Compacting material bin applied to plastic film cleaning and recycling production line

A plastic film and production line technology, which is applied in the direction of tanker, packaging, loading/unloading, etc., can solve the problems that affect the working efficiency of the plastic film recycling production line, the low packing density of film materials, and affect the product quality, so as to reduce the volume and storage capacity High, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

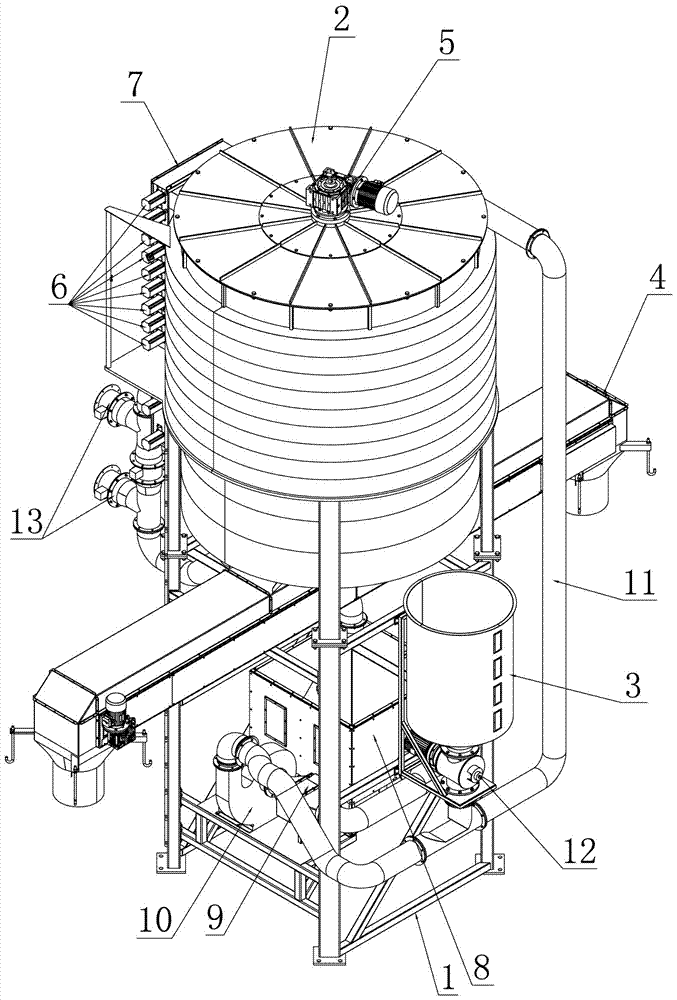

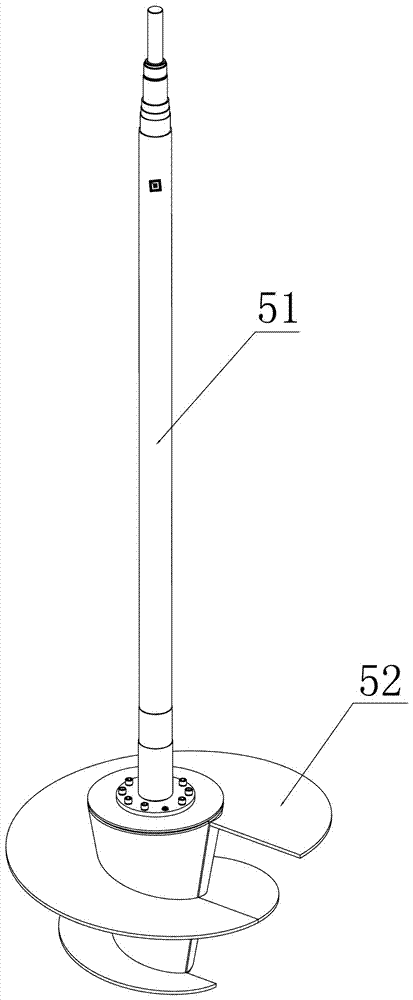

[0011] Such as figure 1 , figure 2 As shown, the compacting bin in the plastic film cleaning and recycling production line includes: a frame 1, and a storage hopper 2 and a feed hopper 3 installed on the frame 1, and an annular vertical hopper is arranged in the storage hopper 2. Straight partitions and ring-shaped vertical partitions divide the interior of the storage hopper into relatively independent inner chambers and outer ring chambers. There is a discharge port at the bottom of the inner chamber of the storage hopper 2. The discharge port and the reversible conveyor The feeding port of 4 is connected, and the inner chamber of the storage hopper 2 is provided with a vertical screw conveyor 5 for transporting the material in the storage hopper 2 from the discharge port to the reversible conveyor 4; in the storage hopper 2 A number of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com