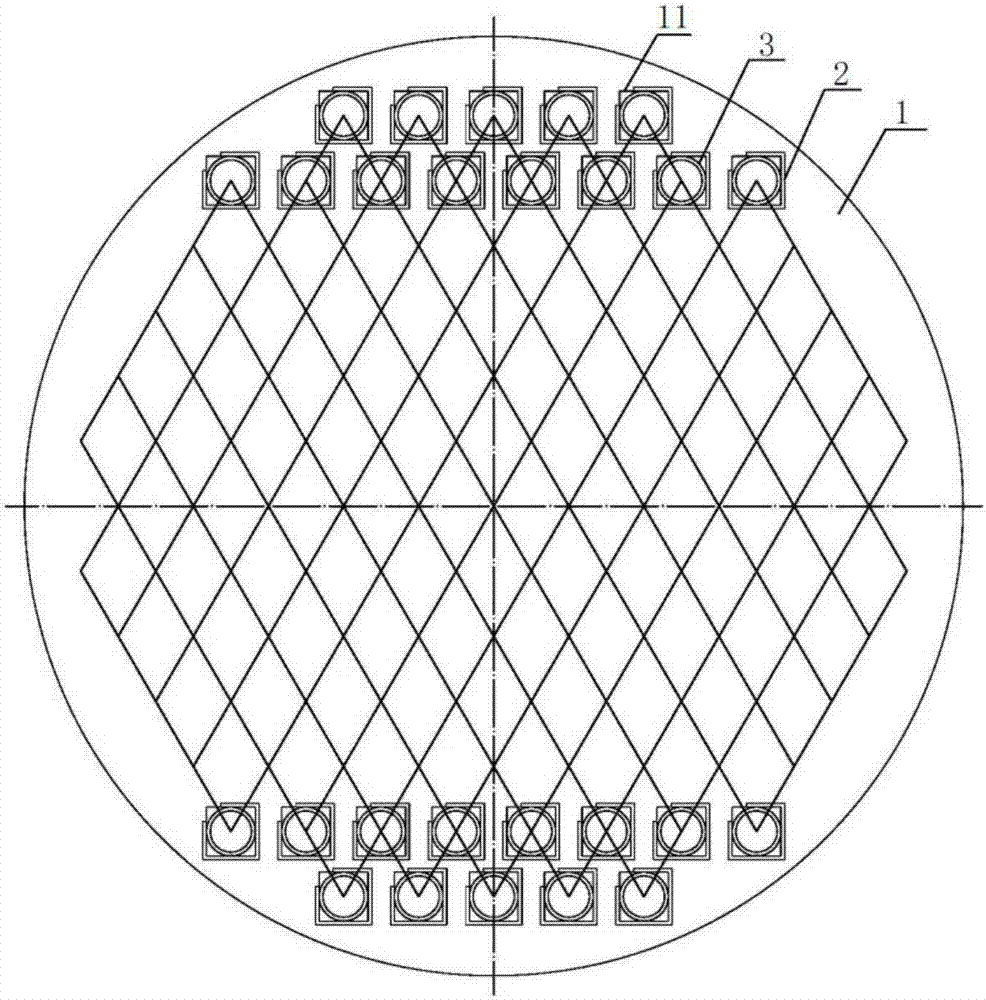

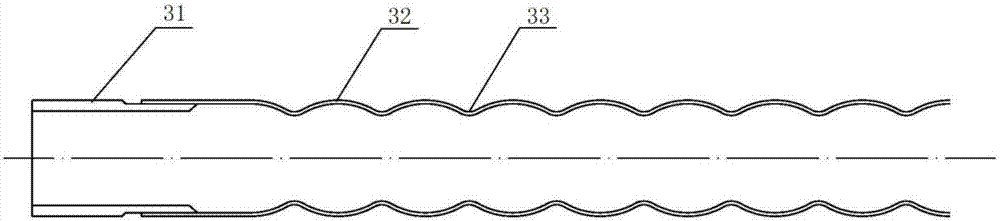

[0020] Such as figure 1 As shown, the baffle element of a shell-and-tube heat exchanger according to the present invention includes a square-hole baffle 1 and a casing fixing plate 2; In the housing, it is used to fix the bellows 3; the square hole baffle plate 1 is a circular orifice plate matching the inner diameter of the housing, and a plurality of square through holes 11 are evenly distributed on it; the sleeve fixing plate 2 is embedded in the square through hole In the hole 11 , the inner side is tangent to the crest section of the bellows 3 .

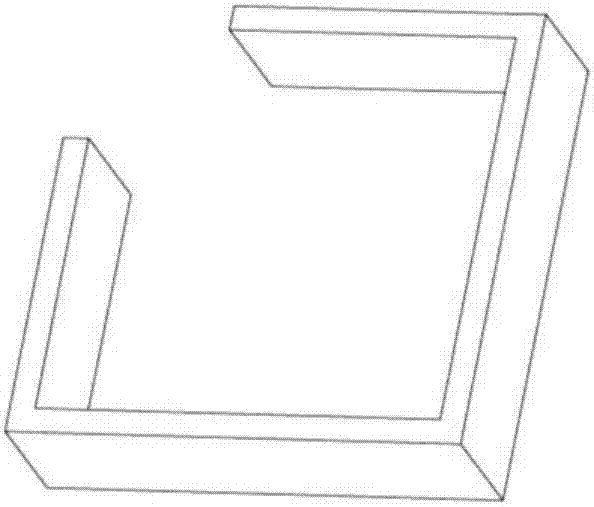

[0021] Such as image 3 As shown, the casing fixing plate 2 is a square frame structure matched with the square through hole 11, and one of the right angle sides of the square frame structure is cut off by 1 / 4 side length respectively.

[0022] The sleeve fixing plate 2 is embedded in the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com