Guide guard anti-iron filings clogging type circulation cooling device

A circulating cooling and clogging technology, which is applied in the field of steel rolling, can solve the problems of low automation of guide roller cooling and clogging of iron filings, etc., and achieve the effect of saving energy and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

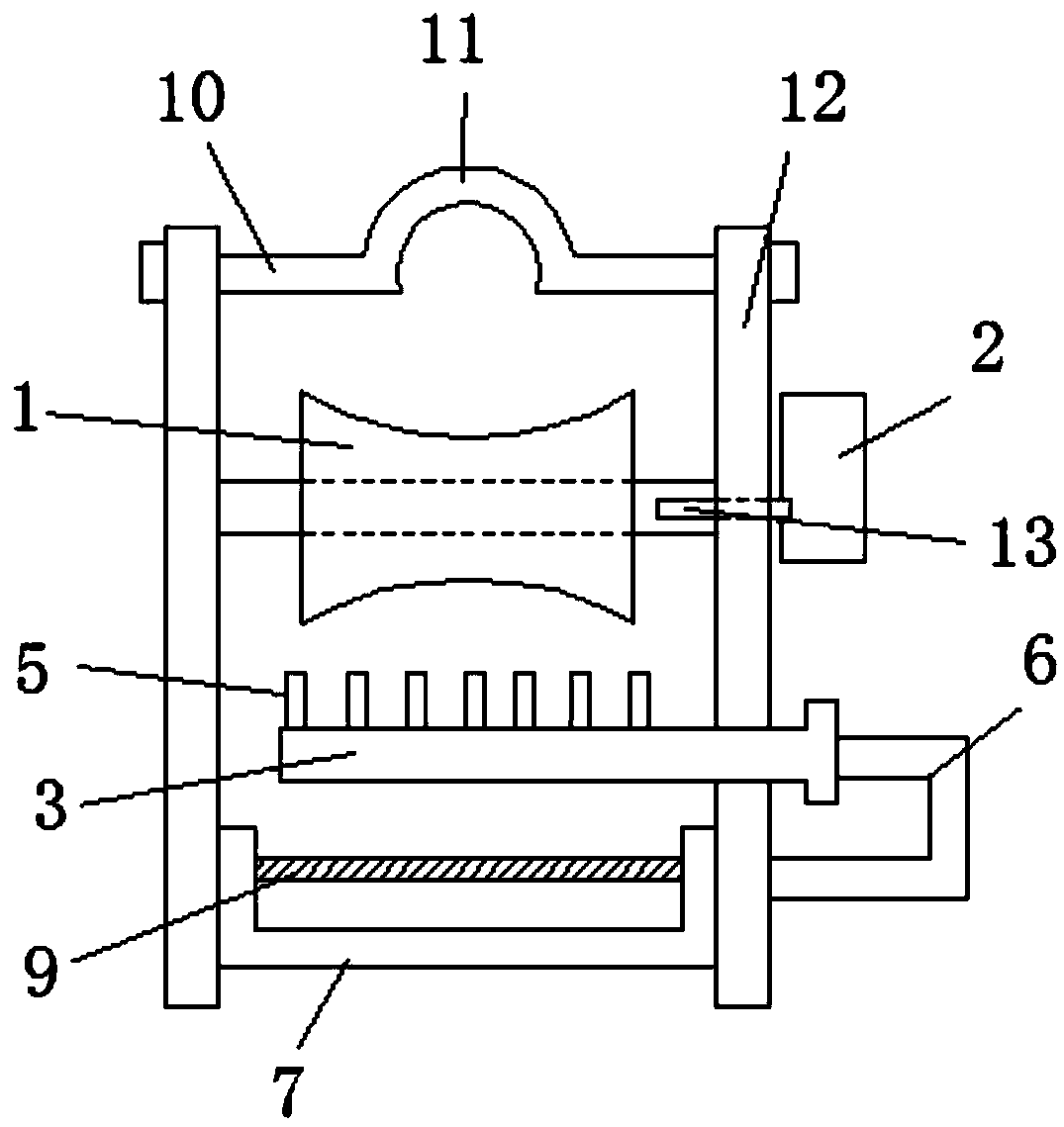

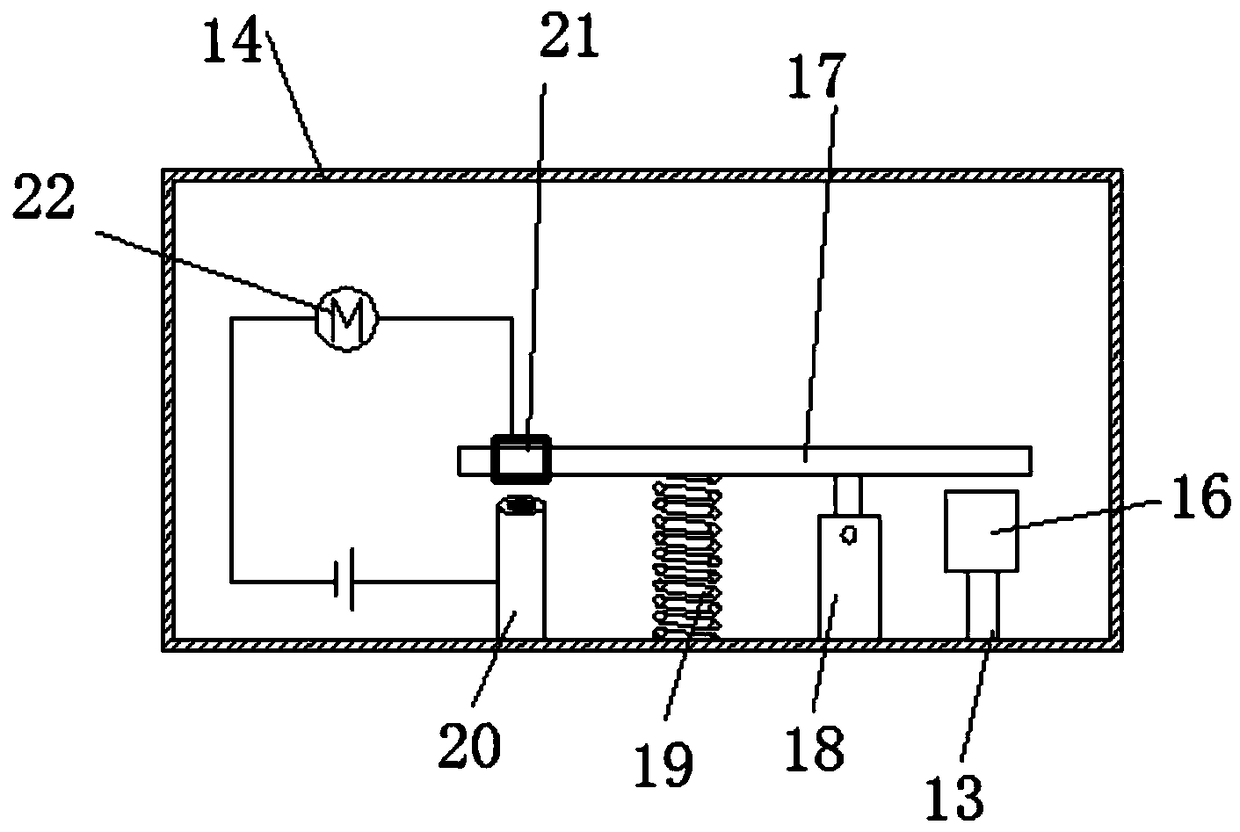

[0012] Referring to the accompanying drawings, a guide and guard anti-iron filings blockage type circulation cooling device includes a guide roller 1, a temperature control system 2 and a cold water pipe 3, a cold water pipe 3 is arranged above the guide roller 1, and the outer wall of the cold water pipe 3 is close to One side of the guide roller 1 is fixedly connected with a plurality of spouts 5, and one end of the cold water pipe 3 is provided with a water supply pipeline 6, and the water supply pipeline 6 is connected to a reservoir 7, the reservoir 7 is located below the guide roller, and the reservoir The side wall of the pool 7 is connected with a water supply pipeline 6, a filter layer 9 is provided in the reservoir 7, a stop bar 10 is provided above the guide roller 1, and a stop bar 10 is arranged at the middle section of the stop bar 10. The guide groove 11 is limited, and the two ends of the guide roller 1 are respectively connected to the guide roller arm 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com