Solar energy disc-type collection lens system and design method thereof

A concentrating mirror and solar energy technology, which is applied in the field of solar dish concentrating mirror systems, can solve the problems of large difficulty coefficient, high processing and manufacturing costs, and high difficulty in adjusting the gradient of light spot energy flow distribution, so as to reduce the number of manufacturing molds and reduce processing and manufacturing costs. , the effect of easy adjustment of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

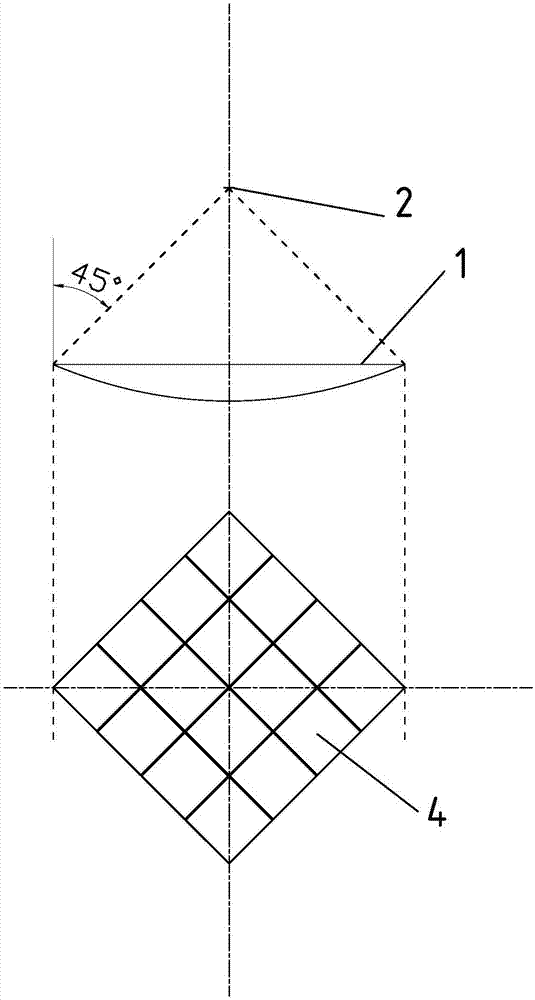

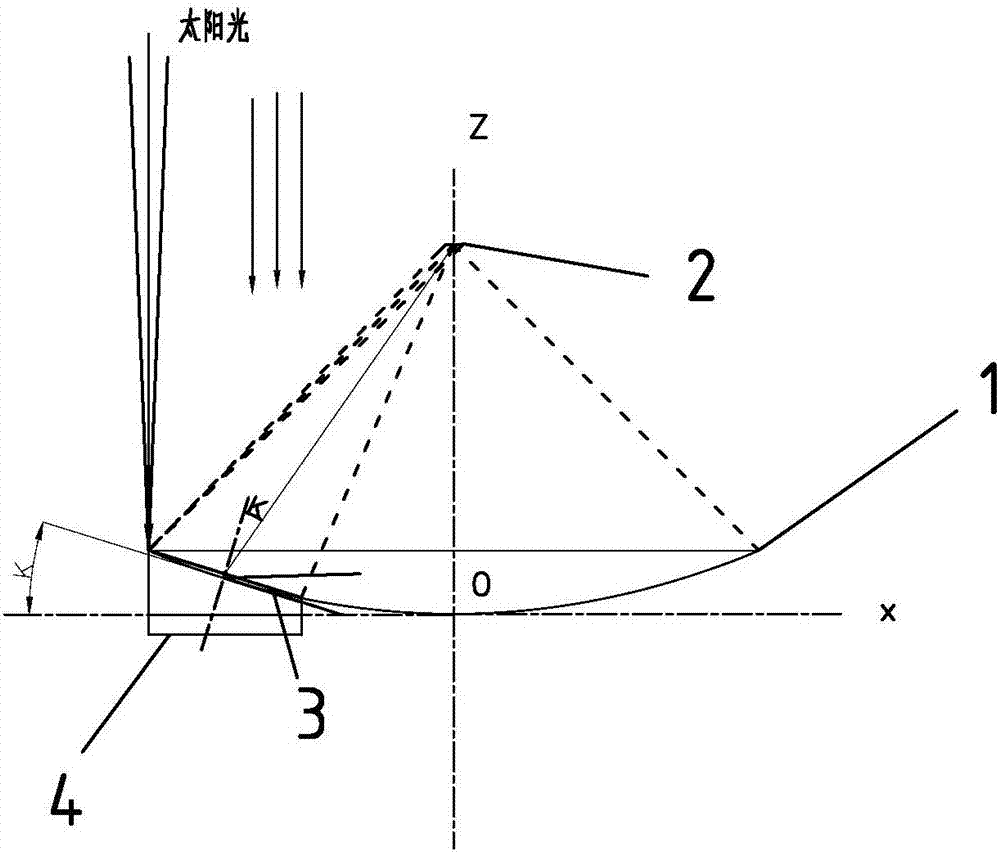

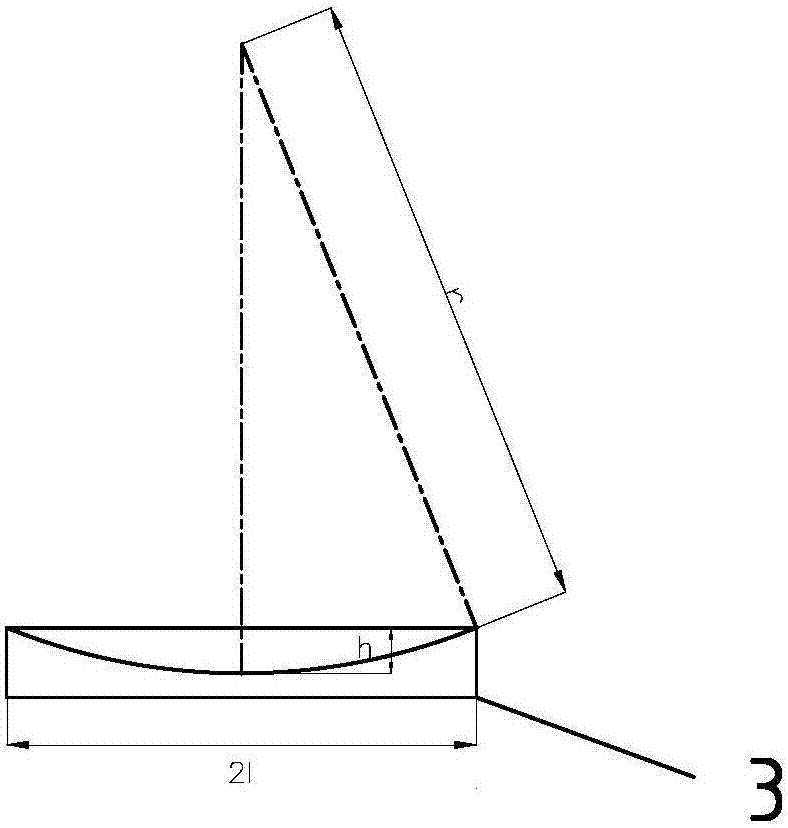

[0079] Such as Figure 1-Figure 3 As shown, a solar dish type condenser lens system includes a solar dish type condenser lens 1 and a heat absorber 2 located near the focal plane of the solar dish type condenser lens 1. The solar dish type condenser lens 1 is spliced by M spherical mirrors 3 The reflecting surface of the spherical mirror 3 is a quadrilateral curved surface, the four vertices of the quadrilateral curved surface are located on the same paraboloid of revolution, and the orthographic projections of the M spherical mirrors 3 on the tangent plane passing through the vertices of the paraboloid of revolution are all squares. And the area is equal.

