Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

A polymerized, flame retardant technology, applied in the field of flame retardants and their preparation, can solve the problems of large amount of flame retardants, poor flame retardant efficiency, poor compatibility, etc., achieve mild conditions and improve flame retardant. Efficiency, overcoming the effect of easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

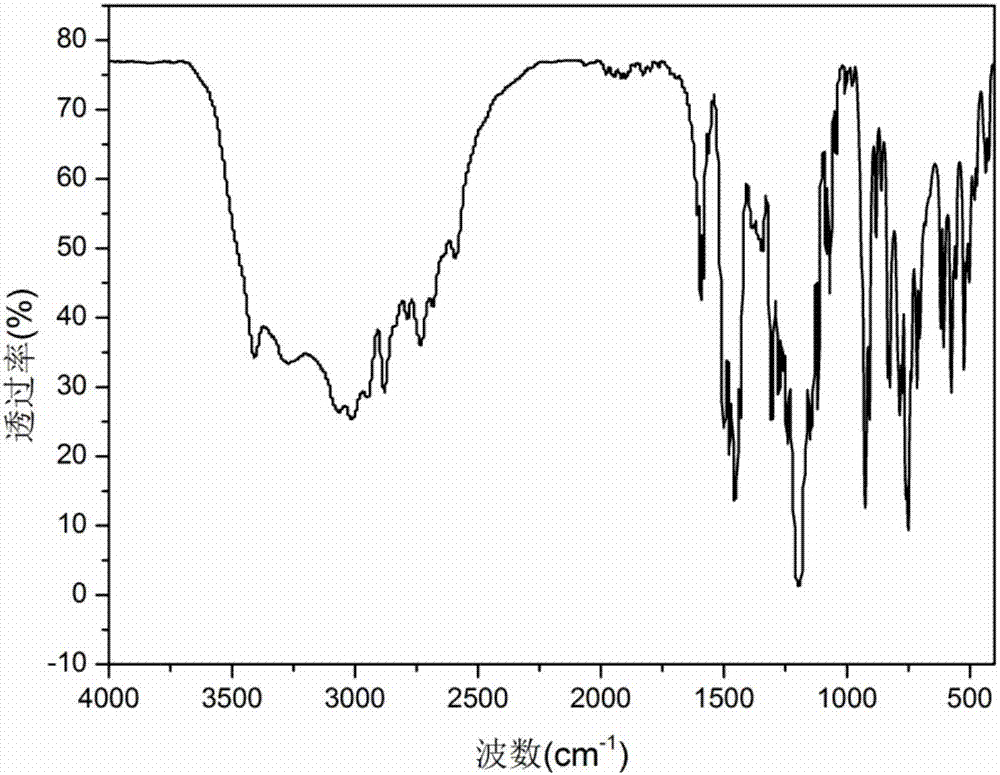

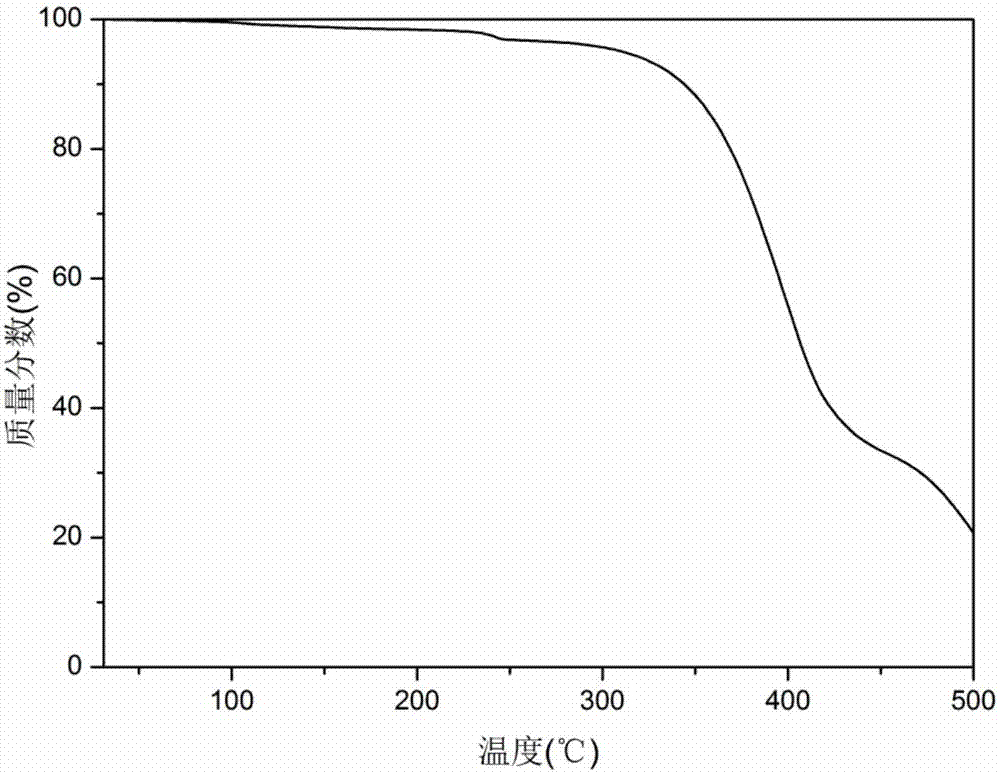

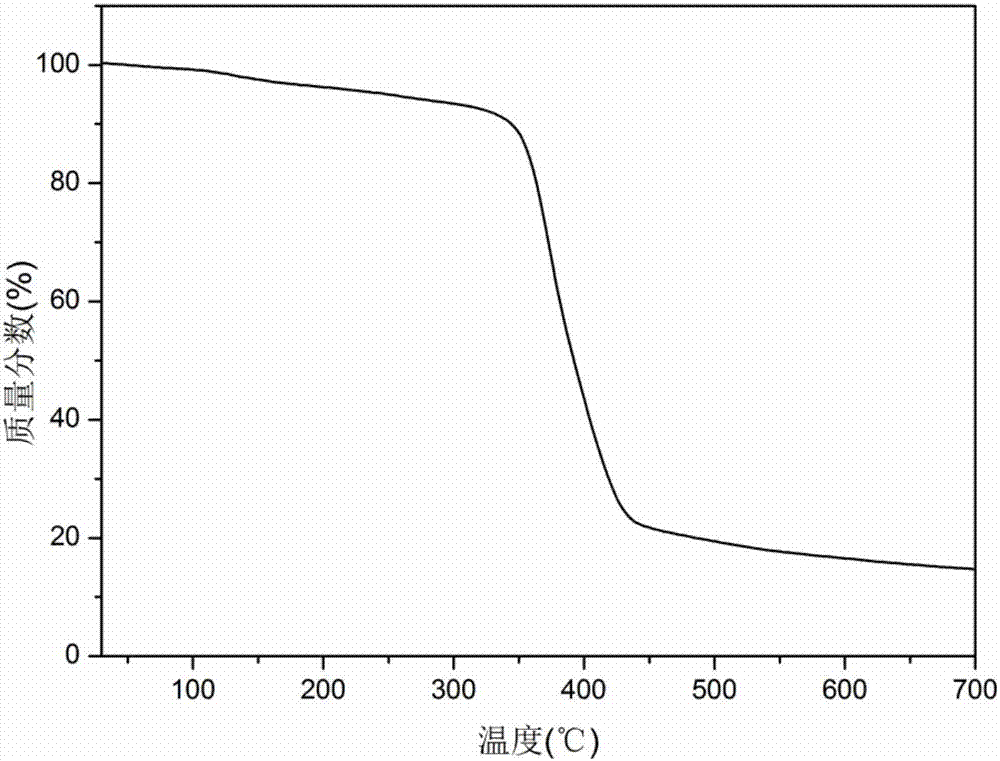

[0035] A preparation method of a phosphorus-containing, silicon-polymerized flame retardant, the steps of which are:

[0036] Weigh 1.6g ODOPB (5mmol) and 1.0g triethylamine (10mmol) into a 100mL three-necked flask, and add 50ml N,N-dimethylformamide (DMF for short), ultrasonically dissolve it completely and put it into a magneton , device buret, condenser, nitrogen device, heat up to 40 ° C, and weigh 0.645g dimethyldichlorosilane (abbreviated as DCDMS, 5mmol) at the same time, add 7ml DMF to dilute, and add it to the burette, slowly add DCDMS / The DMF solution was dropped in about 2 hours, and kept at this temperature for 1 hour after the drop. After the reaction, the reaction system was added to about 5 times of methanol to precipitate the product, vacuum filtered, the filter cake was washed twice with methanol, and dried in a vacuum oven (90kPa) at 80°C for 10h to obtain 1.65g of a yellowish powder. Yield 88%.

Embodiment 2

[0038] A preparation method of a phosphorus-containing, silicon-polymerized flame retardant, the steps of which are:

