Fireproof exhaust valve

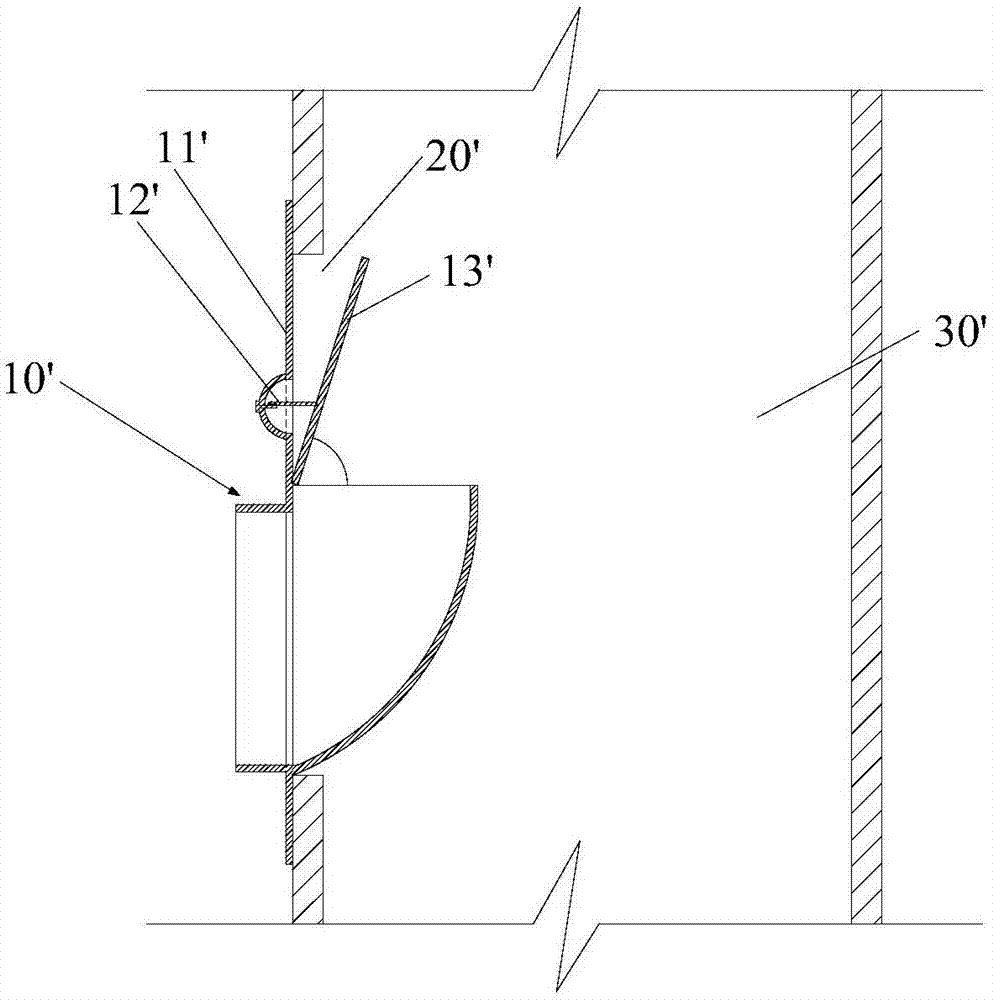

A technology for exhaust valves and air inlets, which is applied in the direction of safety valves, balance valves, valve devices, etc., and can solve the problem that the ceiling elevation of the room cannot be reached, the height of the fire-proof exhaust valve cannot be raised, and the maximum opening angle cannot be realized, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

