Plunger type booster pump

A technology of booster pump and plunger type is applied in the field of hydraulic braking of motor vehicles, which can solve the problems of many fault points, reduced booster effect, complicated structure, etc., and achieves the effects of simple structure, easy processing and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

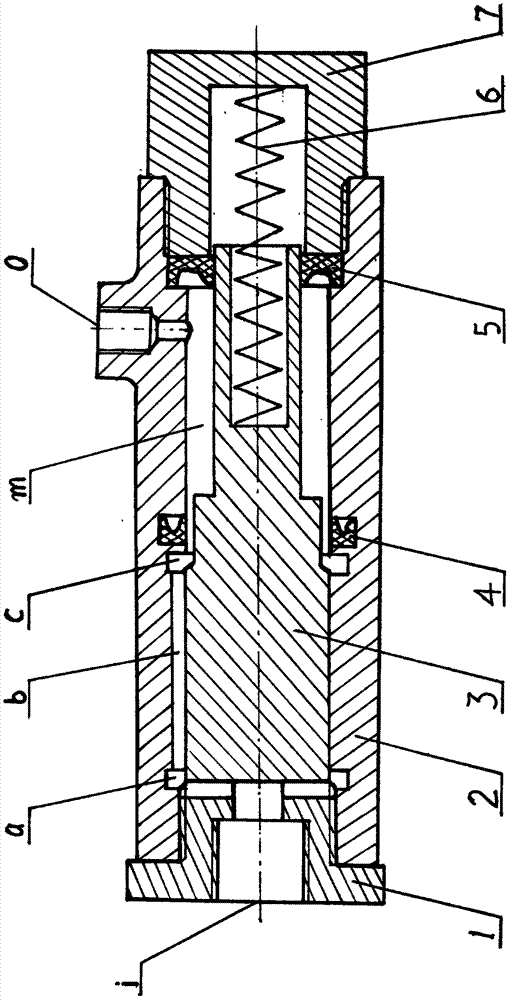

Embodiment 1

[0016] Such as figure 1 As shown, the present invention provides a plunger type booster pump, which includes an oil inlet screw (1), a pump body (2), a different diameter plunger (3), a sealing ring (4), an oil seal (5), a spring ( 6), the spring seat (7), the right end surface of the oil inlet screw (1) is provided with 1-6 grooves, and the bottom of the thread on the left side of the pump body (2) is provided with an annular relief groove (a ), there is an annular oil passage groove (c) on the right side of the annular undercut groove (a), and there are 1-6 axial connecting grooves between the annular undercut groove (a) and the annular oil passage groove (c) (b), the right side of the annular oil passage groove (c) is provided with an annular groove for installing the sealing ring (4), the right side of the annular groove for installing the sealing ring (4) is provided with an oil outlet (o), and the right side is provided with an installation The installation hole of the ...

