Rotor position detection device of four-phase switched reluctance motor

A technology of rotor position detection and reluctance motor, which is applied in the direction of electronic commutator, etc., can solve the problems of increasing the difficulty of fault judgment, increasing sensor faults, and increasing hardware costs, so as to reduce the probability of sensor faults, reduce the difficulty of judgment, and reduce Effect of hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

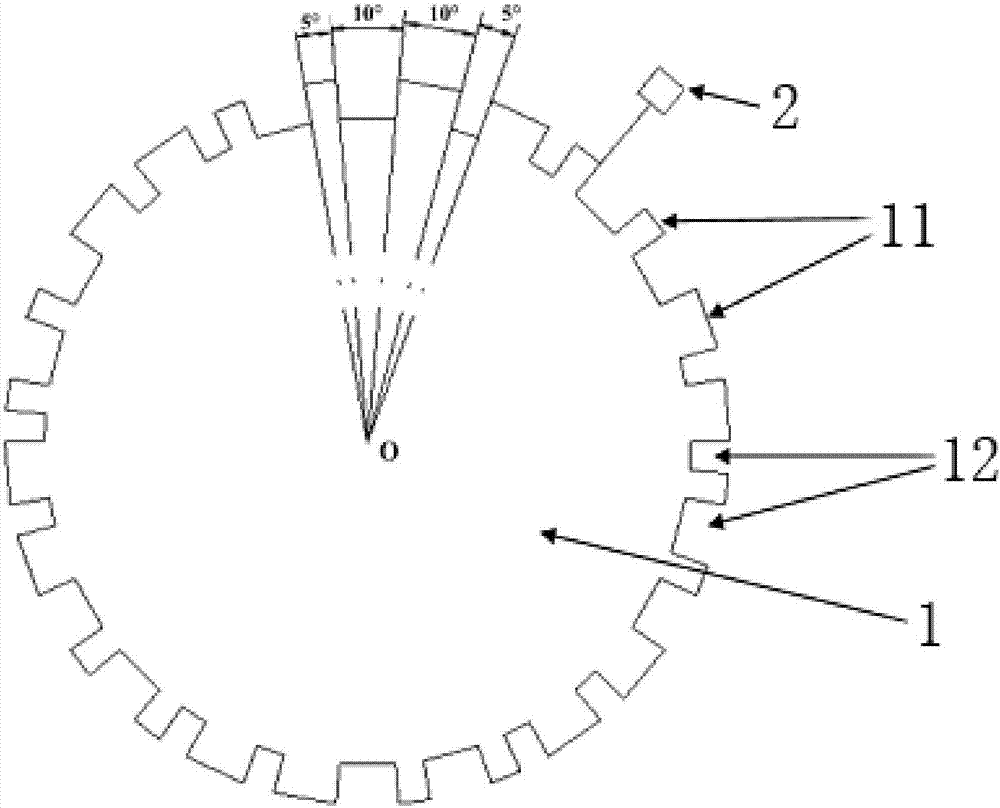

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

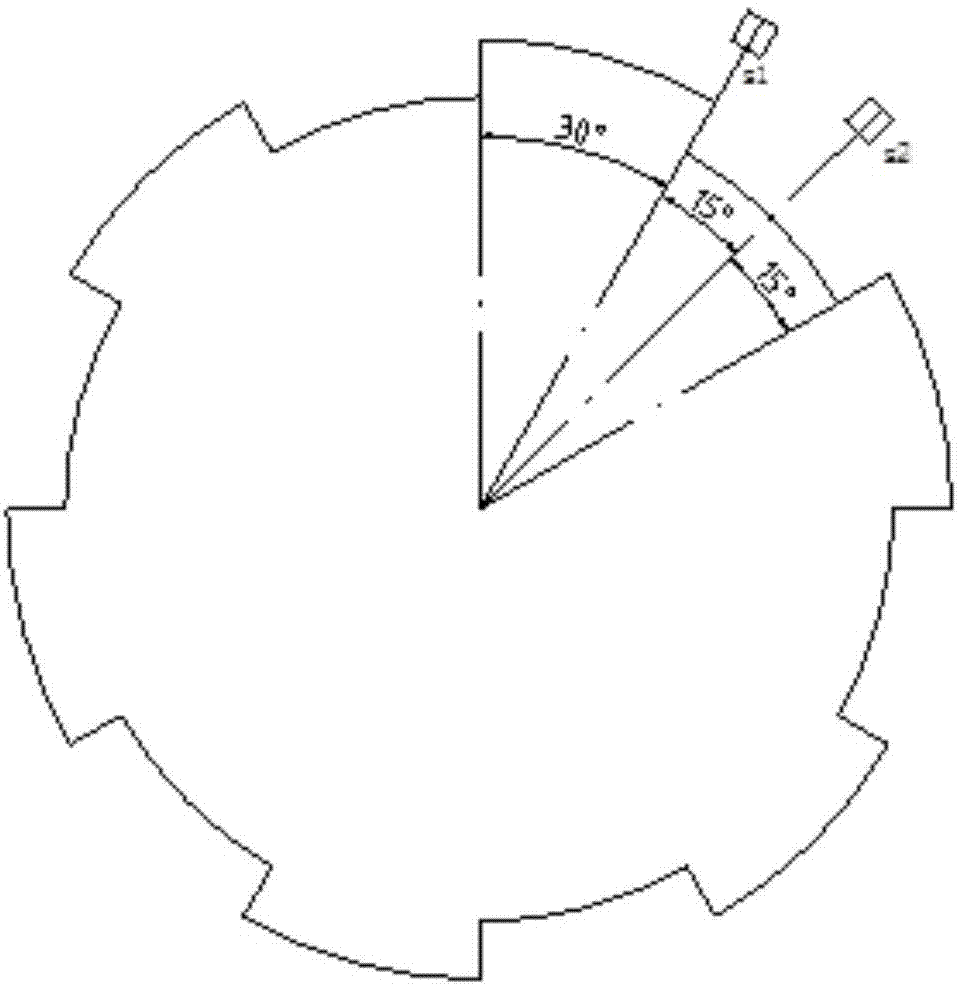

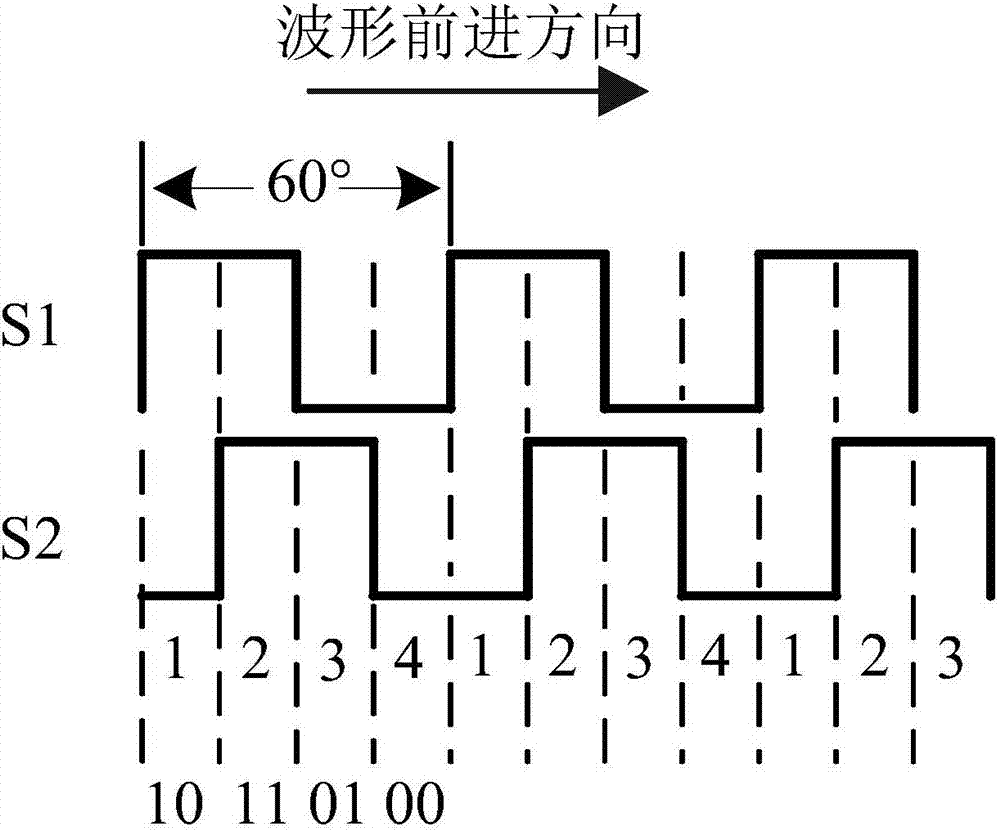

[0027] Figure 3 to Figure 11 Shown is the structural representation of the present invention.

[0028] Wherein the reference numerals are: code disc 1, convex detection part 11, concave detection part 12, detection sensor 2, sensor signal encoding module 3, encoding signal processing module 4, start processing module 41, calculation processing module 42, the first A memory 43 , a second memory 44 , and a phase output logic module 5 .

[0029] A rotor position detection device of a four-phase switched reluctance motor of the present invention uses a detection sensor 2 to detect the position signal of the code disc 1, and encodes the output signal, so that the position information of the motor rotor can be obtained, And it can improve the fault tolerance of the detection sensor 2 and improve the ability to judge the fault of the detection sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com