Cultivation method capable of preventing and controlling heat-forced maturity of flue-cured tobacco

A cultivation method and high-temperature technology, applied in the cultivation field of preventing and controlling high-temperature forced ripening of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

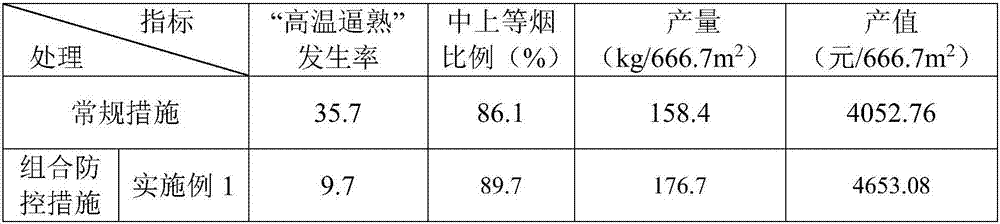

Examples

Embodiment 1

[0033] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the ridge height is 45cm; when transplanting, the hole soil is fully loosened and expanded, and natural peat is applied in the hole, and the application rate of natural peat is 50g (natural dry weight) / plant; mix the natural peat with the hole soil in the horizontal range of about 15cm (radius) around the root system evenly, and the depth range is 15cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant cluster stage, and cover the straw, and the thickness of the straw covering is 3cm; In the later stage of tobacco plant growth, 5 parts by weight of putrescine hydrochloride, 5 parts of sodium nitroprusside, and 30 parts of sodium sulfite are evenly mixed and dissolved in water to obtain a dilution of the control agent, wherein the high-temperature forced ripening of flue-cured tobacco prevents and controls The mass ratio of agent and water is 1:...

Embodiment 2

[0035] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the height of the ridges is 40cm; when transplanting, the hole soil is fully loosened and expanded, and natural peat is applied in the holes, and the application rate of natural peat is 30g (natural dry weight) / plant; mix the natural peat with the hole soil in the horizontal range of about 15cm (radius) around the root system, and the depth range is 10cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant group stage, and cover the straw, the thickness of the straw covering is 5cm; In the later stage of tobacco plant growth, 1 part of putrescine, 10 parts of sodium nitroprusside, and 5 parts of sodium sulfite calculated in parts by weight are evenly mixed and dissolved in water to obtain a dilution of the control agent, wherein the high-temperature ripening control agent for flue-cured tobacco is mixed with water The mass ratio of the control ag...

Embodiment 3

[0037] Before the tobacco seedlings are transplanted, mechanical powder ridges are used, and the height of the ridges is 50cm; when transplanting, the hole soil is fully loosened and expanded, and artificial peat is applied in the holes, and the application rate of artificial peat is 100g (natural dry weight) / plant; mix the artificial peat with the hole soil in the horizontal range of about 20cm (radius) around the root system, and the depth range is 20cm; cover the plastic film after transplanting, remove the plastic film after the tobacco plant group stage, and cover the straw, and the thickness of the straw covering is 3cm; In the later stage of tobacco plant growth, 10 parts by weight of putrescine, 1 part of sodium nitroprusside, and 2 parts of sodium sulfite are evenly mixed and dissolved in water to obtain a dilution of the control agent, wherein the high-temperature ripening control agent for flue-cured tobacco is mixed with water The mass ratio of the control agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com