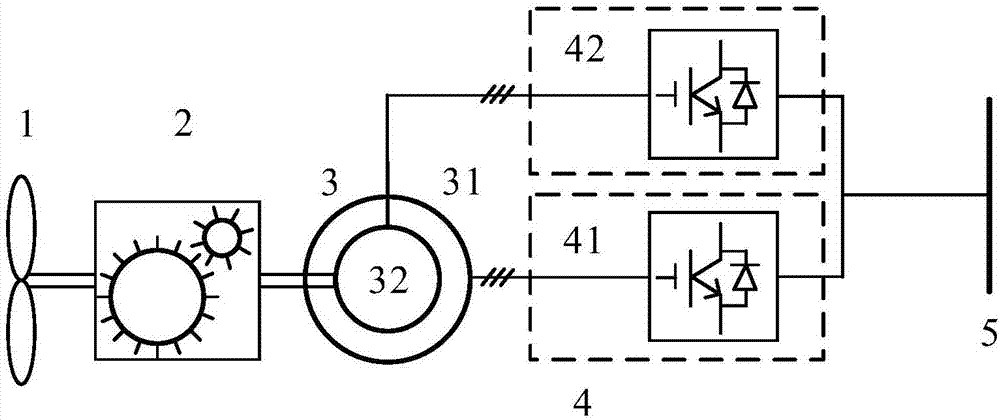

Low-speed gearbox and double-fed wind turbine optimization design method based on direct-current transmission

A technology of wind turbines and direct current transmission, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as rotor current increase, gearbox speed increase ratio reduction, gearbox volume, cost increase, etc., to achieve Effects of volume reduction, failure rate reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

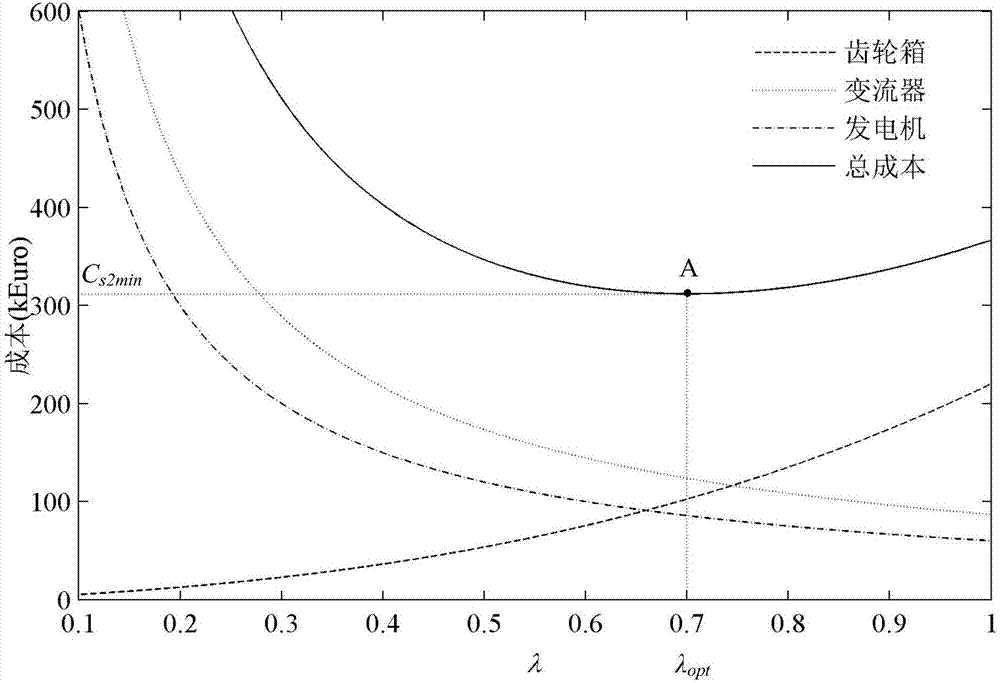

[0110] Taking the doubly-fed wind turbine produced by a certain company as an example, its main parameters are: P=3MW, V s =1650V (stator voltage), I s =600A, I r =608A,n 1N =1000rpm, n p =3, gearbox speed-up ratio N=80, L m =99mH,L s =99.99mH; gearbox cost C g1 = 220,000 Euros (Euro), DFIG cost C t1 = 60,000 Euros, converter cost C c1 = 86,700 euros, the total cost of the three parties C s1 = 366,700 euros; k 0 = 0,k 1 =0.2,k 2 =0.35,k 3 =0.45, β=1.01, α=0.0884.

[0111] First, draw the optimized gearbox cost C according to formula (18), formula (20), formula (22) and formula (6) g2 -λ curve, DFIG cost C t2 -λ curve, DC converter cost C c2 -λ curve, the total cost C of the above three in the doubly-fed wind turbine s2 -λ curves, such as figure 2 shown. from figure 2 As can be seen in , the cost of the gearbox C g2 Gradually decreases as λ decreases; the cost of the converter and DFIG (C c2 、C t2 ) gradually increases with the decrease of λ; the total c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com