Electric melting joint and interface for high-pressure pipeline system and implementation method

A technology for electrofusion joints and high-pressure pipelines, applied in the direction of pipeline connection layout, pipe/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as erosion of fiber layer, failure, etc. to bearing capacity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

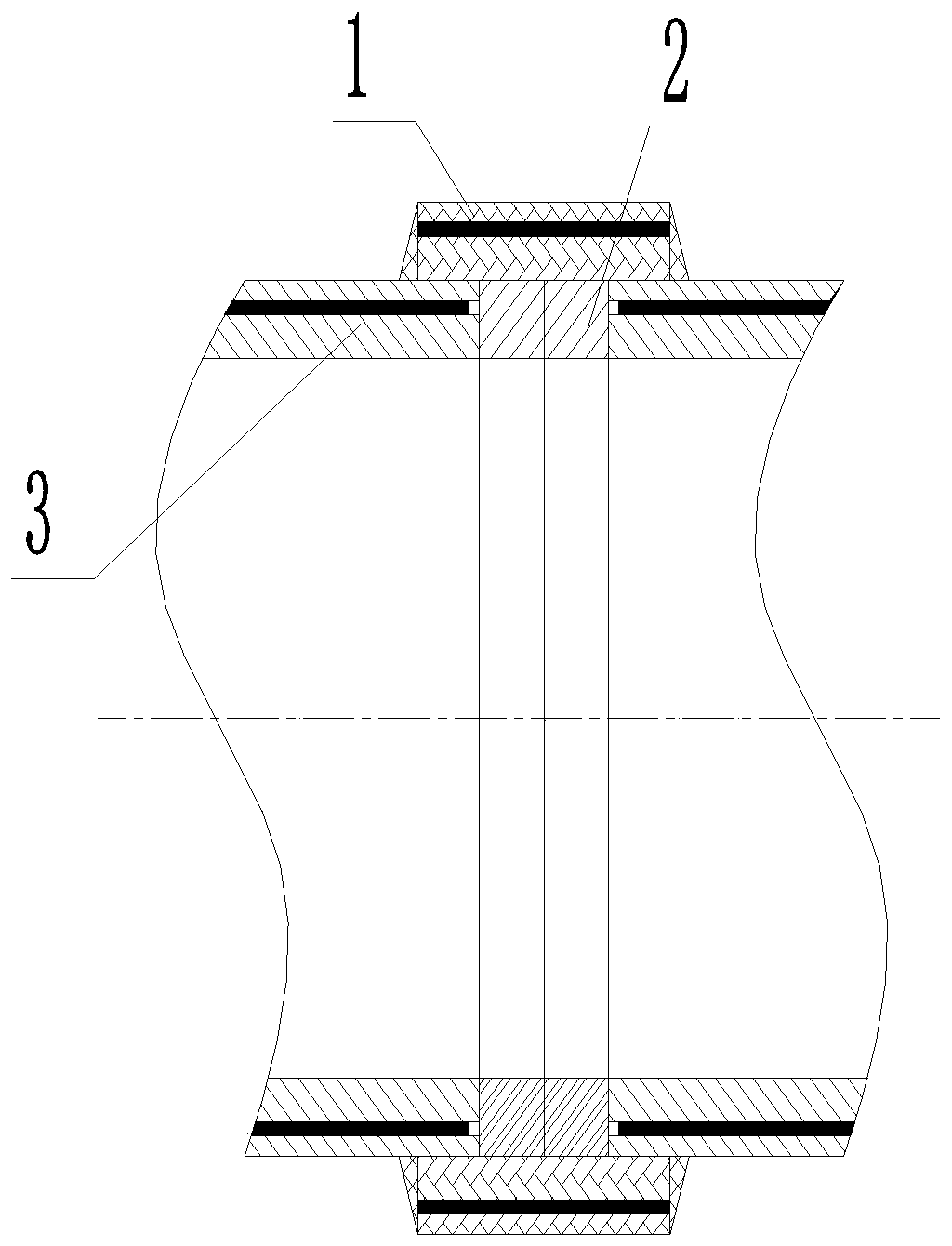

[0048] Such as figure 1 with figure 2 As shown, an electrofusion joint and interface for a high-pressure piping system. The electrofusion joint includes a thermoplastic continuous fiber core layer integrally laminated reinforced composite pipe with resistance wires laid on the inner wall. The electrofusion joint interface includes an electrofusion pipe sleeve 1 , Two short plastic pipes 2 and an external continuous fiber prepreg reinforced high-pressure composite pipe 3 connecting two short plastic pipes 2. The short plastic pipe 2 is fused with the electrofusion pipe sleeve 1 to form an anti-penetration sealing socket, and the continuous fiber is connected outside The outer wall of the prepreg reinforced high-pressure composite pipe 3 and the electric fusion pipe sleeve 1 are fused to form an anti-axial tensile and twisting socket.

