Cultivation method for preventing and controlling heat-forced maturity of flue-cured tobacco

A cultivation method and high temperature technology are applied in the field of cultivation for preventing and controlling high temperature ripening of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

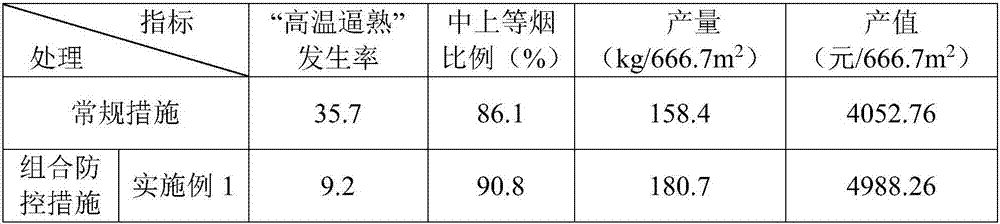

Examples

Embodiment 1

[0034] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the ridge height is 45cm; when transplanting, the hole soil is fully loosened and expanded, and natural peat is applied in the hole, and the application rate of natural peat is 50g (natural dry weight) / plant; mix the natural peat with the hole soil in the horizontal range of about 15cm (radius) around the root system evenly, and the depth range is 15cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant cluster stage, and cover the straw, and the thickness of the straw covering is 3cm; In the later stage of tobacco plant growth, 5 parts by weight of putrescine hydrochloride, 5 parts of sodium nitroprusside, 100 parts of calcium chloride and 200 parts of potassium dihydrogen phosphate are evenly mixed and dissolved in water to obtain the dilution of the preventive and control agent. Wherein the mass ratio of the flue-cured tobacco high-temperatur...

Embodiment 2

[0036] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the height of the ridges is 40cm; when transplanting, the hole soil is fully loosened and expanded, and natural peat is applied in the holes, and the application rate of natural peat is 30g (natural dry weight) / plant; mix the natural peat with the hole soil in the horizontal range of about 15cm (radius) around the root system, and the depth range is 10cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant group stage, and cover the straw, the thickness of the straw covering is 5cm; In the later stage of tobacco plant growth, 5 parts by weight of putrescine, 5 parts of sodium nitroprusside, 150 parts of calcium chloride and 300 parts of potassium dihydrogen phosphate are evenly mixed and dissolved in water to obtain a dilution of the preventive and control agent, wherein the The mass ratio of flue-cured tobacco high temperature ripening preventio...

Embodiment 3

[0038] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the height of the ridges is 50cm; when transplanting, the hole soil is fully loosened and expanded, and artificial peat is applied in the holes, and the application rate of artificial peat is 100g (natural dry weight) / plant; mix the artificial peat with the hole soil in the horizontal range of about 20cm (radius) around the root system, and the depth range is 20cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant group stage, and cover the straw, and the thickness of the straw covering is 3cm; In the later stage of tobacco plant growth, 1 part of spermine, 10 parts of sodium nitroprusside, 50 parts of calcium chloride and 100 parts of potassium dihydrogen phosphate calculated in parts by weight are evenly mixed and dissolved in water to obtain a dilution of the preventive and control agent, wherein the The mass ratio of flue-cured tobacco high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com