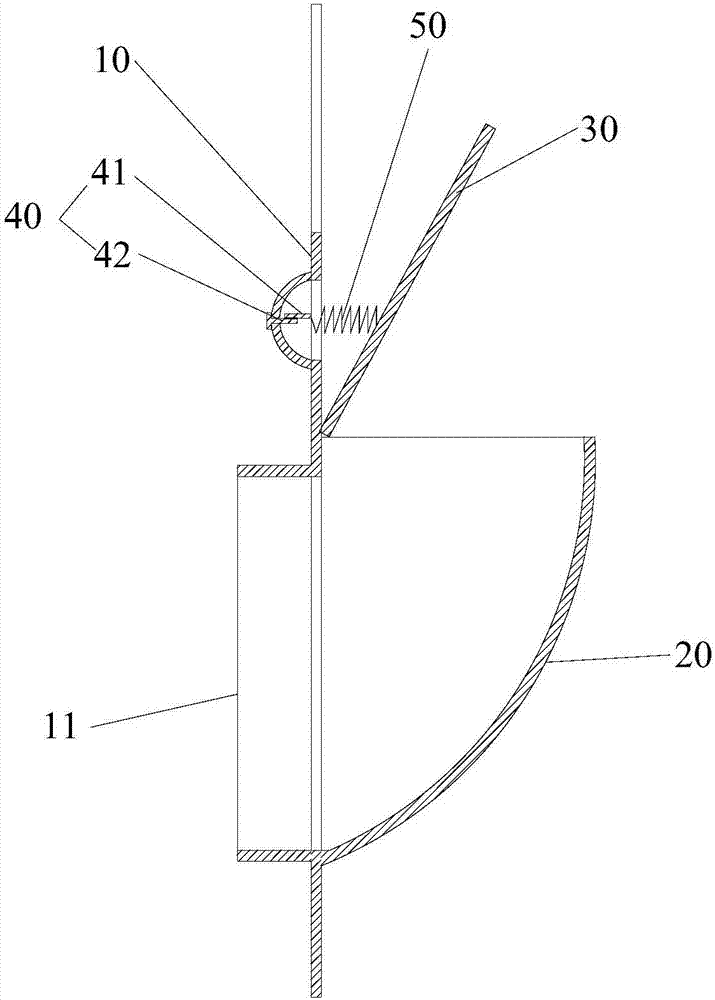

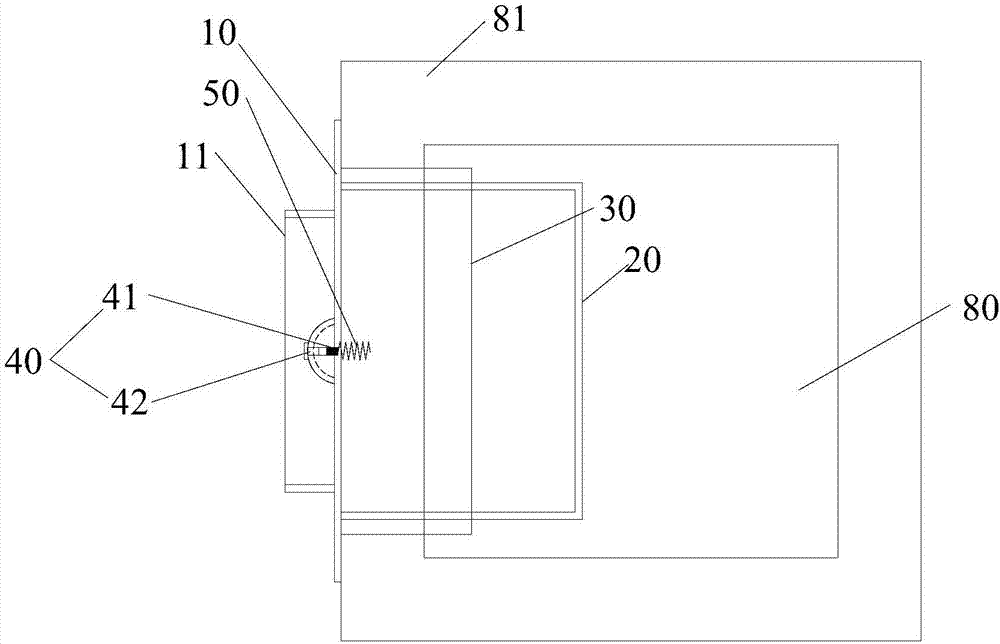

[0026] Reference Figure 2 to Figure 4 , The fire prevention exhaust valve provided by the first embodiment of the present invention includes a panel 10 provided with an air inlet 11, a guide pipe 20 arranged on one side of the panel 10 and communicating with the air inlet 11, and a fireproof exhaust valve arranged above the outlet of the guide pipe 20 The cover plate 30 and the fuse 40 arranged between the panel 10 and the fire cover plate 30. The fire exhaust valve also includes an elastic member 50 with spring performance for adjusting the angle between the fire cover plate 30 and the horizontal plane. One end of the piece 50 is connected to the movable end 41 of the fuse 40, the fixed end 42 of the fuse 40 is fixed on the panel 10, and the other end of the elastic piece 50 is connected to the fireproof cover 30.

[0027] In this embodiment, the elastic member 50 is a spring or an elastic piece.

[0028] by image 3 , Figure 4 It can be seen that a spring is provided between t...

Embodiment 2

[0030] Reference Figure 5 , Image 6 The difference between this embodiment and the first embodiment is that a normally closed non-return sheet 60 is also provided at the exit of the guide tube 20 and under the fire cover 30. When the exhaust fan is exhausting into the pipeline, the non-return flap 60 is opened and the gas is discharged into the pipeline through the outlet. When the exhaust fan stops exhausting into the pipeline, the non-return flap 60 will fall back to a normally closed state to prevent backflow of gas in the exhaust duct . The similarities between this embodiment and the first embodiment will not be repeated here.

Embodiment 3

[0032] Reference Figure 7 , Figure 8 In this embodiment, an enclosure 70 is added on the basis of the second embodiment. Specifically, the enclosing plate 70 is arranged on the outer side of the guide pipe 20, and its purpose is to use the principle of Berger’s equation to reduce the positive pressure of the air inlet 11 or even reach the negative pressure, which is beneficial to the gas discharge into the exhaust duct. The similarities between this embodiment and the third embodiment will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com