Cooling medium and cooling device for surface cooling treatment of oil-based drilling fluid

An oil-based drilling fluid and cooling medium technology, which is applied in the fields of refrigerators, refrigeration and liquefaction, heat exchange materials, etc., can solve the problems that the steering tool system cannot adapt, the drilling operation cannot be carried out, and the tool signal transmission is abnormal. Small footprint, improved stability, and the effect of not easy to aggregate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

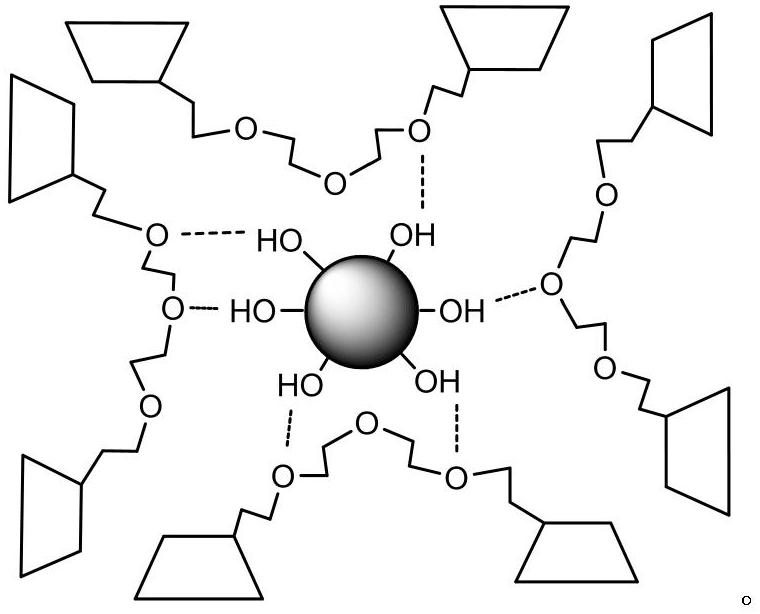

[0026] A cooling medium used for surface cooling treatment of oil-based drilling fluid in high-temperature wells. The specific preparation method: add 100 kg of ethylene glycol with a mass fraction of 98% into a 2.0 cubic meter enamel stirring tank, and add 0.5 kg of ethylene glycol under stirring at 60 rpm Triethylene glycol bridged cyclodextrin and 0.8kg of 20nm-40nm metal copper nanoparticles, after continuing to stir for 15min, add 0.25kg of sodium dodecylbenzenesulfonate and 40kg of water, increase the speed to 2000rpm, stir for 15min, and obtain complex matching cooling medium.

Embodiment 2

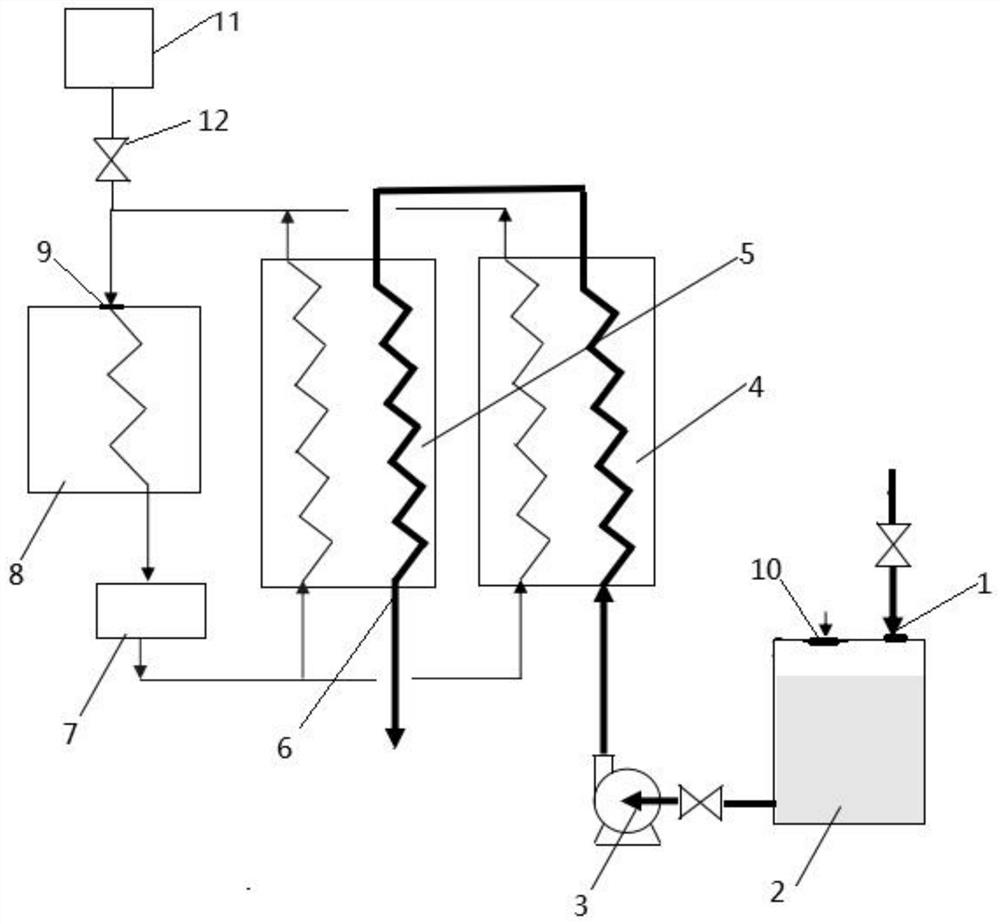

[0028] Such as figure 1 As shown, the cooling device used in conjunction with the cooling medium provided by the present invention has a structure comprising: a drilling fluid storage tank 2, a primary plate cooler 4, a secondary plate cooler 5, an ultrasonic radiation tank 7, and a water chiller 8.

[0029] The plate bundles of the first-stage plate cooler and the second-stage plate cooler are arranged vertically. The plate material is SS30408 stainless steel, the drilling fluid is on the wide channel side, and the channel spacing is 12mm. The cooling medium is on the narrow channel side, and the channel spacing is 8mm. The top of the drilling fluid storage tank is provided with a drilling fluid inlet 1 and a nitrogen injection hole 10 . The space above the liquid level in the drilling fluid storage tank is filled with nitrogen to protect the drilling fluid and prevent the drilling fluid from contacting with air. The liquid outlet at the lower part of the drilling fluid ...

Embodiment 3

[0033] In Example 1, the triethylene glycol bridged cyclodextrin was changed to 0.7 kg, the metal copper nanoparticles were changed to 1.0 kg, and the addition of other components remained unchanged to obtain a composite cooling medium.

[0034] The cooling medium is used in conjunction with the cooling device in Example 2. After cooling the 70°C oil-based drilling fluid, the measured temperature of the low-temperature drilling fluid discharged from the secondary plate heat exchanger 5 is 28.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com