Clamping and releasing mechanism for robot arm

A technology of robot arm and release mechanism, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of opening and closing force changes, easily damaged round rod material surface, and affecting production and processing efficiency, so as to meet the needs of use and structure Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

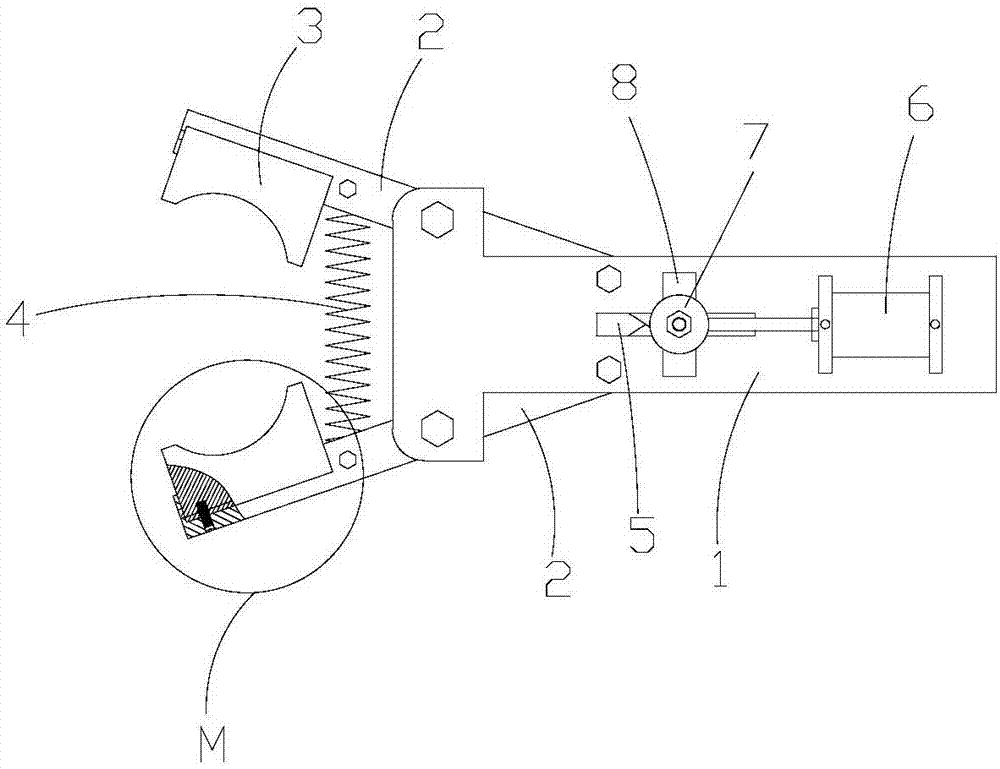

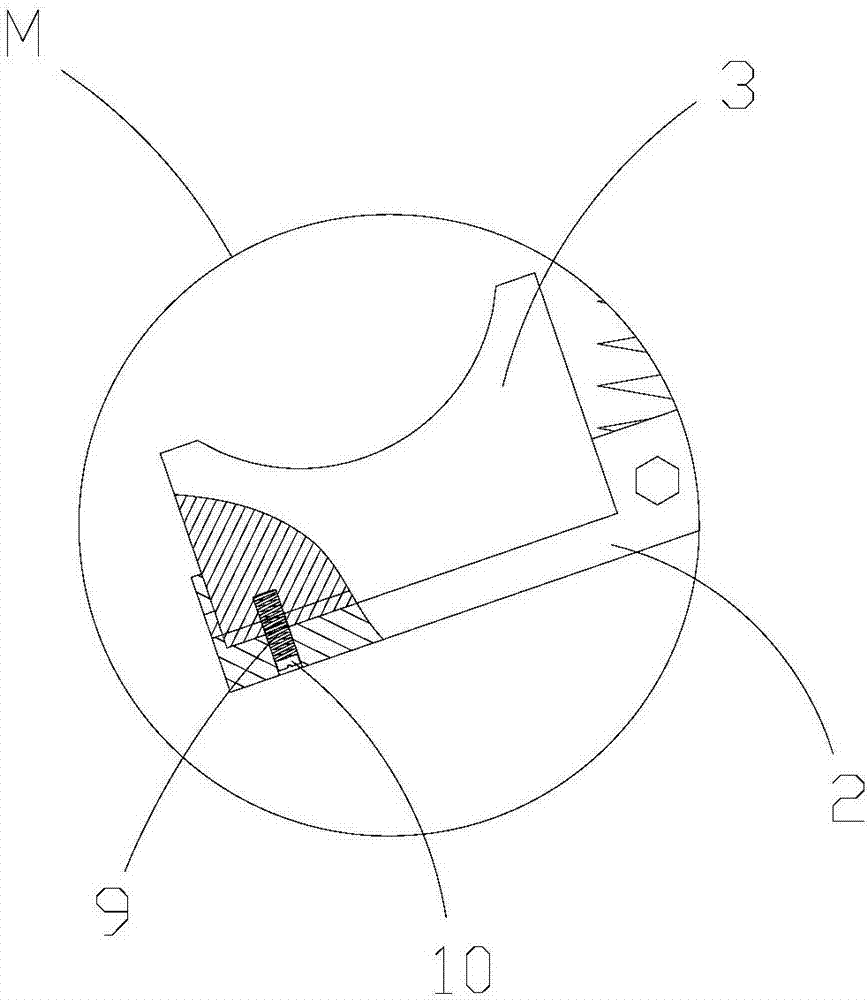

[0013] Such as figure 1 and figure 2 The shown clamping and releasing mechanism for a robot arm includes a base 1, a clamping arm 2, an elastic block 3, a tension spring 4, a telescopic cylinder 6, a central shaft lock nut 7, an extension plate 8, a spring 9 and an adjusting bolt 10. The base 1 is provided with a strip-shaped sliding groove 5, and the two clamping arms 2 are installed in the sliding groove 5 through the cross-rotation of the central axis lock nut 7, and the clamping arms 2 slide through the waist-shaped hole structure Installed on the base 1, the jaws of the elastic block 3 are arranged in a circular arc surface structure, and the elastic block 3 is movably installed on the inside of the clamping arm 2 through a buckle structure, and the clamping arm 2 is provided with a The spring hole, the spring 9 and the adjusting bolt 10 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com