Test method for evaluating freezing and thawing resistance of cement-based waterproof bonding layer

A technology of waterproof adhesive layer and test method, which is applied in the direction of testing material strength by applying stable shear force, testing material strength and strength characteristics by applying stable tension/pressure, and achieving obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A test method for evaluating the freeze-thaw resistance of a cement-based waterproof bonding layer, comprising the steps of:

[0047] 1) Moisten the prefabricated 300mm×300mm×50mm C40 cement concrete block with acrylic emulsion at a dosage of 200g / m 2 , stand at room temperature for 5 minutes;

[0048] 2) Smear cement-based material on the wet cement concrete block, scrape it with a cement scraper, and control the thickness at 4mm; proportional composition.

[0049] 3) Place the cement concrete blocks coated with cement-based materials at room temperature for 0.5h;

[0050] 4) Add AC-13 type asphalt mixture when the cement-based material is in the initial setting state;

[0051] 5) Curing the cement concrete composite specimens paved with asphalt mixture for 14 days at room temperature;

[0052] 6) Cut the well-cured cement concrete composite specimen into a shear specimen of 100mm×100mm×100mm, and a drawing specimen of pavement layer 50mm×50mm×50mm+cement concrete sl...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is only:

[0071] Step (7), put 20 shear test pieces and 20 pull test pieces into the rubber test box respectively, add drinking water to make it cover the top surface of the test pieces by 2mm, and then freeze in the -18°C refrigerator for 16h , within 10 minutes, put the specimen frozen for 16 hours into 25 ℃ water and melt for 24 hours for 1 cycle of freeze-thaw cycle.

