Guide and guard roller cooling and detecting system

A detection system and technology of guide rollers, which are applied in length measuring devices, guiding/positioning/aligning devices, metal rolling, etc., can solve the problems of heat generation of guide rollers, low degree of automation, and inability to detect real-time temperature of guide rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is realized through the following technical solutions:

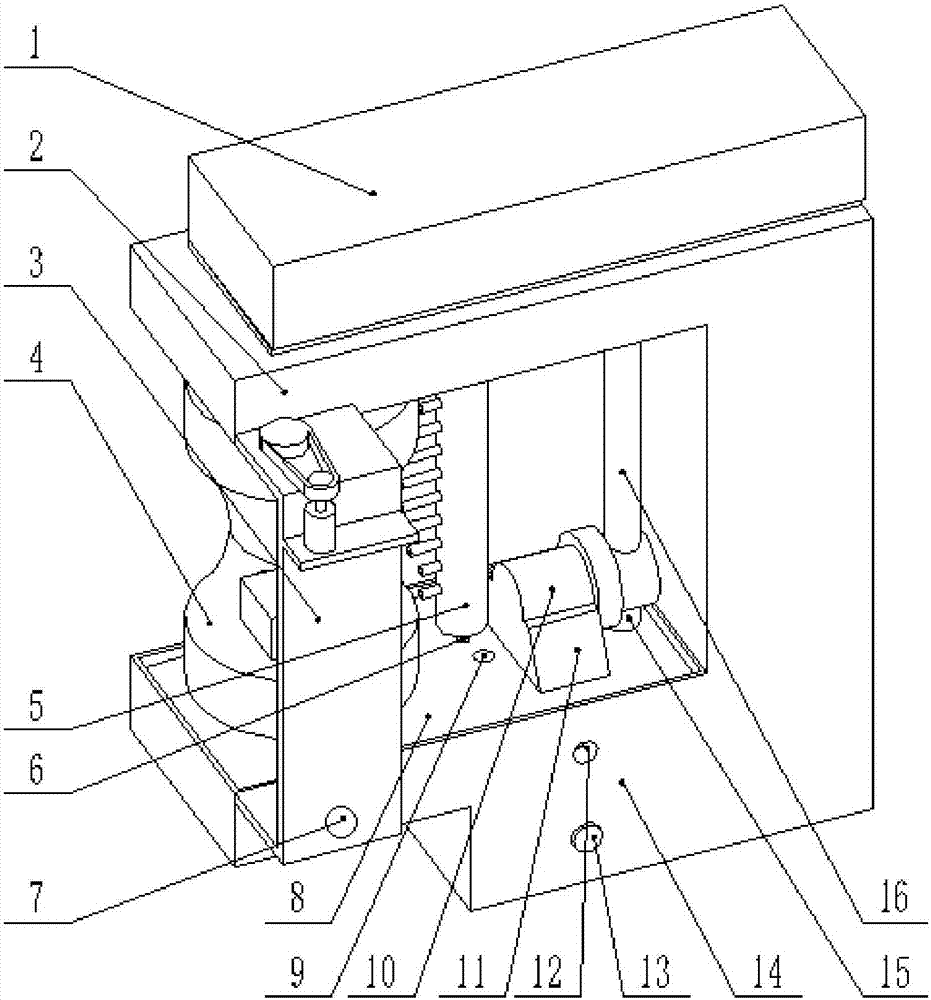

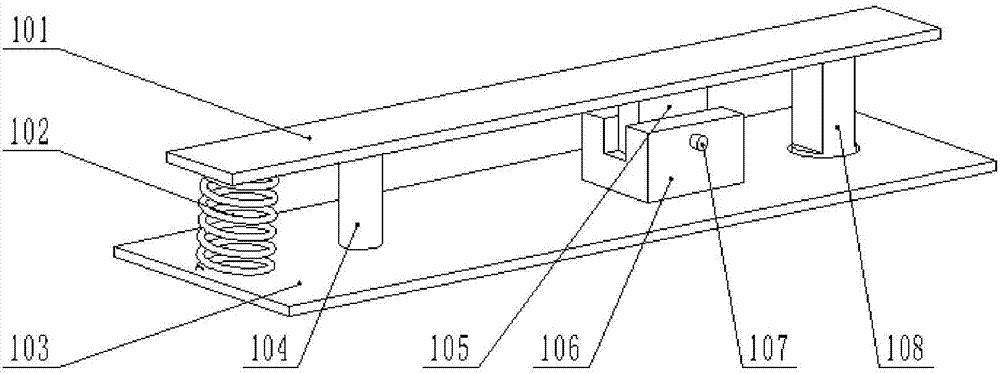

[0020] A guide and guide roller cooling system, including a control system 1, a guide roller arm 2, a detection device 3, a guide roller 4, a cooling device 5, a first plug 6, an indicator light 7, a water storage tank 8, a drainage hole 9, and a water pump 10 , water pump base 11, water inlet 12, second plug 13, water tank 14, water inlet pipe 15 and water outlet pipe 16, the control system 1 is installed on the top of the guide roller arm 2, and the cooling device 5 is installed on the guide roller 4 Next to and connected to the outlet pipe 16, the first plug 6 is installed at the drain 505 in the cooling device 4, the indicator light 7 is installed on the support plate 303, and there is a drain at the bottom of the water storage tank 8 The hole 9 is connected with the water tank 14, the water pump 10 is installed on the bottom of the water storage tank 8 through the water pump base 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com