[0080] The orthographic projection of the spherical mirror 3 on the tangent plane passing through the vertices of the spherical mirror 3 is quadrilateral, that is, the orthographic projection of the splicing line between a certain spherical mirror 3 and its adjacent spherical mirror 3 on the tangent plane passing the vertic...

Embodiment 2

[0112] A method for designing a solar dish type condenser lens system has the following steps:

[0113] 1) Calculate S, the S satisfies the following relationship:

[0114] W=DNI*S*μ*a 1 *a 2 *a 3 ,

[0115] Where, S is the equivalent area of the sum of the areas of M of the squares 4, m 2 ;

[0116] W is the rated power of the solar dish condenser 1, W, in this embodiment, W=6000W;

[0117] μ is the light interception efficiency of the solar dish type condenser lens 1, since α=45°, the solar dish type condenser lens 1 has the maximum light interception efficiency, μ=0.9;

[0118] DNI is the direct solar constant, W / m 2 , DNI=900W / m 2 ;

[0119] a 1 Is the reflectivity of the spherical mirror 3, a 1 =0.93;

[0120] a 2 Is the conversion efficiency of heat sink 2, a 2 = 0.4 (determined by heat sink 2, such as about 15% of monocrystalline silicon in photovoltaic solar panels);

[0121] a 3 Is the atmospheric absorption coefficient (air takes away the heat near the focal plane during the foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com