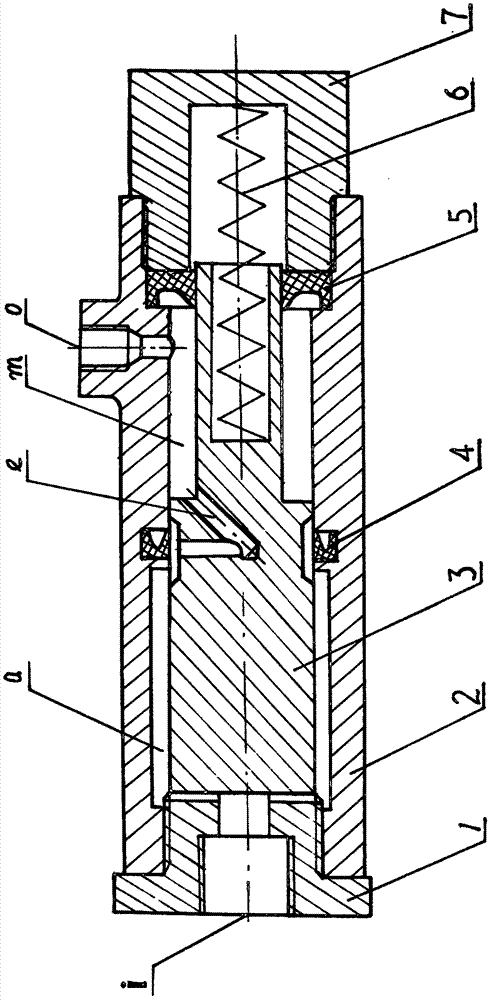

Embodiment 2

[0021] Such as figure 2 As shown, the present invention provides a plunger type booster pump, which includes an oil inlet screw (1), a pump body (2), a different diameter plunger (3), a sealing ring (4), an oil seal (5), a spring ( 6), the spring seat (7), the right end surface of the oil inlet screw (1) is provided with 1-6 grooves, and the bottom of the pump body (2) on the left side of the pump body (2) is provided with an annular On the right side of the undercut groove (a) and the annular undercut groove (a), there is an annular groove for installing the sealing ring (4), and on the right side of the annular groove for installing the sealing ring (4), there is an oil outlet (o), on the right side There is a mounting hole for installing the oil seal (5) and a threaded hole for installing the spring seat (7). The different-diameter plunger (3) is composed of a plunger with a large diameter and a plunger with a small diameter. The right surface of the plunger is provided w...

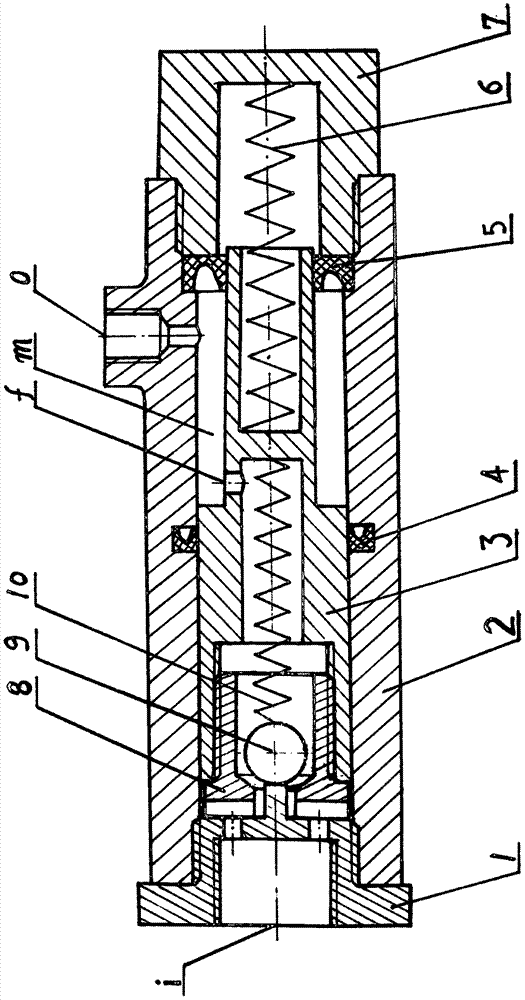

Embodiment 3

[0026] Such as image 3As shown, the present invention provides a plunger type booster pump, which includes an oil inlet screw (1), a pump body (2), a different diameter plunger (3), a sealing ring (4), an oil seal (5), a spring ( 6), spring seat (7), the right side of the threaded bottom hole on the left side of the pump body (2) is provided with an annular groove for installing the sealing ring (4), and the right side of the annular groove for installing the sealing ring (4) is provided with an outlet The oil port (o) and the right side are provided with a mounting hole for installing an oil seal (5) and a threaded hole for installing a spring seat (7). The plug consists of two parts. The left center of the plunger with a large diameter is provided with a check valve seat (8), a check valve steel ball (9), and a check valve spring (10). There are 1-6 small radial holes (f) communicated with the one-way valve on the surface of the small-diameter plunger at the junction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com