[0049] Because the plastic layer of the outer tube of the external continuous fiber prepreg reinforced high-pressure composite pipe 3 is thin and t...

Embodiment 2

[0051] Such as figure 1 with image 3 As shown, the implementation method of the electrofusion joint and interface is as follows when used in the installation of new pipelines:

[0052] Step 1. Use a tapered cutter head cutter or a polishing machine to remove the fiber layer inside the outer wall of the external continuous fiber prepreg reinforced high-pressure composite pipe 3, and the removal depth is 10-30mm;

[0053] Step 1: Two plastic short tubes 2 of a certain length are fused and butt-connected with the corresponding ports of the external continuous fiber prepreg reinforced high-pressure composite tube 3 to form a butt joint;

[0054] Step 2: Use a polisher to remove the welded bumps on the inner and outer walls of the interface;

[0055] Step 3: Insert the electrofusion tube sleeve 1 from one end of the continuous fiber prepreg reinforced high-pressure composite tube 3 where the plastic short tube 2 is welded, and move the port of the electrofusion tube sleeve 1 and the plast...

Embodiment 3

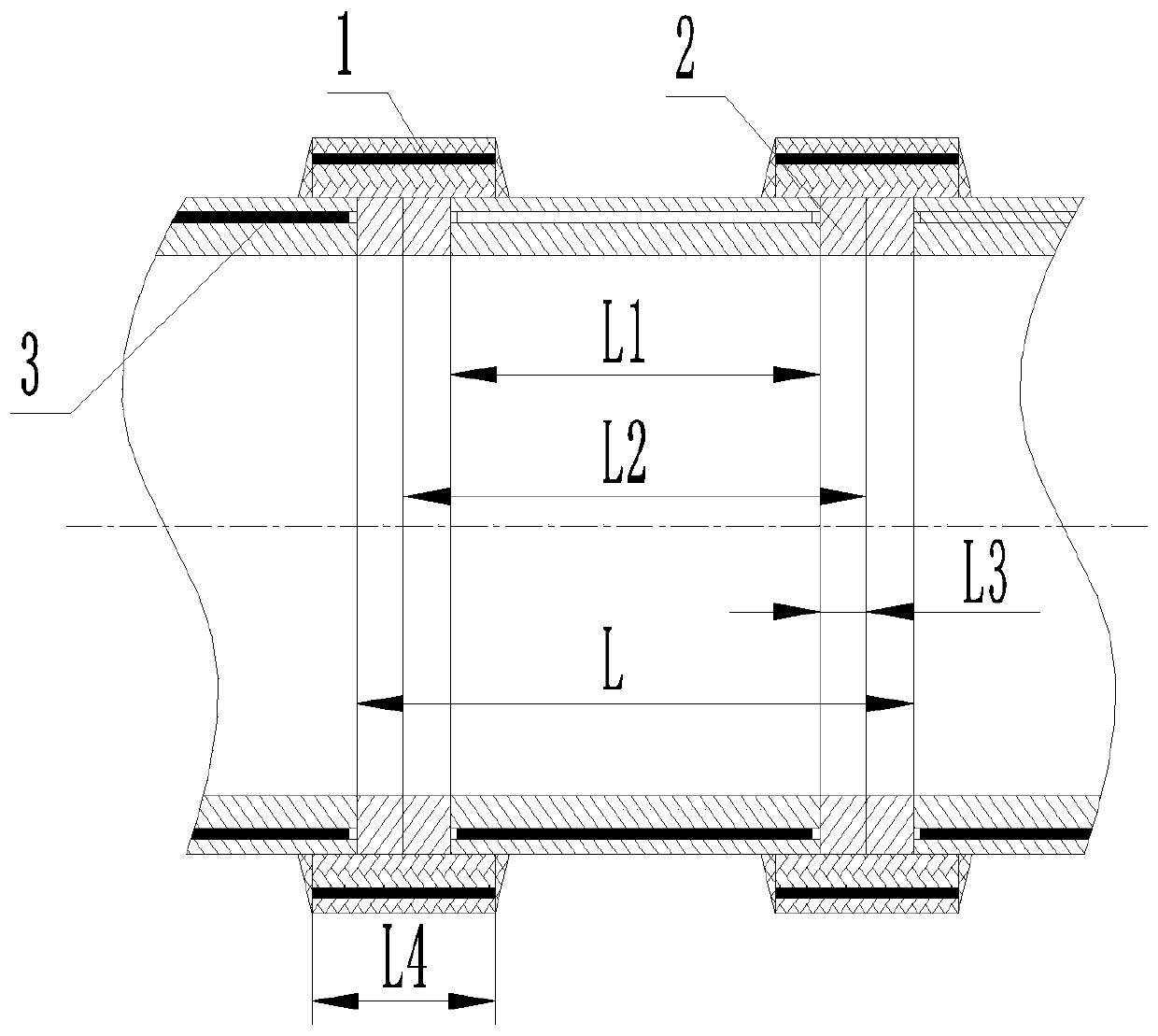

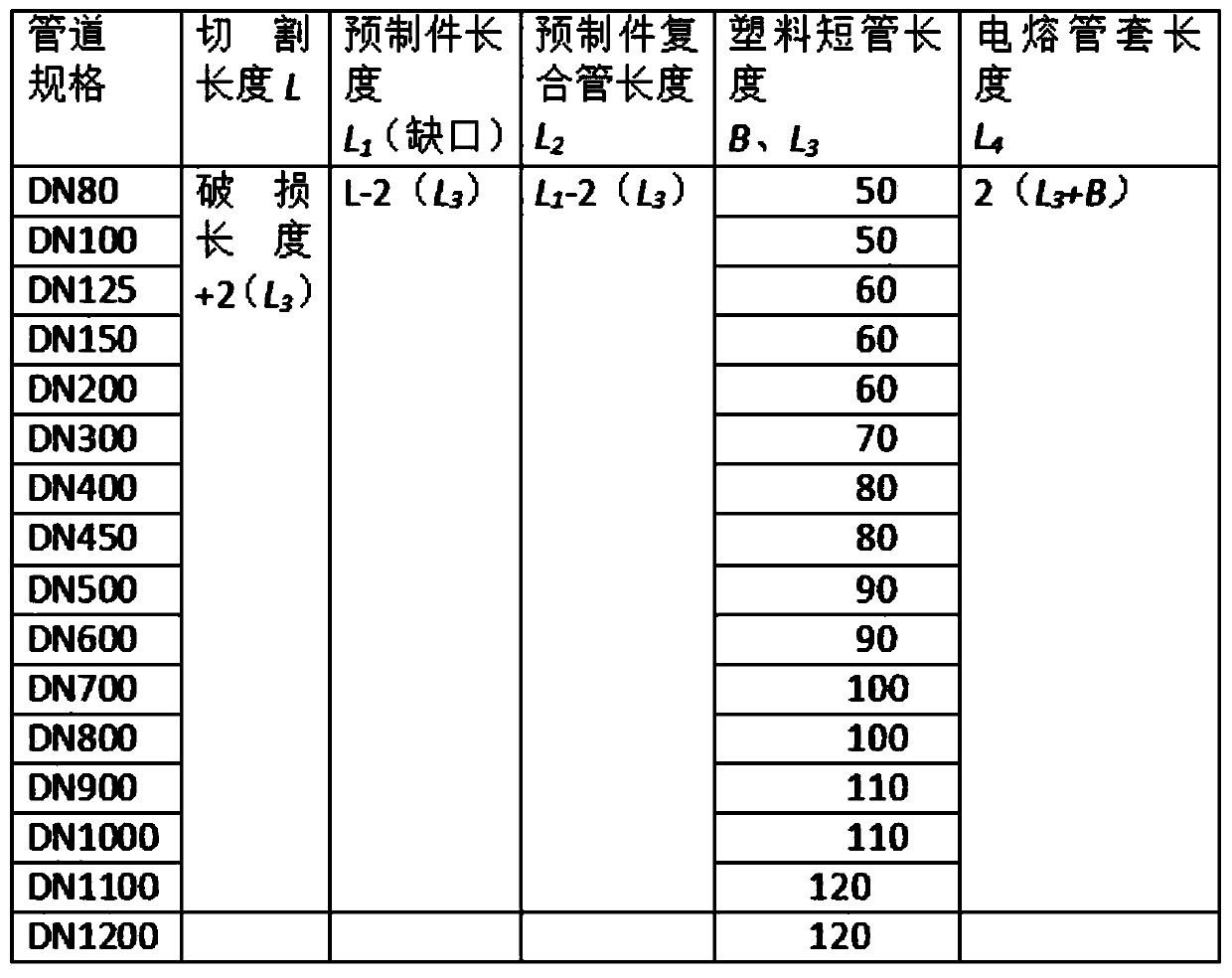

[0062] Such as figure 2 with image 3 As shown, the implementation method of the electrofusion joint and interface is used for quick repair of damaged pipelines as follows: L=damage length+2(L 3 ); L 1 =L-2(L 3 ); L 2 =L 1 -2(L 3 ); L 4 = 2(L 3 )+parameter (B); L: total length of pipe cutting; L 1 : Length of preform (notch); L 2 :Length of prefabricated composite pipe; L 3 :The length of short plastic pipe (tensile and shear length); L 4 : Length of electrofusion joint; B: Length of tensile and shear.

[0063] A1. According to the situation of the damaged pipe, close the nearby gate valve and drain the medium in the pipe in time;

[0064] A2, use a tape measure to measure the length of the damaged pipe + 2L 3 As cutting pipe length L, L 3 Is a short plastic tube 2;

[0065] A3. After using a tape measure circle as a support and marking the line with a marker pen, use a portable cutter to neatly cut along the marker line to form two pipe ports with a distance of L 2 ;

[0066] A4. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com