Bearing for centrifugal compressor, centrifugal compressor and air conditioning system

A technology for centrifugal compressors and air-conditioning systems, applied in the fields of centrifugal compressors, bearings for centrifugal compressors, and air-conditioning systems, can solve the problems of rising lubricating oil temperature, reduced bearing life, reduced lubrication effect, etc., so as to reduce the number of times and increase the number of bearings. Life, the effect of increasing the stiffness of the air film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

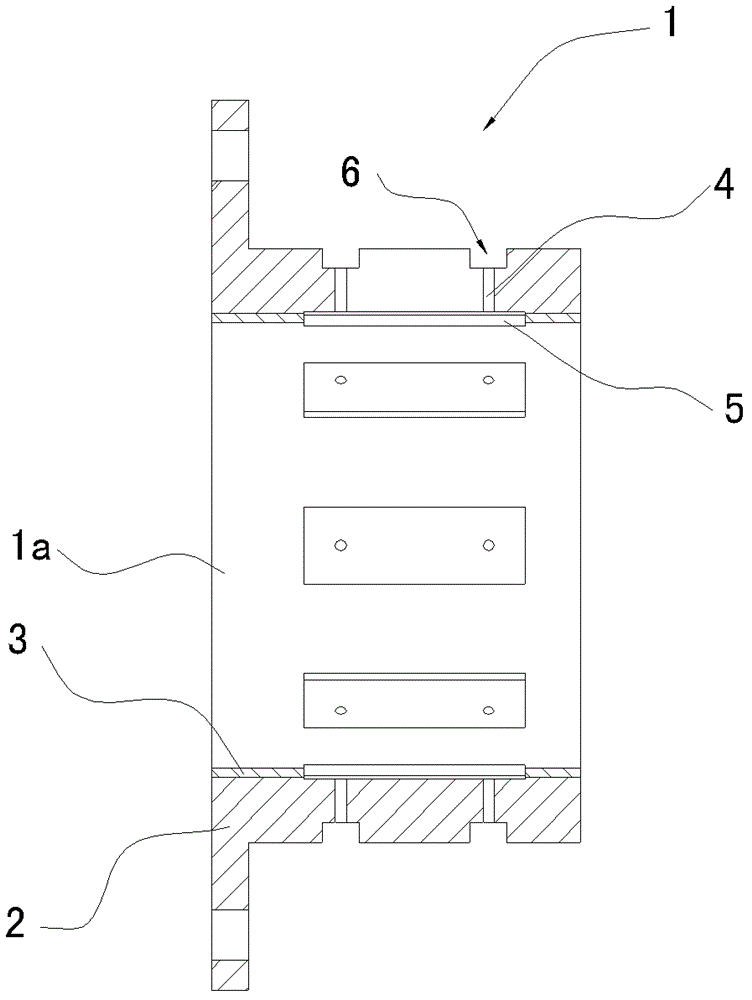

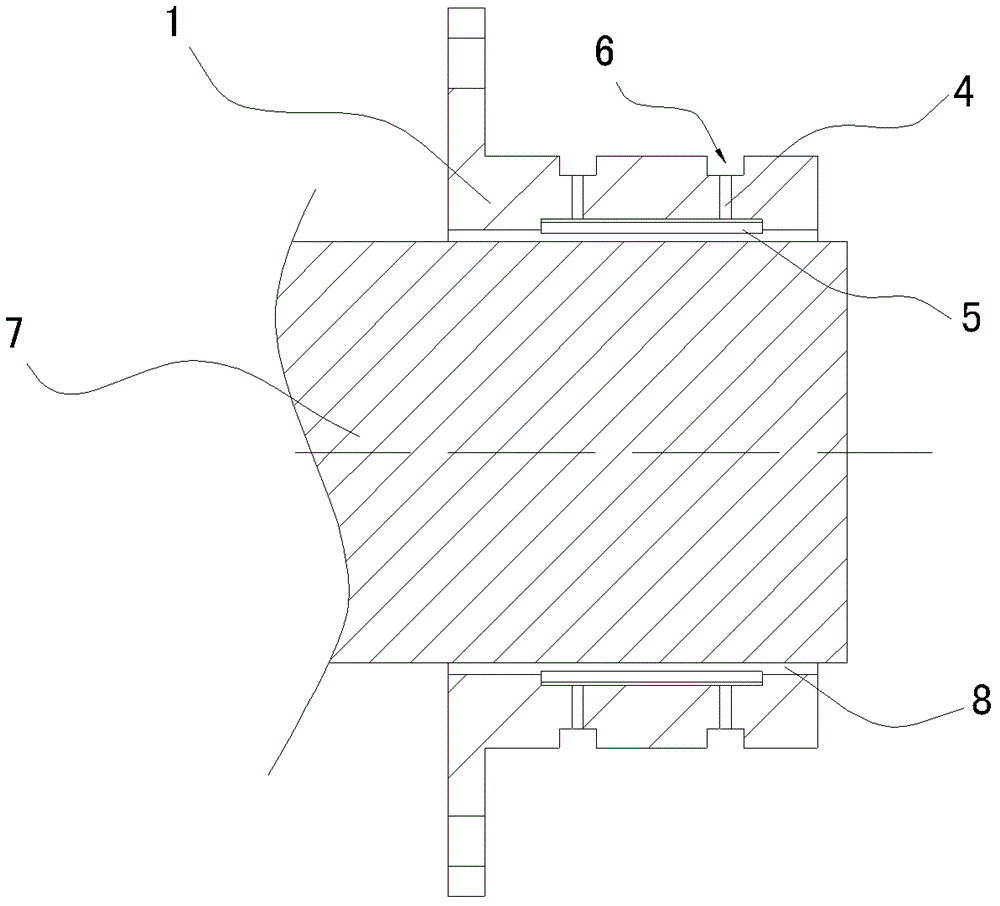

[0029] like figure 1 As shown, a bearing 1 for a centrifugal compressor includes a bearing bush 2 and a bearing bush 3 disposed on the inner surface of the bearing bush 2, and the material of the bearing bush 3 is engineering ceramic material. The center of the bearing 1 has a center hole 1a. The bearing 1 is processed with two rows (8 in each row) of radially penetrating air supply holes 4 arranged at equal intervals along the circumferential direction. On the inner wall of the bearing, eight air cavities 5 are arranged at equal intervals in the circumferential