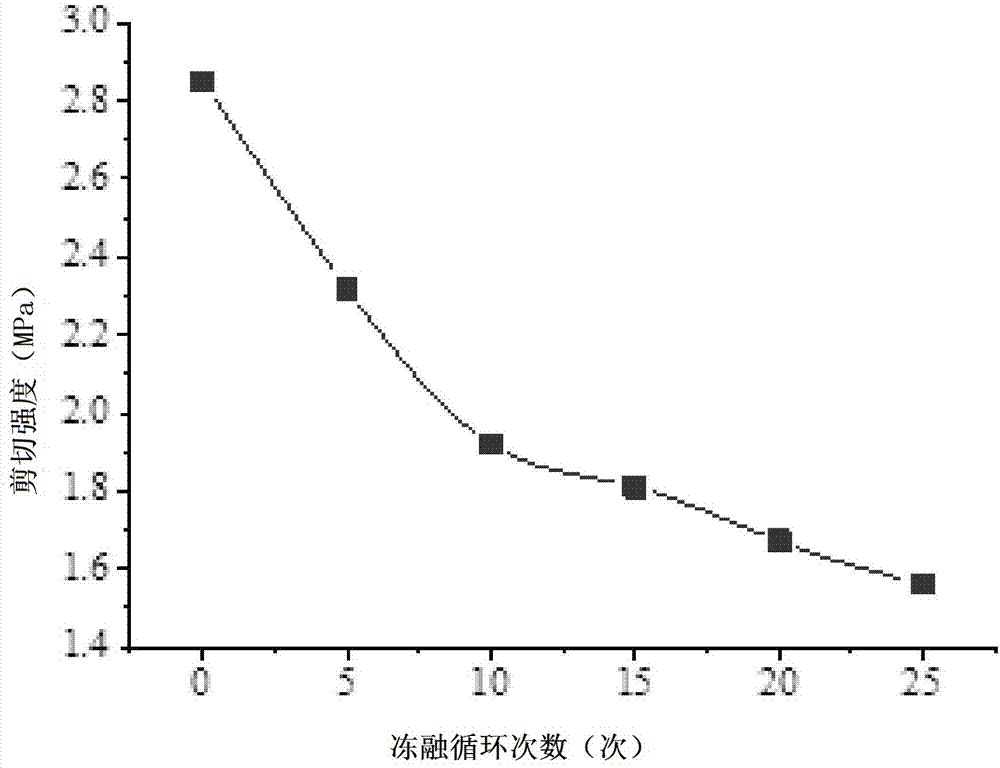

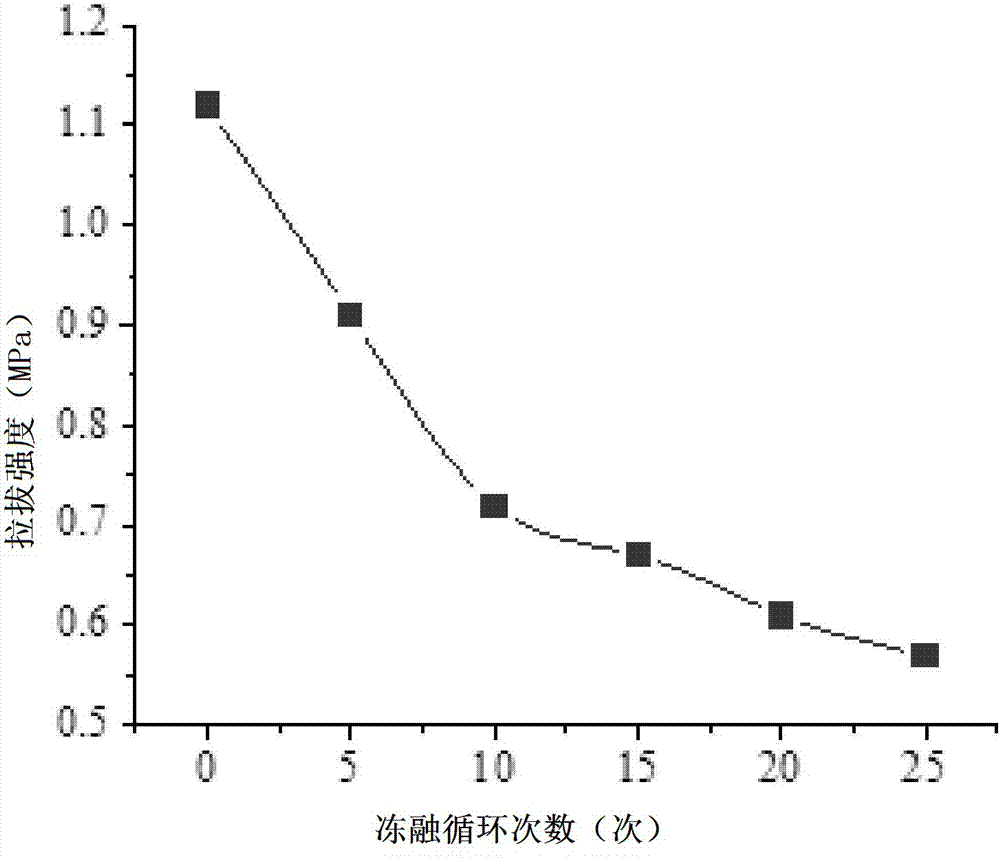

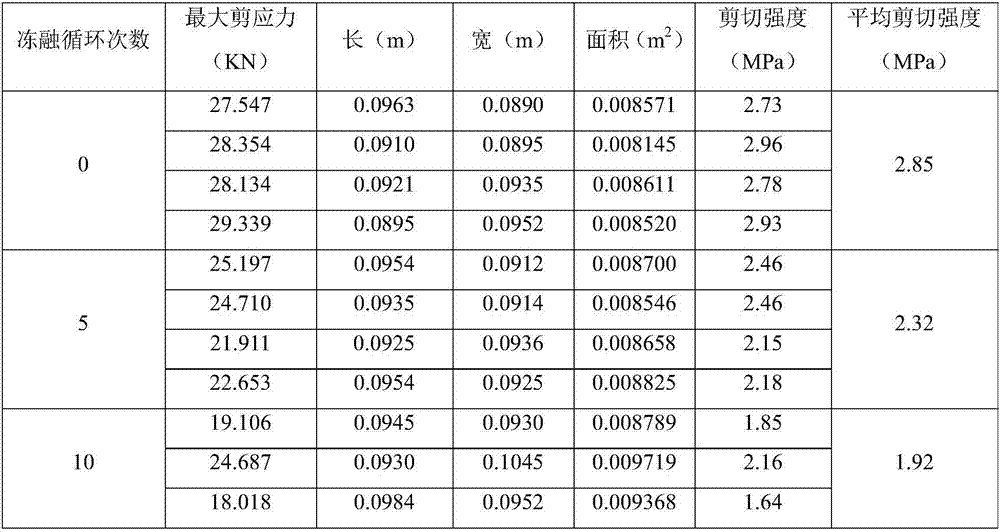

[0072] The shear strength and pull strength of the test pieces were tested, and the test results are shown in Table 3 and Table 4.

[0073] Table 3 The shear strength of the specimen after one freeze-thaw cycle

[0074]

[0075] Table 4 The pull-out strength of the specimen after one freeze-thaw cycle

[0076]

[0077] It can be seen from Table 3 and Table 4 that after one cycle of freezing in a refrigerator at -18°C for 16 hours and thawing in water at 25°C for 24 hours, the shear strength and pull-out strength of the specimen decreased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com