Board cutting machine with movable saw cutter

A cutting machine and saw blade technology, applied in metal sawing equipment, sawing machine devices, metal processing machinery parts, etc., can solve problems such as waste, plate deviation, and products that cannot meet the needs, so as to reduce cutting errors and ensure cutting. Accuracy and the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

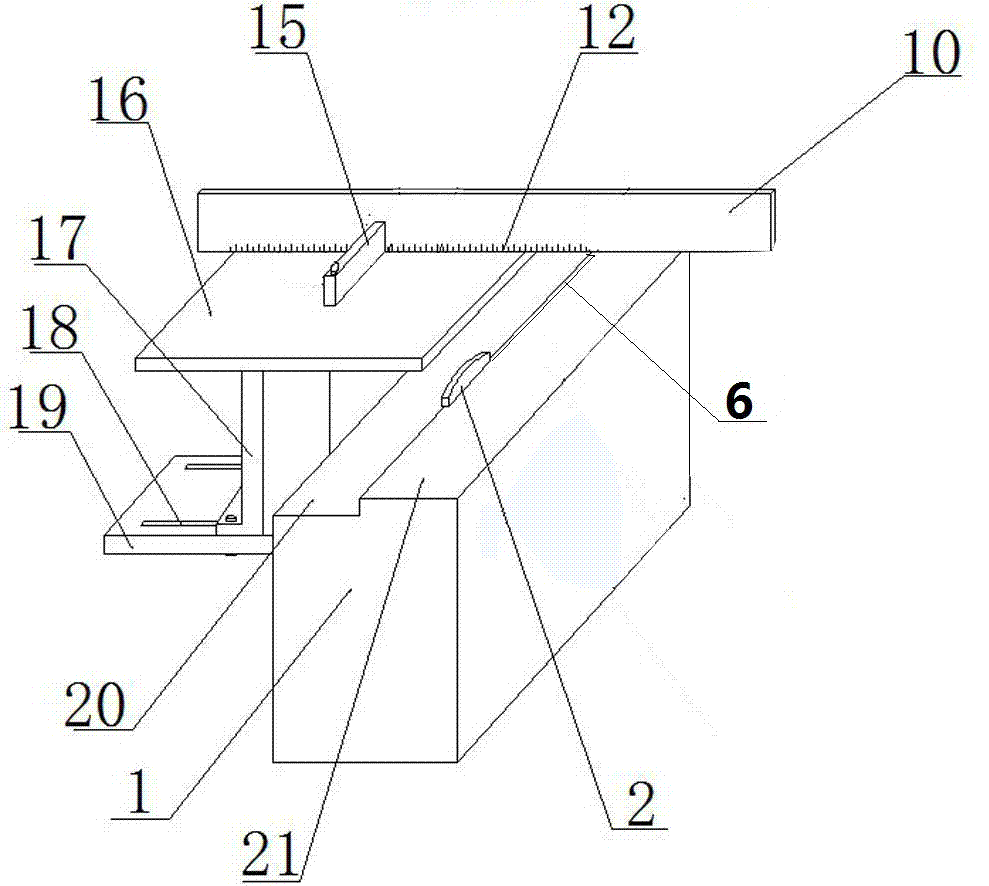

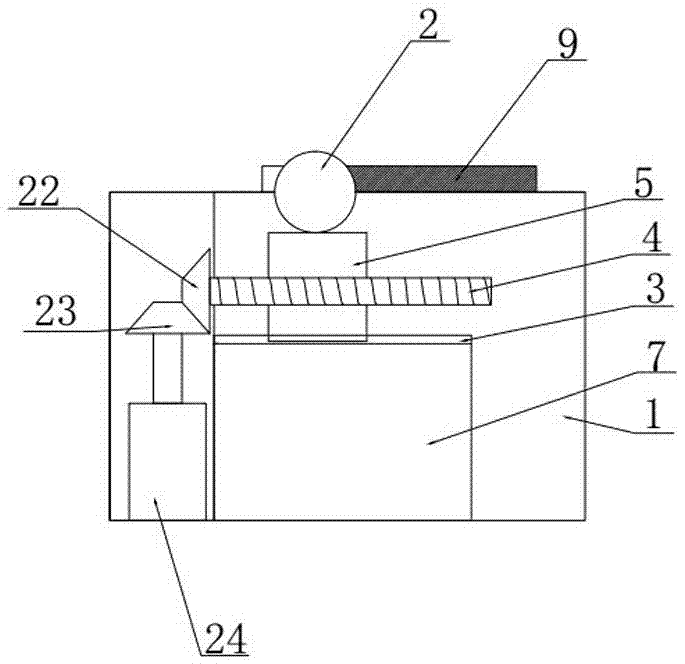

[0016] Embodiment 1: A board cutting machine with a movable saw blade includes a body 1, a workbench 21 and a sliding groove 20 are fixedly connected to the body 1, and a saw blade 2 and a sliding groove 20 are connected to the workbench 21 in rotation on one side relative to the sliding groove 20. Slot 6, slide groove 20 are respectively arranged parallel to saw blade 2 and workbench 21, slide groove 20 is provided with fixed platform 16, is provided with positioning plate 15 on fixed platform 16, and described fixed platform 16 below is provided with body 1 The support plate 19 that can be slidably connected, the support plate 19 is slidably provided with a connection plate 17, the upper end of the connection plate 17 is fixedly connected with the fixed table 16, and the support plate 19 is provided with a length of 25cm rectangular slot 18, the support plate 19 Connect with the connection plate 17 through the rectangular through groove 18 by bolts, the metering plate 10 is a...

Embodiment 2

[0017] Embodiment 2: It is basically similar to Embodiment 1, except that: the range of the scale 12 is 45 cm, and the length of the rectangular slot is 40 cm.

Embodiment 3

[0018] Embodiment 3: It is basically similar to Embodiment 1, except that: the measuring range of the scale 12 is 65 cm, and the length of the rectangular slot is 50 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com