Aluminum pipe online secondary cleaning device

A secondary cleaning and cleaning device technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unclean outer surface, affecting the quality of aluminum tubes, and poor circulation, so as to avoid rough Crystal and fusing, convenient and quick disassembly and cleaning, and the effect of preventing cleaning agent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

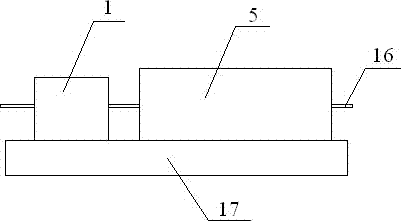

[0019] An on-line secondary cleaning device for aluminum tubes, the structure of which is as follows figure 1 As shown, it includes a sump 17, a first cleaning device 1 and a second cleaning device 5. The first cleaning device 1 and the second cleaning device 5 are arranged above the sump via a bracket. Among them, the first cleaning device 1 is used to clean stains on the surface of the aluminum pipe to complete the first cleaning operation; the second cleaning device 5 is used to remove the black lines on the surface of the aluminum pipe to complete the second cleaning operation; Collect the used cleaning agent for easy recycling and reuse.

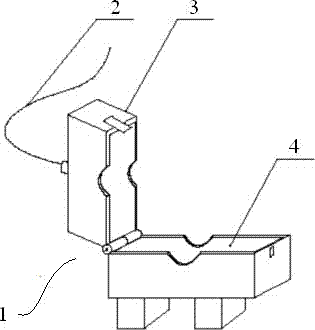

[0020] The structure of the first cleaning device 1 is figure 2 As shown, the housing 3 is buckled up and down and fixedly connected by a locking buckle. The left and right side walls of the housing are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com