Punching machine with high vibration resisting capacity

A punching machine and capability technology, applied in the field of punching machines, can solve problems such as difficulty in blanking, device damage, ground damage, etc., and achieve the effects of preventing dangerous accidents, reducing impact force, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

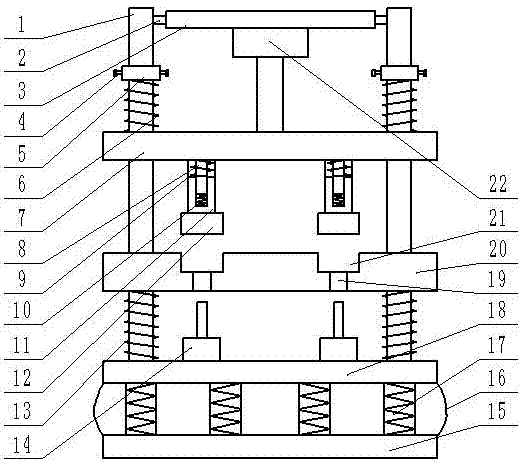

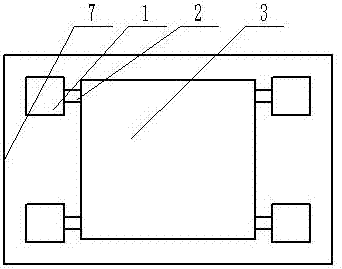

[0017] see Figure 1-2 , a stamping machine with strong shock resistance, comprising a lower base plate 15, an upper base plate 18, a support plate 20, a sliding plate 7 and a column 1, the upper end of the lower base plate 15 is provided with an upper base plate 18, the lower base plate 15 and the upper base plate 18 Airbags 16 are arranged between them, and a plurality of spring columns 17 are arranged in the airbags 16; four uprights 1 are fixedly connected to the four corners of the upper end of the upper bottom plate 18, and the uprights 1 are sequentially provided with supporting plates 20 and sliding plates from bottom to top 7. Between the upper base plate 18 and the support plate 20, a first damping spring 13 is set on the column 1, and a plurality of ejection cylinders 14 are fixedly installed on the upper end of the upper base plate 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com