Assembled wallboard and piled slab combined soilless roadbed

A technology of pile-slab combination and soil subgrade, which is applied in the direction of roads, roads, and foundation structure engineering, can solve the problems of low industrialization level, difficult settlement of soft soil foundation, and high engineering cost, achieving moderate cost, eliminating the need for connection methods, The effect of reducing the requirements for hoisting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means realized by the present invention, the novel features created, the purpose achieved and the effects achieved clearly understood, the present invention will be further described below in conjunction with specific illustrations.

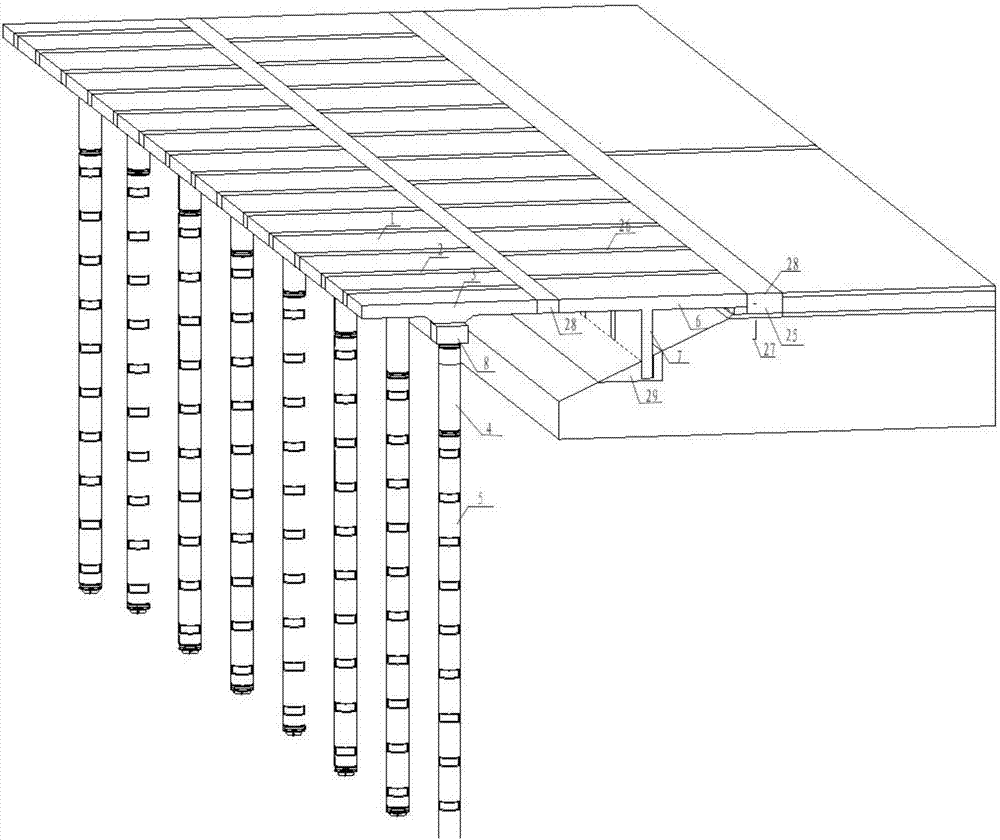

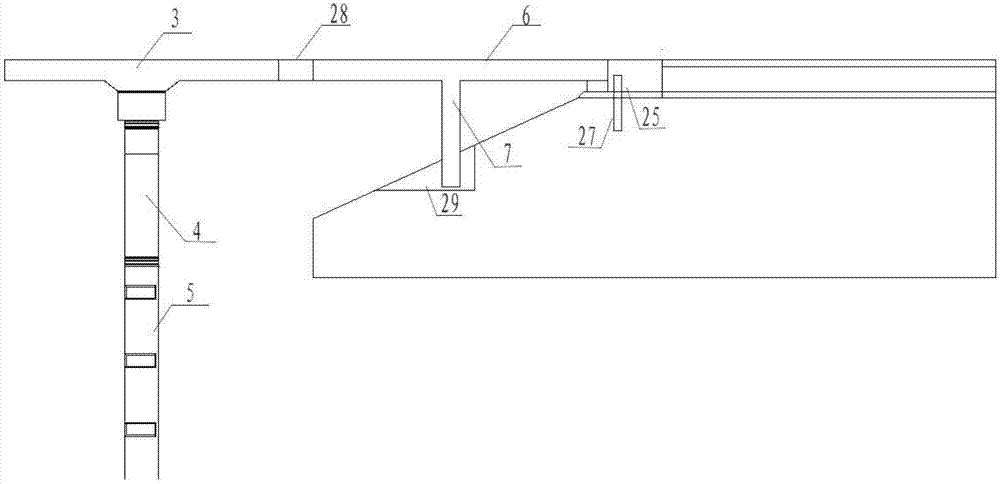

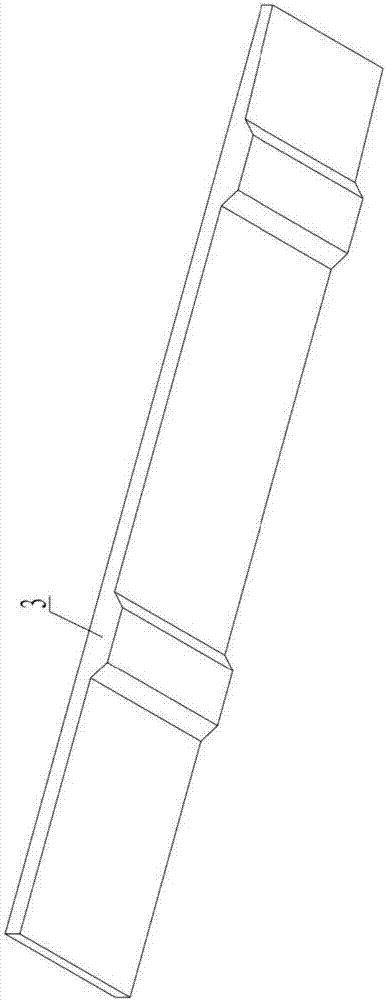

[0053] Such as Figure 1-11 As shown, a soilless roadbed of assembled wallboard and pile-board combined soilless roadbed, including prefabricated segmental board 1, first cast-in-place wet joint 2, pile-board structure longitudinal rib 3, PRC pipe pile 4, PHC Pipe pile 5, end cap beam 8, wall panel structure prefabricated panel 6, second pouring joint 26, wall panel structure prefabricated wall 7, third cast-in-place wet joint 28, transverse connection cast-in-place belt 25 and corrugated steel Guardrail column 27; the prefabricated segmental plates 1 are connected through the first cast-in-place wet joint 2, the longitudinal rib 3 of the pile plate structure is arranged on the lower side of the prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com