A fully automatic packaging equipment

A fully automatic packaging and automatic technology, applied in packaging, packaging machines, transportation packaging, etc., can solve problems such as high labor costs, low work efficiency, and inability to adapt to enterprise production capacity requirements, so as to improve efficiency, reduce requirements, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

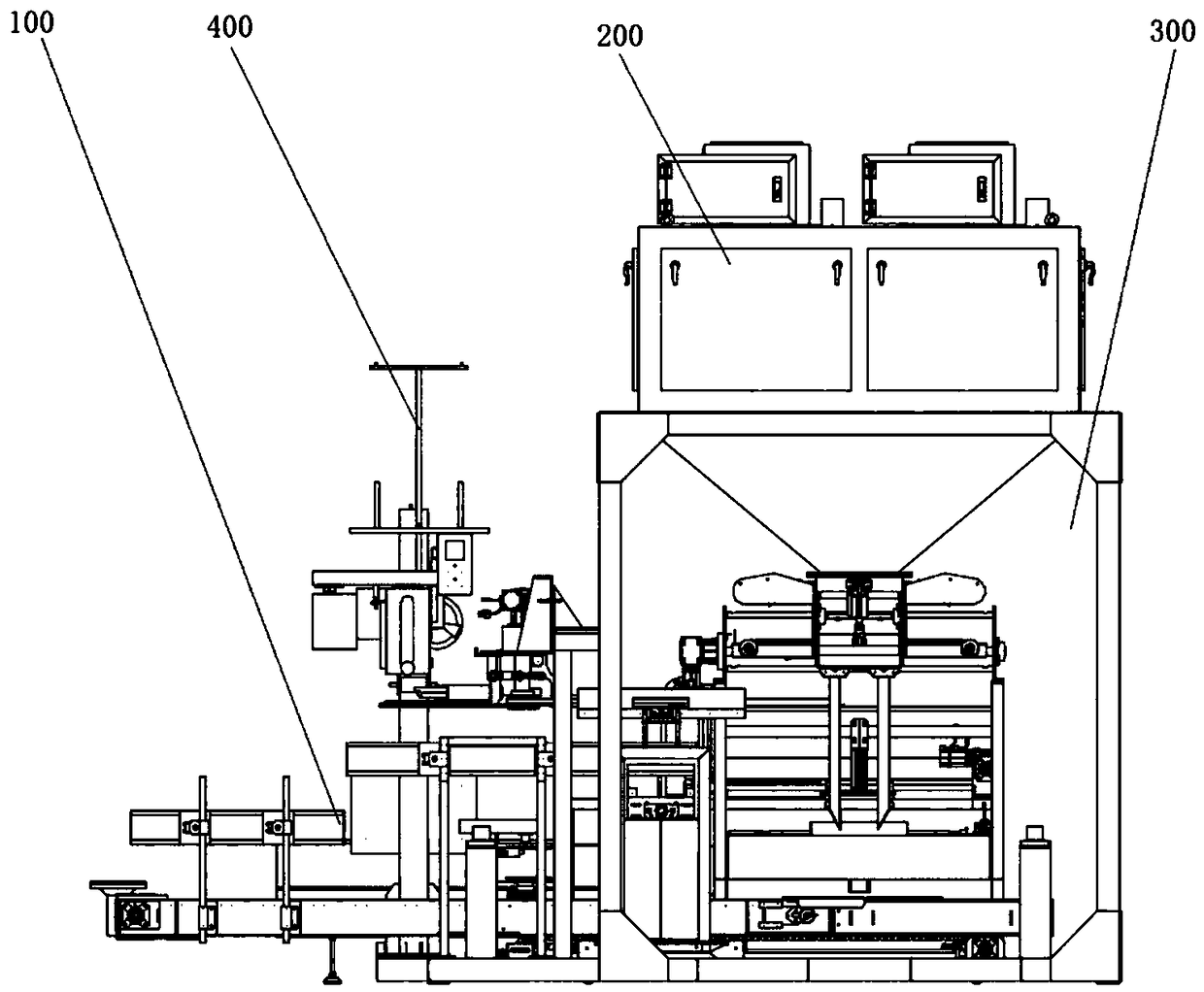

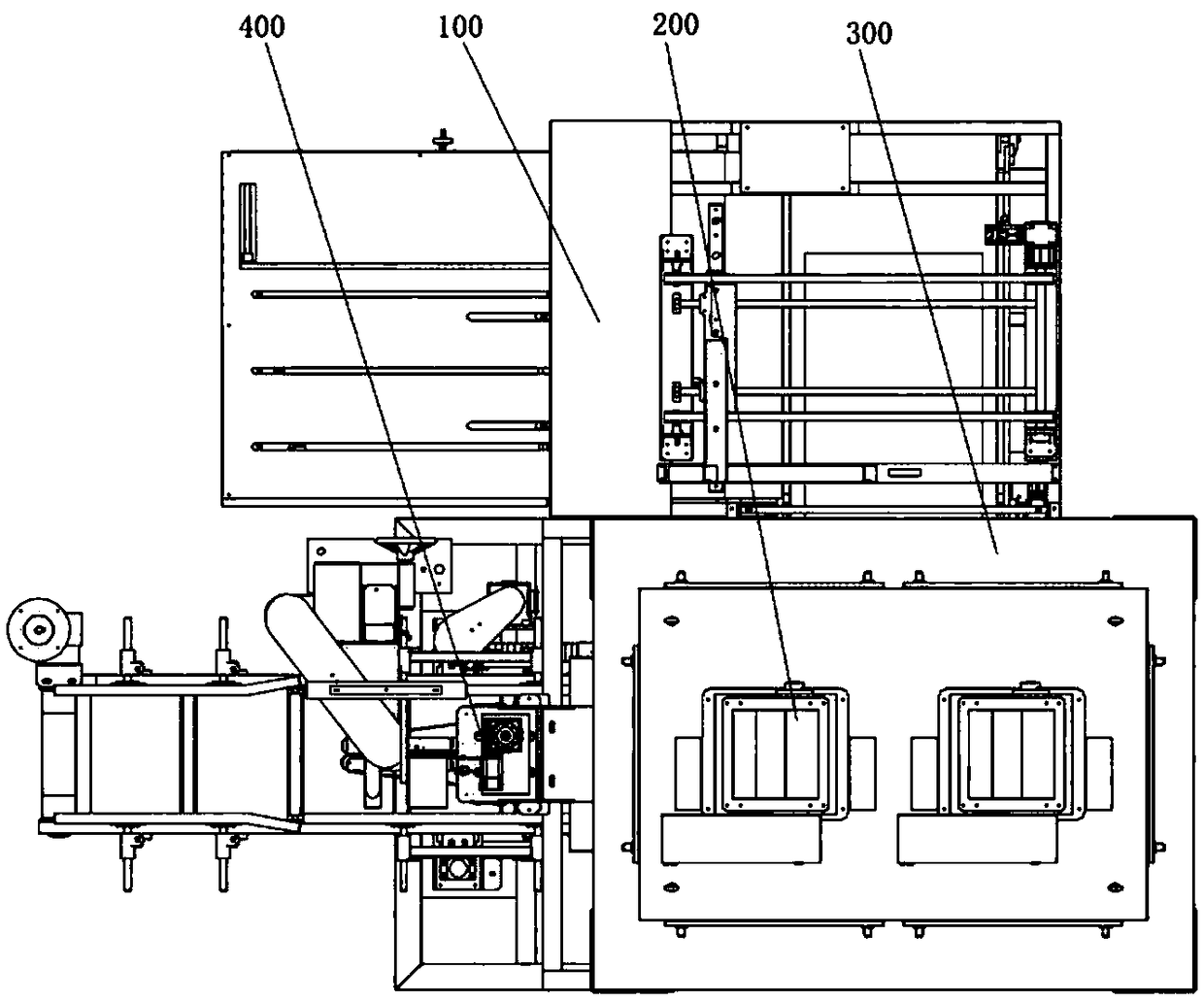

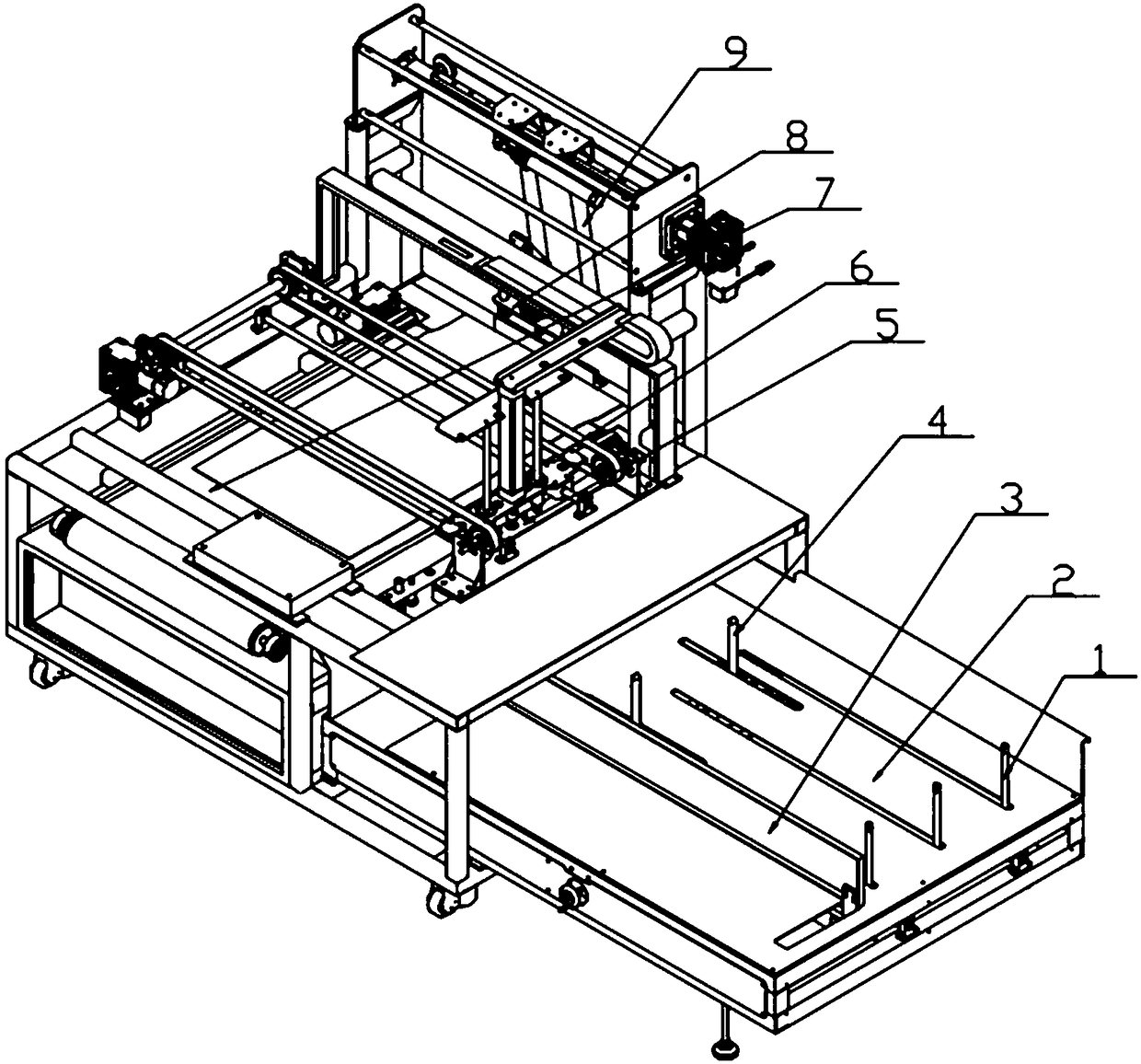

[0025] Such as Figure 1-6 As shown in one of them, the present invention discloses a fully automatic packaging equipment, which includes an automatic bag loading machine 100, an automatic quantitative packaging scale 200, an automatic bag sorting machine 300 and an automatic bag sewing machine 400; image 3 As shown, the automatic bag loading machine 100 includes a bag-moving cylinder, a positioning cylinder, a bag-taking cylinder, a conveyor 7, and a bag holder 2 for placing packaging bags. The middle section of the plate 2 is provided with a bag width positioning rod 4, and the bag width positioning rod 4 is horizontal or vertical to the upper surface of the bag holding plate 2 under the drive of a driving cylinder, and the bag pushing rod 1 is driven by the bag moving cylinder along the support. The bag plate 2 slides between the middle section of the bag support plate 2 and one end of the bag support plate 2 in the length direction, and the bag width positioning rod 4 sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com