A processing method of high flatness metal ultra-thin plate

A processing method and ultra-thin plate technology, applied in the field of abrasive grain processing, can solve the problems that cannot be adopted, can not realize high-flatness metal ultra-thin plate processing, clamping deformation and deformation are difficult to control, etc., so as to achieve easy control of deformation and avoid surface Unstable shape and effective control of clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

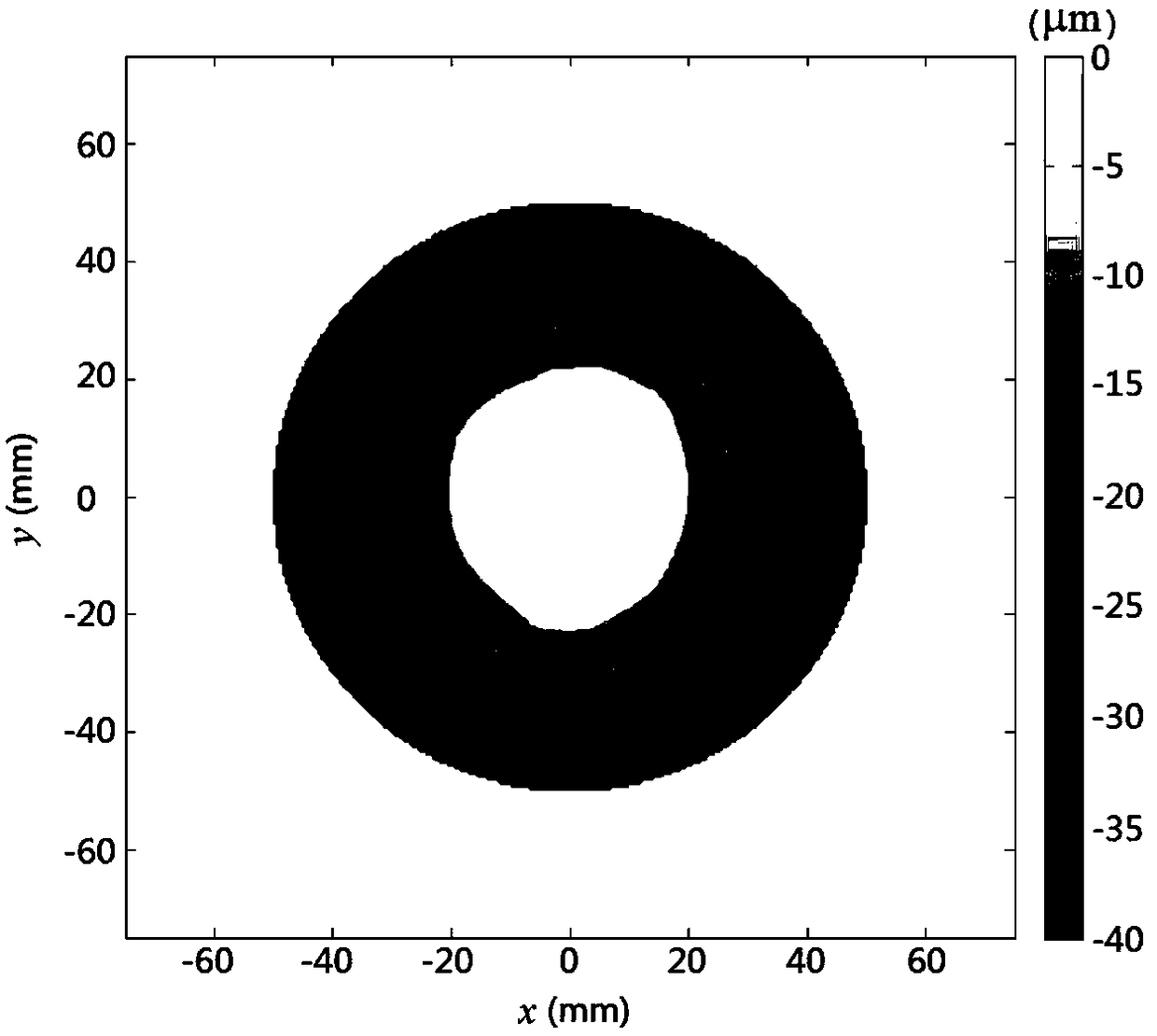

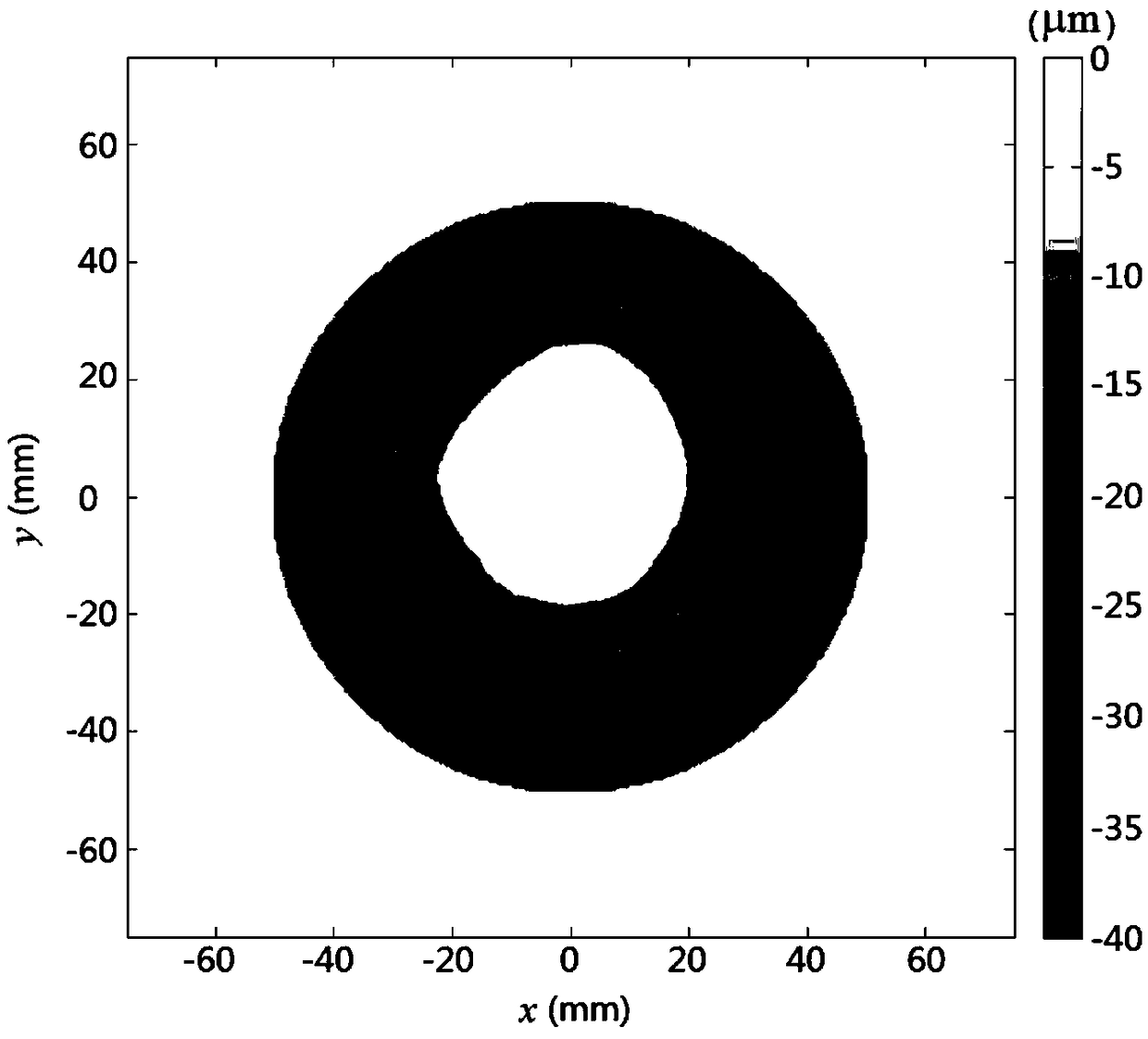

[0036] An ultra-thin copper plate for testing, the material is T2 pure copper, the required diameter is 150mm, the thickness is 3mm, the diameter-to-thickness ratio is 50, and the surface shape accuracy reaches PV<10μm within the effective diameter range of 120mm.

