A large-curvature spherical multi-layer split rubber-metal joint

A rubber-metal, large-curvature technology, applied in the direction of pivot connection, can solve the problems of poor dynamic performance and durability, no use of large-curvature spherical surface, small deflection and torsional stiffness, etc., to eliminate tensile stress and reduce deflection and torsional stiffness, reducing the effect of deflection and torsional stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

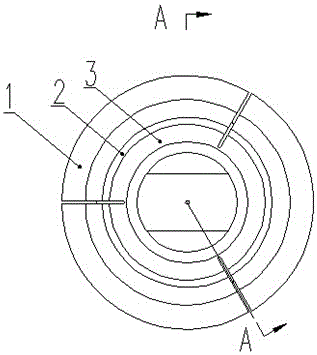

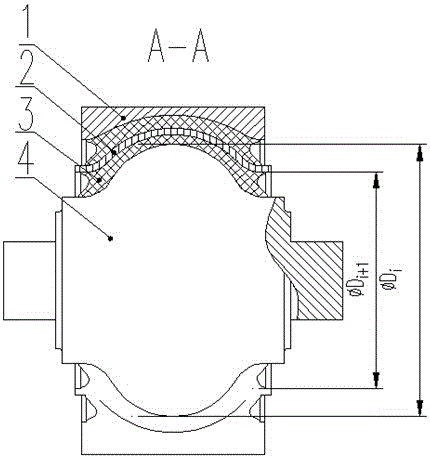

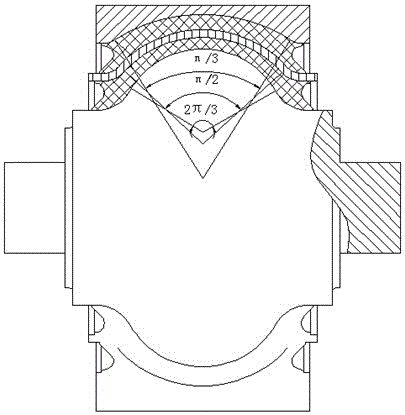

[0025] attached figure 2 and 3 A specific embodiment of the present invention is presented. It can be seen from the accompanying drawings that the present invention relates to a large-curvature spherical multi-layer split rubber-metal joint, which includes a metal jacket 1, a metal spacer 2, an elastic rubber body 3 and a metal mandrel 4; a metal jacket 1, a metal spacer The bonding surface between the sleeve 2 and the metal mandrel 4 and the elastic rubber body is a spherical surface with large curvature, the spherical radian of the metal jacket 1 is π / 3, the spherical radian of the metal spacer 2 is π / 2, and the spherical radian of the metal mandrel 4 is 2π / 3; The metal jacket 1 and the metal spacer 2 are divided into three parts before vulcanization; the elastic rubber body 3 and the metal jacket 1, the metal spacer 2 and the metal mandrel 4 are integrally vulcanized into one body. The rubber body is divided into two layers by the metal spacer 2; the metal jacket 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com