High-accuracy planetary reducer integrated with motor

A planetary reducer, high-precision technology, applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems that affect the processing period, increase the overall size, and the accuracy of the whole machine cannot be guaranteed, so as to achieve the guarantee of working performance and reduce The effect of form factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

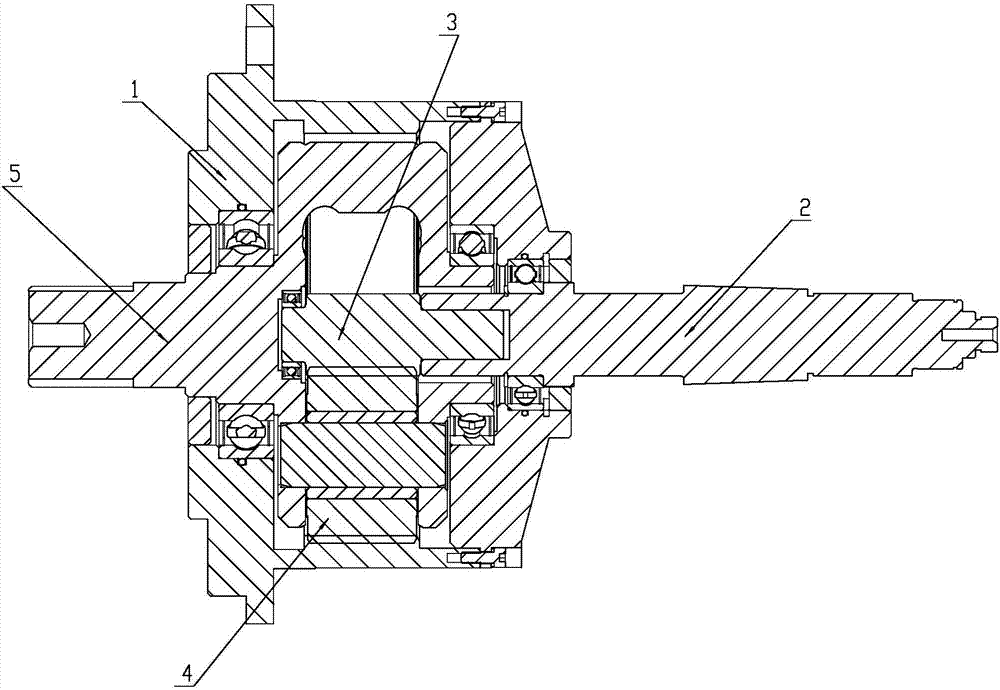

[0012] like figure 1 As shown, the high-precision planetary reducer integrated with the motor includes a double-supported planetary carrier 1, a motor rotor shaft 2, a sun gear 3, a planetary gear 4 and an output spline shaft 5, and the double-supported planetary carrier 1 is a rotatable structure , the inner side of the double-supported planetary carrier 1 is provided with a ring gear, the end of the motor rotor shaft 2 is in interference connection with the shaft of the sun gear 3, the planetary gear 4 is fixed on the double-supported planetary carrier 1, and the planetary gear 4 is connected to the sun gear 3 and the sun gear 3 respectively. The ring gears of the double-supported planetary carrier 1 are meshed, and the output spline shaft 5 is connected to the rear end of the double-supported planetary carrier 1 . The output spline shaft 5 and the double-sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com