Efficiency soilless cultivation method

A cultivation method and high-efficiency technology, applied in the field of high-efficiency soilless cultivation, can solve problems such as difficult uniformity of light and water supply, inconsistent crop growth, and low work efficiency, so as to achieve uniform light and water supply and ensure growth The effect of consistent condition and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

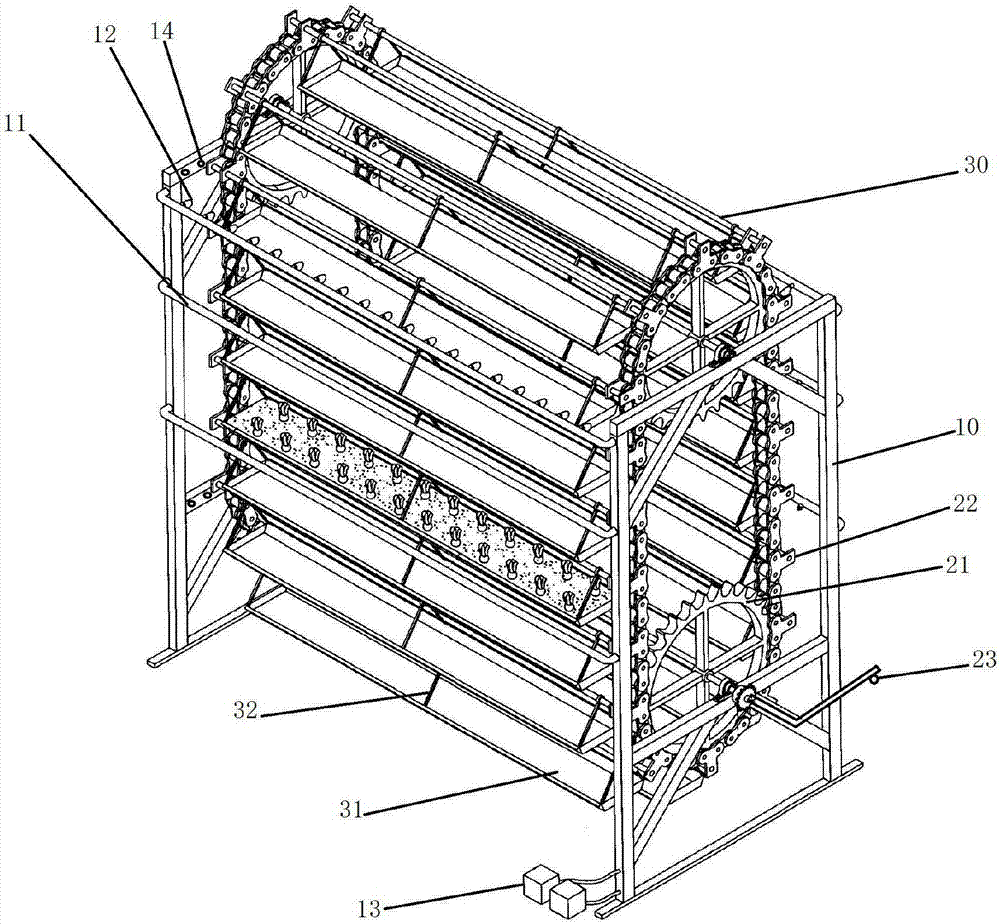

[0016] As shown in the figure, the soilless cultivation planting device adopted in the present invention includes a bracket body, and the bracket body includes two supporting frames 10 oppositely arranged. The supporting frames 10 are spliced by hollow stainless steel pipes, and the supporting frames 10 Connected by a plurality of conveying pipes 11 parallel to each other, each support frame 10 is provided with a group of cyclic power devices, the cyclic power device includes two sprockets 21, and the sprockets 21 are connected by a chain 22, and one of them The sprocket 21 is driven to rotate by the driving device; the two chains 22 on the two support frames 10 are connected together by a plurality of connecting rods 30 distributed on the chains 22 along the length direction of the chains 22, and the connecting rods 30 are hung There is a loading tray 31 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com