Environmentally friendly anti-high and low temperature rubber oil-sealing material and preparation method thereof

A technology of high and low temperature resistance, rubber oil seal, applied in the field of environmental protection high and low temperature resistance rubber oil seal and its preparation, can solve the problems of high price and restrict wide application, and achieve the effect of excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

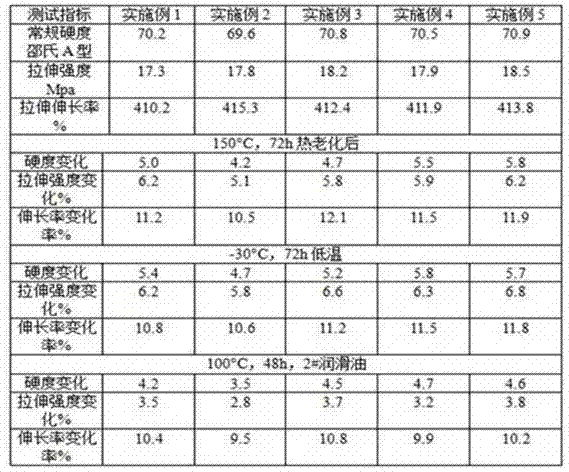

Examples

Embodiment 1

[0018] An environmentally friendly high and low temperature resistant rubber oil seal material, prepared from the following components in parts by mass: 85 parts of nitrile rubber, 15 parts of nano-carbon fiber powder, 40 parts of white carbon black, 5 parts of spray carbon black, 8 parts of zinc oxide, oxidized 2 parts of iron, 3 parts of cerium oxide, 1 part of stearic acid, 2 parts of sulfur, 10 parts of dibutyl phthalate, 8 parts of dioctyl phthalate, 3 parts of polyethylene oxide, 2 parts of carbon black dispersant Parts, 1 part of 4-aminodiphenylamine, 1 part of 2,2-dithiodibenzothiazole, 1.5 parts of tetraethylthiuram disulfide, 1 part of tellurium diethyldithiocarbamate, silane coupling 2 parts of agent, 5 parts of release agent.

[0019] The preparation method of the above-mentioned environmental protection high and low temperature resistant rubber oil seal is as follows: (1) Weigh a raw material according to the above-mentioned mass ratio, and mix nitrile rubber, car...

Embodiment 2

[0021] An environmentally friendly high and low temperature resistant rubber oil seal material, prepared from the following components in parts by mass: 75 parts of nitrile rubber, 10 parts of nano-carbon fiber powder, 30 parts of carbon black, 5 parts of zinc oxide, 4 parts of iron oxide, and 5 parts of cerium oxide 2 parts, 2 parts of stearic acid, 1 part of sulfur, 8 parts of dibutyl phthalate, 6 parts of dioctyl phthalate, 2 parts of oxidized polyethylene, 1 part of carbon black dispersant, 4-aminodiphenylamine 0.5 parts, 0.5 parts of 2,2-dithiodibenzothiazole, 1 part of tetraethylthiuram disulfide, 1.5 parts of tellurium diethyldithiocarbamate, 1 part of silane coupling agent, release agent 3 copies.

[0022] The preparation method of the above-mentioned environmental protection high and low temperature resistant rubber oil seal is as follows: (1) Weigh a raw material according to the above-mentioned mass ratio, and mix nitrile rubber, carbon fiber powder, zinc oxide, iro...

Embodiment 3

[0024] An environmentally friendly high and low temperature resistant rubber oil seal material, which is prepared from the following components in parts by mass: 78 parts of nitrile rubber, 12 parts of nano-carbon fiber powder, 32 parts of white carbon black, 2.5 parts of spray carbon black, 6 parts of zinc oxide, oxidized 2.4 parts of iron, 3.2 parts of cerium oxide, 1.2 parts of stearic acid, 1.5 parts of sulfur, 8.5 parts of dibutyl phthalate, 6.5 parts of dioctyl phthalate, 2.2 parts of polyethylene oxide, 1.2 parts of carbon black dispersant Parts, 0.8 parts of 4-aminodiphenylamine, 0.6 parts of 2,2-dithiodibenzothiazole, 1.4 parts of tetraethylthiuram disulfide, 1.1 parts of tellurium diethyldithiocarbamate, silane coupling 1.2 parts of agent, 3.5 parts of release agent.

[0025] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com