Combination bearing suitable for elevator disc tractor

A combined bearing and traction machine technology, applied in the direction of rotating bearings, bearings, shafts and bearings, etc., can solve the problems of dispersion, difficult to meet the requirements of axial load, and high bearing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

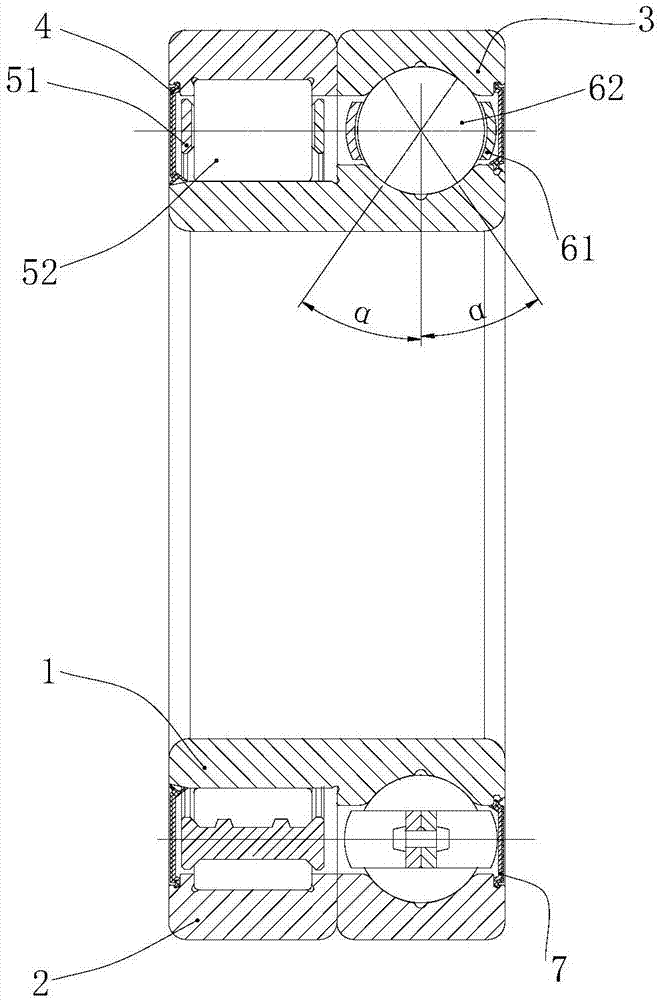

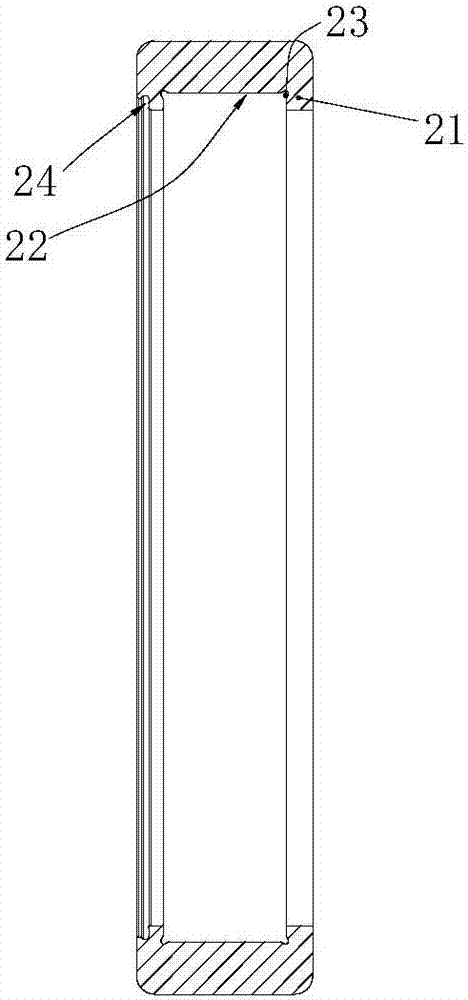

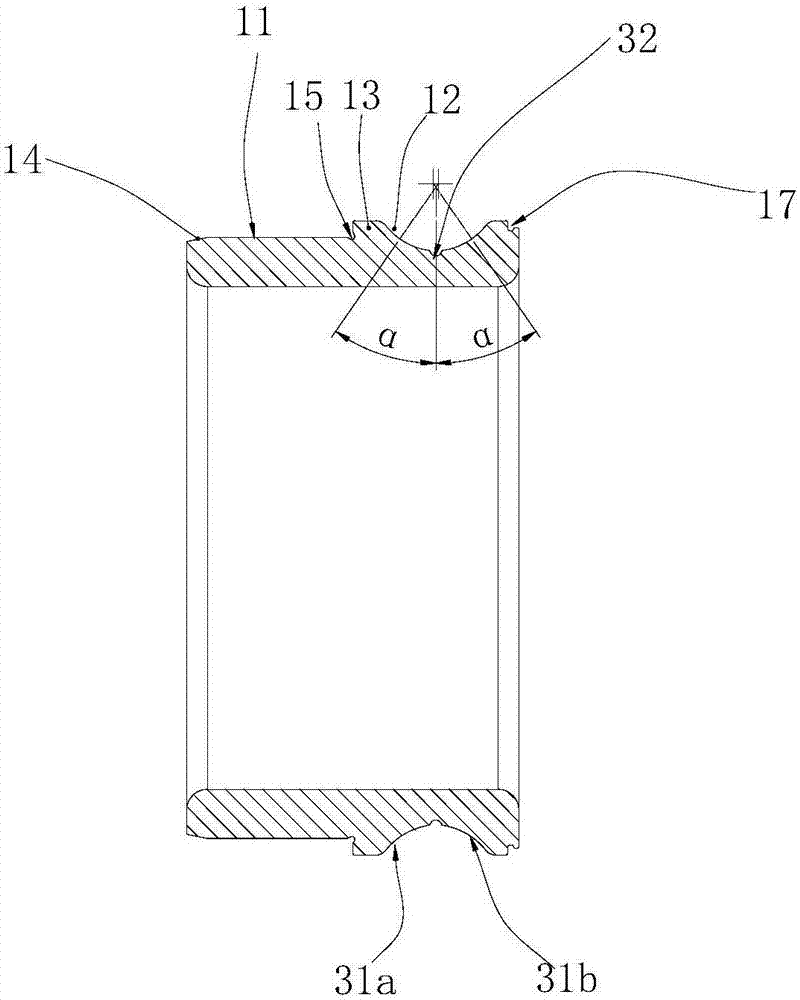

[0025] like Figures 1~8 The shown combined bearing suitable for an elevator dish-shaped hoisting machine includes a bearing inner ring 1 , and a first bearing outer ring 2 and a second bearing outer ring 3 positioned on the bearing inner ring 1 . The first bearing outer ring 2 and the second bearing outer ring 3 are arranged close to each other along the axial direction of the bearing inner ring 1 . The inner ring raceway surface 11 and the inner ring ball surface 12 are provided on the circumferential outer side wall surface of the inner ring 1 of the bearing, and the inner end of the inner ring ball surface 12 protrudes from the inner ring raceway surface 11 to form an inner ring retaining wall 13. A radial cylindrical roller assembly is installed between the first bearing outer ring 2 and the bearing inner ring 1 , and the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com