Manufacturing method of chip thermistor and chip thermistor

A technology of thermistor and manufacturing method, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of large tolerance and low temperature coefficient of resistance, etc., and achieve the effect of good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

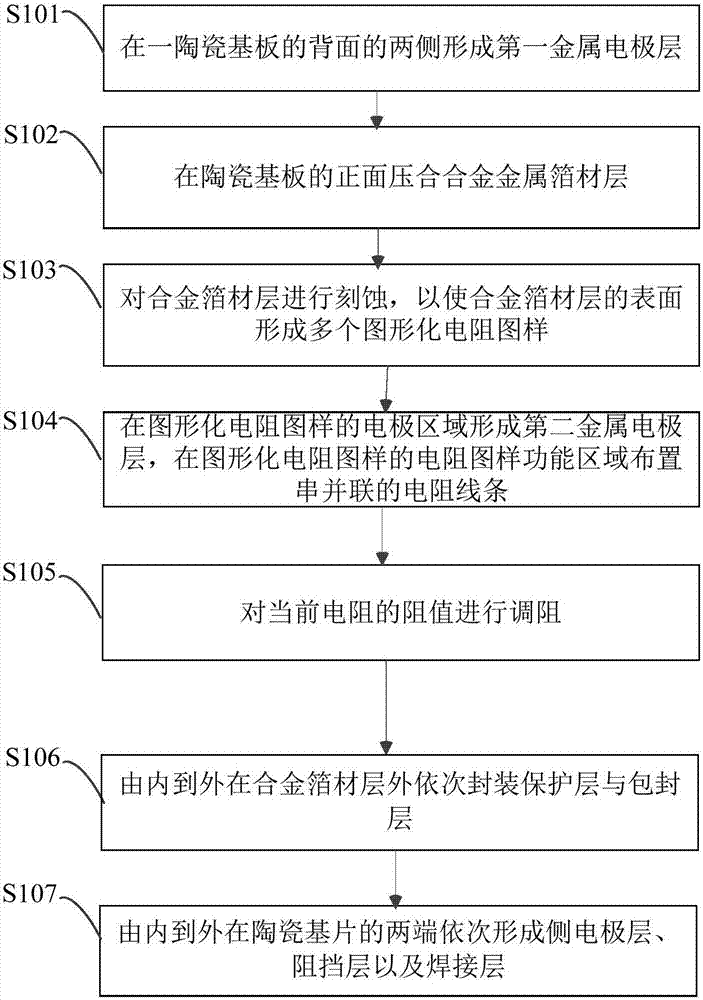

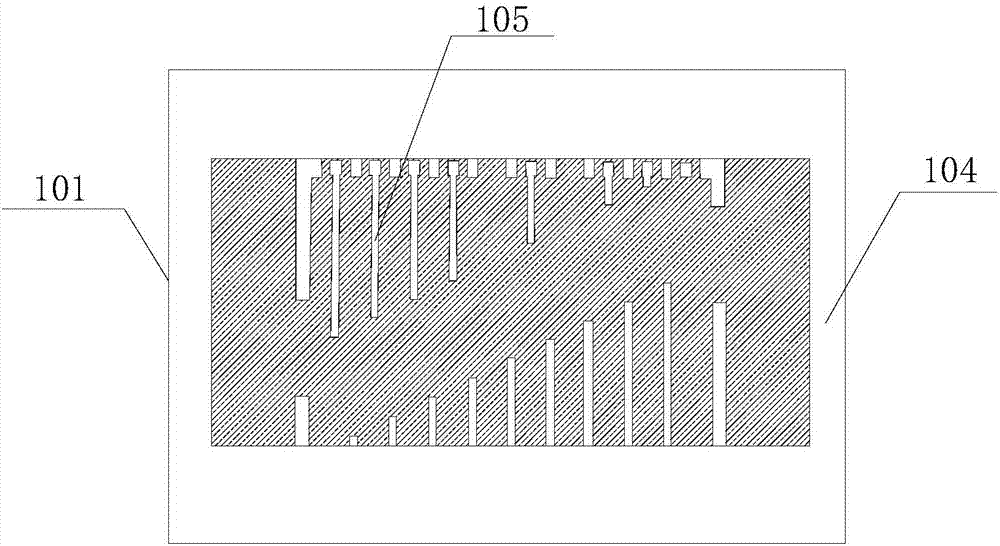

[0047] see figure 1 , the present embodiment provides a chip thermistor manufacturing method, the chip thermistor manufacturing method comprising:

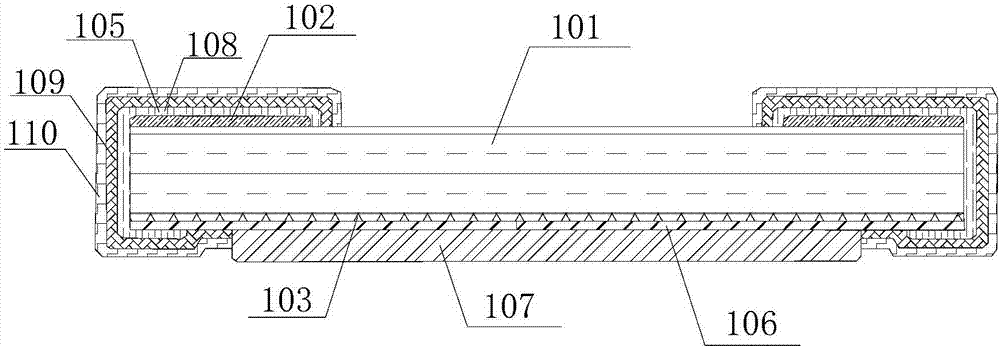

[0048] Step S101 : forming a first metal electrode layer 102 on a predetermined area on the back of a ceramic substrate 101 .

[0049] The ceramic substrate 101 has excellent electrical insulation performance, high thermal conductivity and high adhesion strength, and can be etched with various patterns like a PCB board, and has a large current-carrying capacity. Therefore, the ceramic substrate 101 can be used as a basic material for high-power power electronic circuit structure technology and interconnection technology. In this embodiment, the first metal electrode layer 102 may be formed on a predetermined area on the back of the ceramic substrate 101 by, but not limited to, sputtering, evaporation or screen printing.

[0050] Step S102 : Pressing the temperature-sensitive foil layer 103 on the front surface of the ceramic subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap