Flue-cured tobacco high-temperature forced mature prevention and control agent and application thereof

A control and high temperature technology, applied in the field of tobacco cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

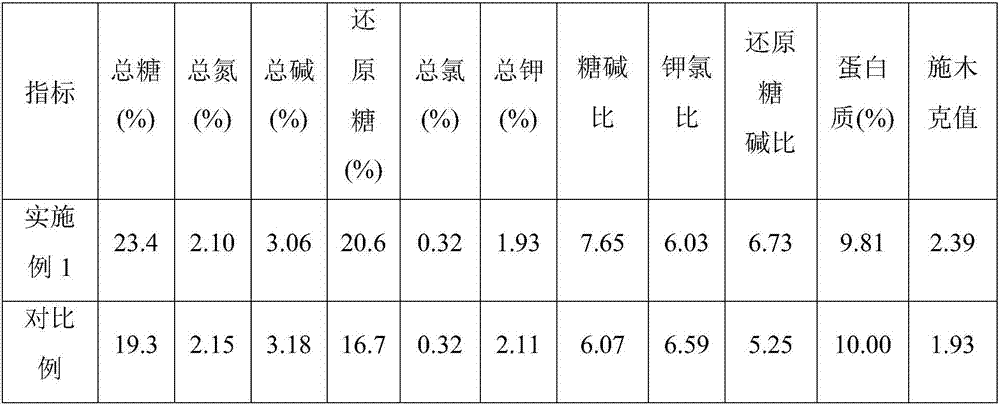

Embodiment 1

[0027] 5 parts by weight of putrescine hydrochloride, 5 parts of sodium nitroprusside, 100 parts of calcium chloride and 200 parts of potassium dihydrogen phosphate are evenly mixed and dissolved in water to obtain a dilution of the preventive and control agent, wherein the flue-cured tobacco is at a high temperature The mass ratio of the ripening prevention and control agent to water is 1:500, and the dilution of the prevention and control agent is sprayed once on each leaf surface in the middle and late stages of tobacco plant vigorous growth and the early stage of maturation, and the interval of spraying twice successively is 10 days. Each dosage is 80kg prevention and control agent dilution / mu.

Embodiment 2

[0029] 5 parts by weight of putrescine, 5 parts of sodium nitroprusside, 150 parts of calcium chloride and 300 parts of potassium dihydrogen phosphate are uniformly mixed and dissolved in water to obtain a dilution of the preventive and control agent, wherein the flue-cured tobacco is forced to ripen at a high temperature The mass ratio of the control agent to water is 1:800, and the dilution of the prevention and control agent is sprayed once on each foliage of the tobacco plant in the mid-growth period and the early stage of maturity, and each dosage is 100kg of the dilution of the prevention and control agent / mu.

Embodiment 3

[0031] 1 part of spermine, 10 parts of sodium nitroprusside, 50 parts of calcium chloride and 100 parts of potassium dihydrogen phosphate calculated in parts by weight are evenly mixed and dissolved in water to obtain a dilution of the preventive and control agent, wherein the high-temperature forced-cooking preventive and control agent for flue-cured tobacco The mass ratio of control agent and water is 1:200, and described prevention and control agent dilution is sprayed 1 time on each foliage of tobacco plant flourishing late stage and mature early stage, and successively two spraying intervals are 8 days, and each consumption is 30kg prevention and control agent dilution / mu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com