Chimney having automatic direction adjustment function

A technology of automatic adjustment and chimney, which is applied in the direction of combustion method, combustion product treatment, exhaust gas device, etc., to achieve the effect of complete combustion, accelerated flue gas emission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

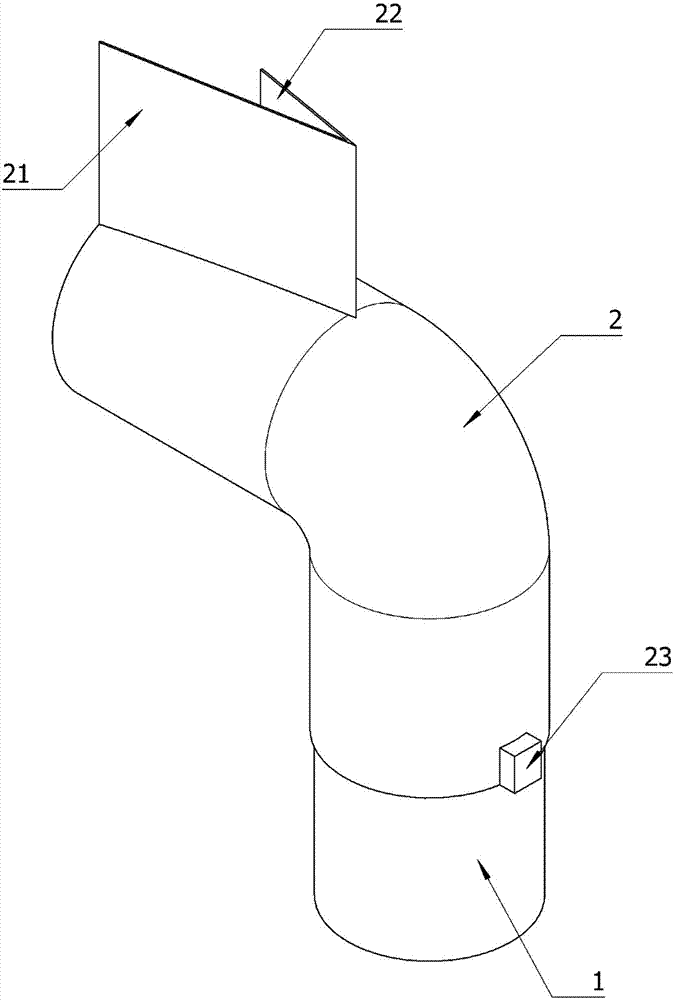

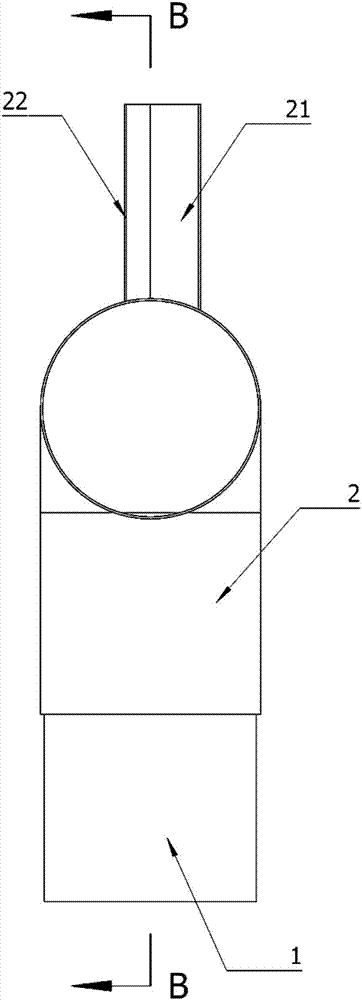

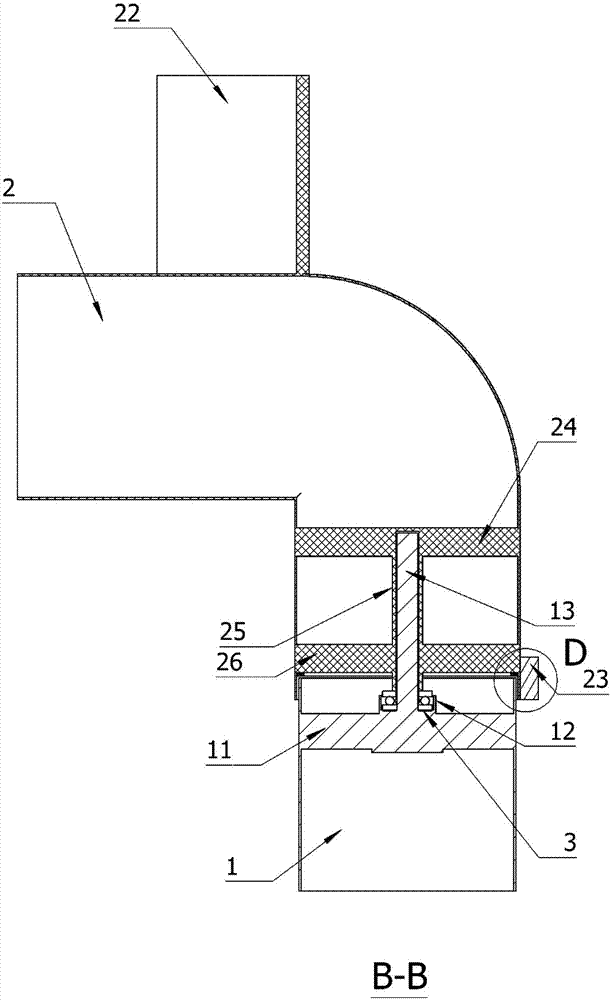

[0031] The structure of the chimney that automatically adjusts its direction is as Figure 1 to Figure 8 As shown, including: lower chimney 1, upper chimney 2;

[0032] see image 3 , Figure 5 , the inner wall of the lower chimney 1 is provided with several lower support rods 11, the upper part of the lower support rods 11 is provided with a bearing disc 12, which accommodates the plane thrust bearing 3, and a vertical shaft 13 placed vertically is arranged in the middle of the bearing disc 12. A smoke baffle 14 is set under the plate 12; the lower support rod 11 can fix the bearing plate 12, the vertical shaft 13, and the smoke baffle 14 on the inner wall of the lower chimney 1, and the smoke baffle 14 can prevent the hot smoke from directly impacting the bearing Disc, cooling can prolong the service life of the bearing.

[0033] see image 3 , Figure 6 , the upper chimney 2 is a bent pipe with a pipe diameter slightly larger than that of the lower chimney 1, so that a...

Embodiment 2

[0040] see Figure 8 , the basic scheme is the same as in Embodiment 1, the difference is that the large guide piece 21 of the upper chimney 2 is changed into a bent large piece 211, that is, the large guide piece 21 is bent from the middle, and the bending angle is 160 degrees. The purpose of bending is to make the windward areas of the large guide piece 21 and the small guide piece 22 equal, and the equal wind resistance on both sides can make the direction of the smoke outlet of the upper chimney 2 completely consistent with the wind direction, and obtain the greatest "wind pulling" effect. And before upper chimney 2 static balance, when chaotic wind blows to the middle of guiding small piece 22 and bending large piece 211, the wind resistance that bending big piece 211 suffers is bigger than flat plate, can accelerate the speed of turning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com