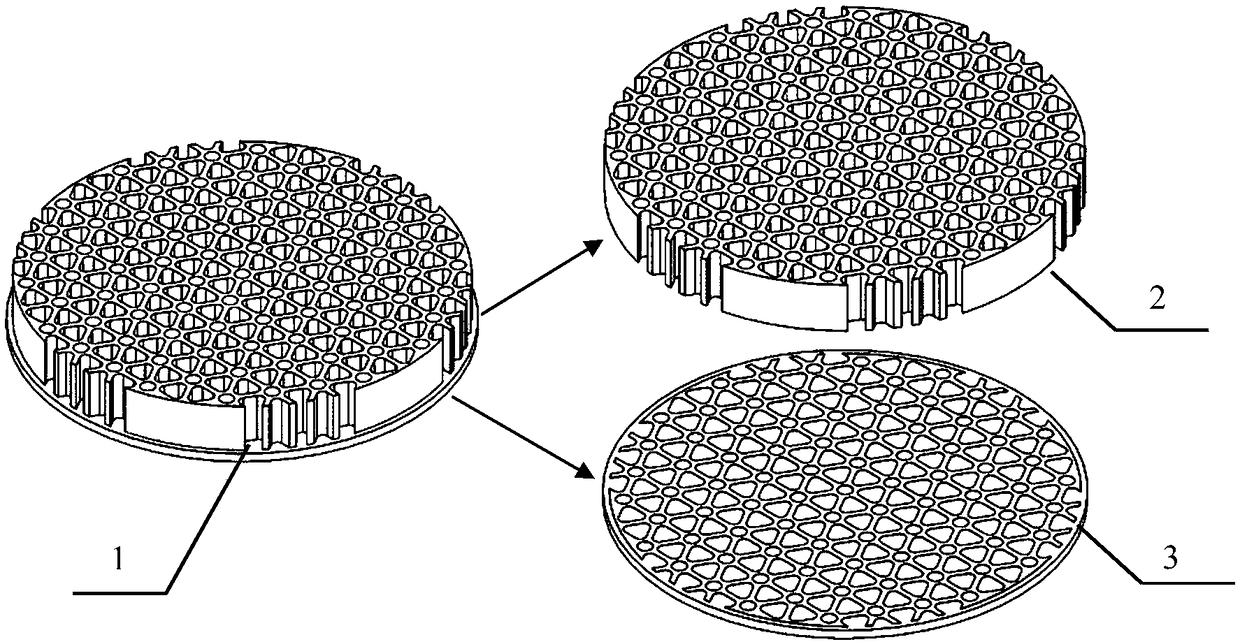

[0037] The initial size of the copper block is 150mm in diameter and 20mm in thickness. On one side, blind holes with a depth of 16.5mm and an equivalent diameter of 6-10mm are processed by milling technology. The wall thickness between the holes is 2mm. Carry out stress-relief annealing on hollow blank 1 to eliminate residual stress, annealing temperature is 280° C., heat preservation for 4 hours, and furnace cooling. The hollow support structure 3 can effectively reduce the internal residual stress after annealing, thereby effectively suppressing the additional deformation cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com