Ground cleaning machine vacuum degree detection system and detection method thereof

A detection system and detection method technology, applied in vacuum gauges, measuring devices, measuring fluid pressure, etc., can solve the problems of insufficient cleaning effect, sewage left on the ground, etc., and achieve the effect of high accuracy of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

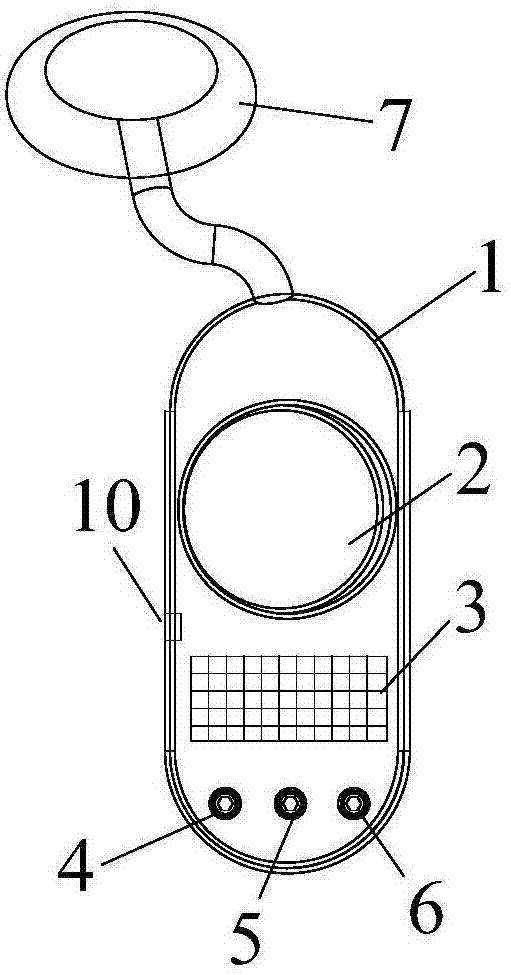

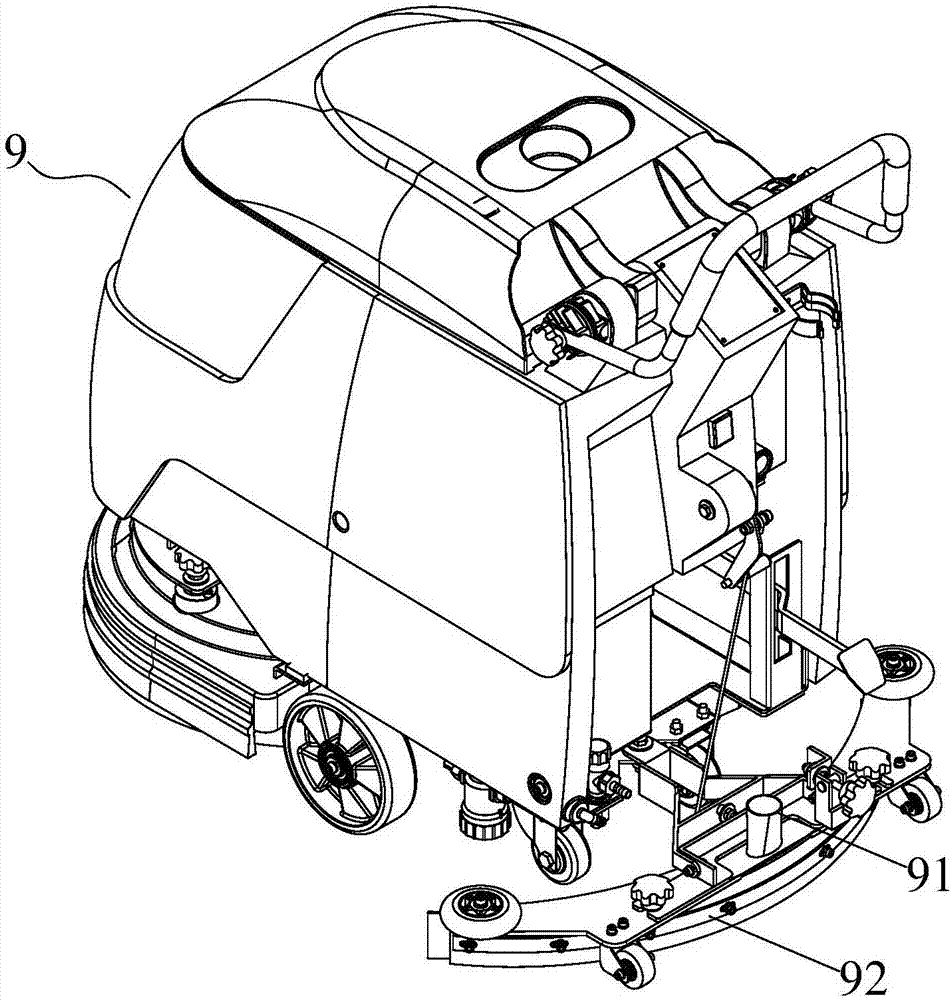

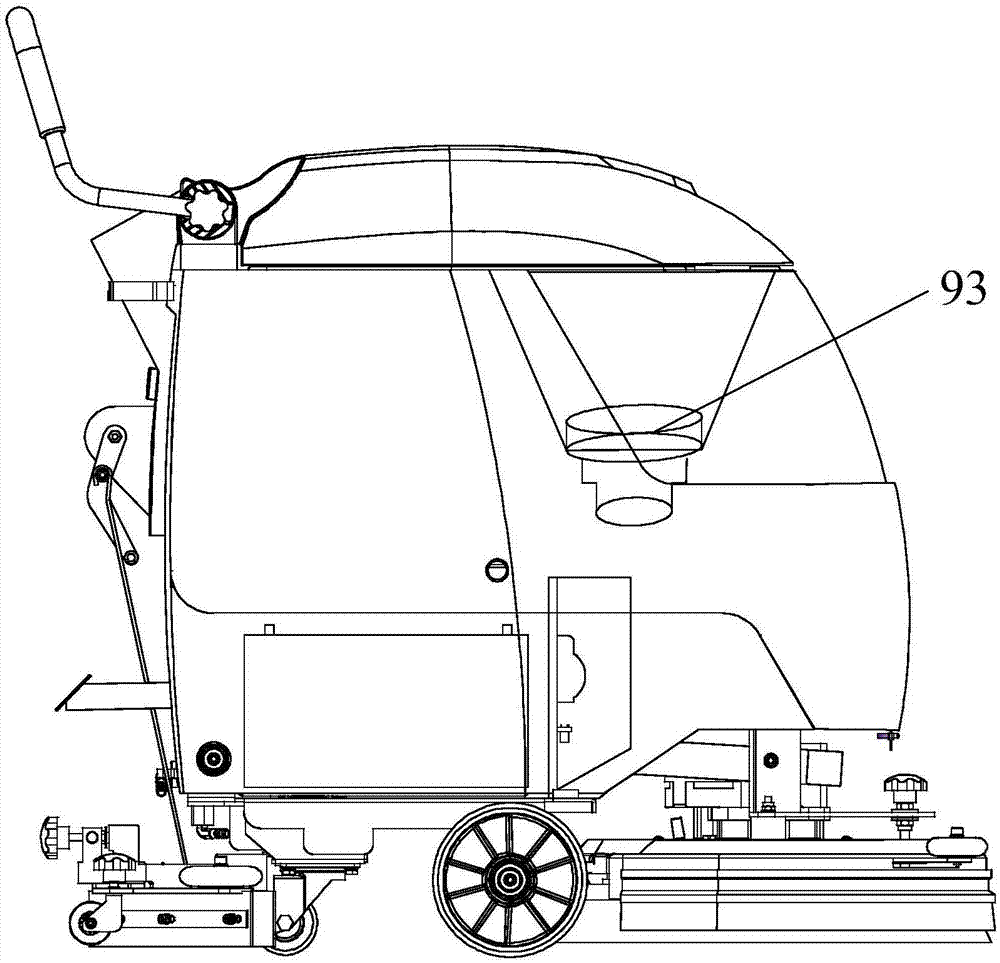

[0021] Such as Figure 1 to Figure 3 As shown, the present invention provides a vacuum detection system for a floor scrubber, including a controller, a human-computer interaction module connected to the controller, a vacuum pressure sensor and a storage module, the storage module is arranged on the human-computer interaction module, and the vacuum pressure The sensor is arranged at the sewage suction port of the floor washing machine, and the sewage suction port is connected with the waste water tank of the floor washing machine through the sewage suction pipe.

[0022] Specifically, as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com