direction, and the air cavities 5 are rectangular grooves. It can be seen from the figure that the outlets of the eight air supply holes 4 in each row are respectively located in the eight air cavities 5 . Since the air supply holes 4 and the air cavities 5 are arranged at equal intervals along the bearing circumference, and the number of outlets of the air supply holes 4 in each air cavity 5 is the same, it can ensu...

Embodiment 2

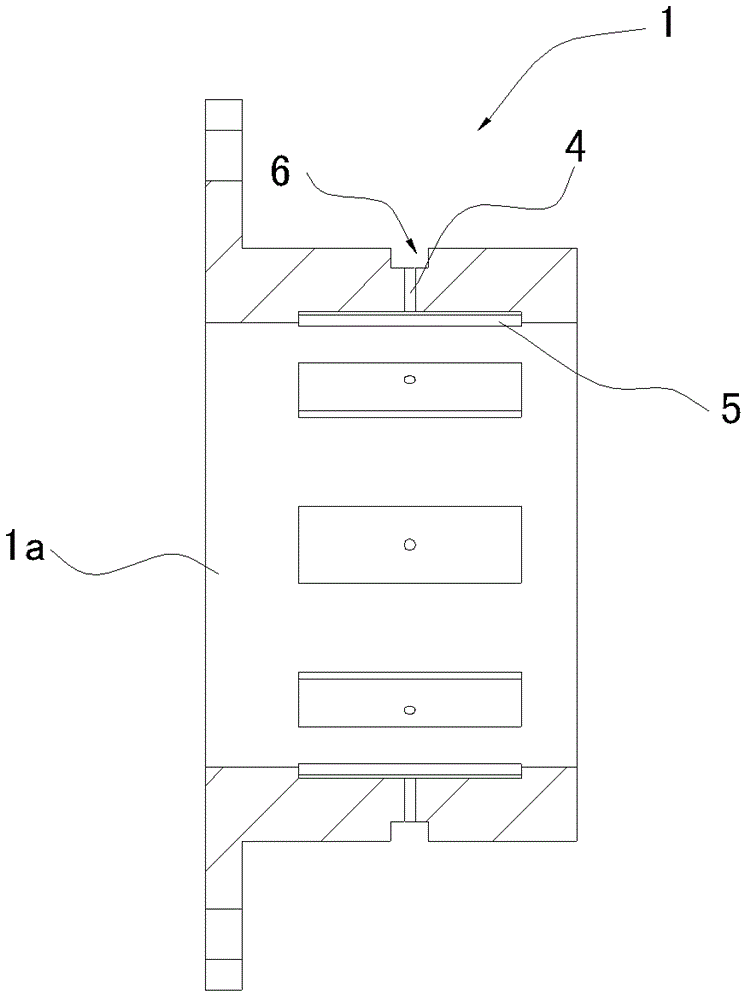

[0039] like image 3 As shown, the difference from Embodiment 1 is that a row of radially penetrating air supply holes 4 arranged at equal intervals in the circumferential direction is processed on the bearing 1 . Compared with the bearing in embodiment 1, the bearing in this embodiment has a simpler structure and is easier to process.

Embodiment 3

[0041] like Figure 4 As shown, the difference from Embodiment 1 is that three rows of radially penetrating air supply holes 4 arranged at equal intervals in the circumferential direction are processed on the bearing 1 . Compared with the bearing of Embodiment 1, the bearing of this embodiment can ensure a more uniform axial bearing capacity for the journal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com