[0039] Weigh 1.6g ODOPB (5mmol) and 1.9g pyridine (25mmol) into a 100mL three-neck flask, and add 50ml tetrahydrofuran (THF), ultrasonically dissolve it completely and put it into a magnet, install a burette, a condenser, a nitrogen device, and heat up To 60°C, weigh 0.705 methylvinyldichlorosilane (DCMVS, 5mmol) and add 12ml THF to dilute it, and add it to the burette, slowly add DCMVS / THF dropwise under magnetic stirring, and drop it for about 1 hour. Temperature reaction 4h. After the reaction, add the reaction system to water about 10 times the volume of the reaction solution to precipitate the product, vacuum filter, wash the filter cake twice with distilled water, put it in a 60°C oven for 8 hours under vacuum (86kPa), and obtain 1.51g of orange Powder, yield 78%.

Embodiment 3

[0041] A preparation method of a phosphorus-containing, silicon-polymerized flame retardant, the steps of which are:

[0042] Weigh 1.6g ODOPB (5mmol) and 1.7g imidazole (25mmol) into a 100mL three-necked flask, and add 50ml N, N-dimethylformamide (DMF for short), ultrasonically dissolve it completely and put it into a magnet, and install a burette , condenser tube, nitrogen device, heat up to 60°C, weigh 0.705g of methylvinyldichlorosilane (DCMVS for short, 5mmol) and add 10ml of DMF to dilute, and add it to the burette, and slowly add the DCMVS / DMF solution dropwise under magnetic stirring , After about 1 hour of dripping, keep this temperature for 6 hours after dripping. After the reaction, the reaction system was added into water about 10 times the volume of the reaction solution to precipitate the product, vacuum filtered, the filter cake was washed twice with distilled water, and dried in a vacuum oven at 60°C for 11 hours under vacuum (82kPa) to obtain 1.78g Yellow pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com