Floating positioning and locking mechanism

A locking mechanism and floating positioning technology, applied in the assembly machine, machine container, packaged food, etc., can solve the problem that the spreader and the operator are difficult to accurately control the product direction, the product quality is large, the mounting hole and the fixing frame, and the product whereabouts. Offset and other problems occur to reduce the difficulty of hoisting, improve the stress state of the bolts, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

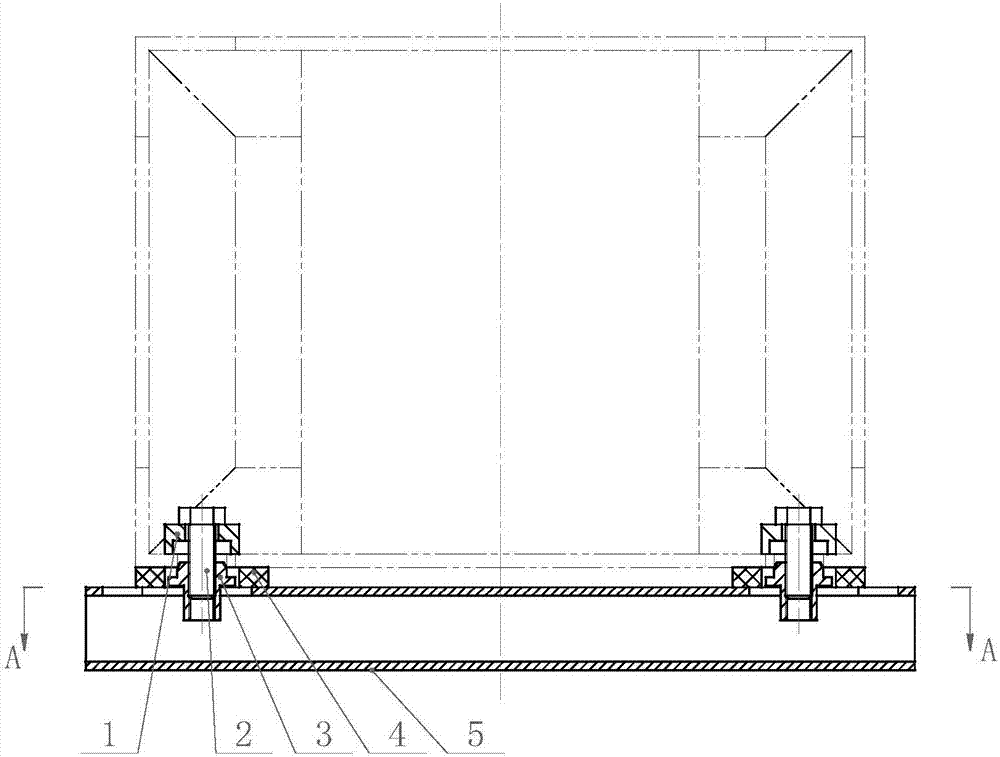

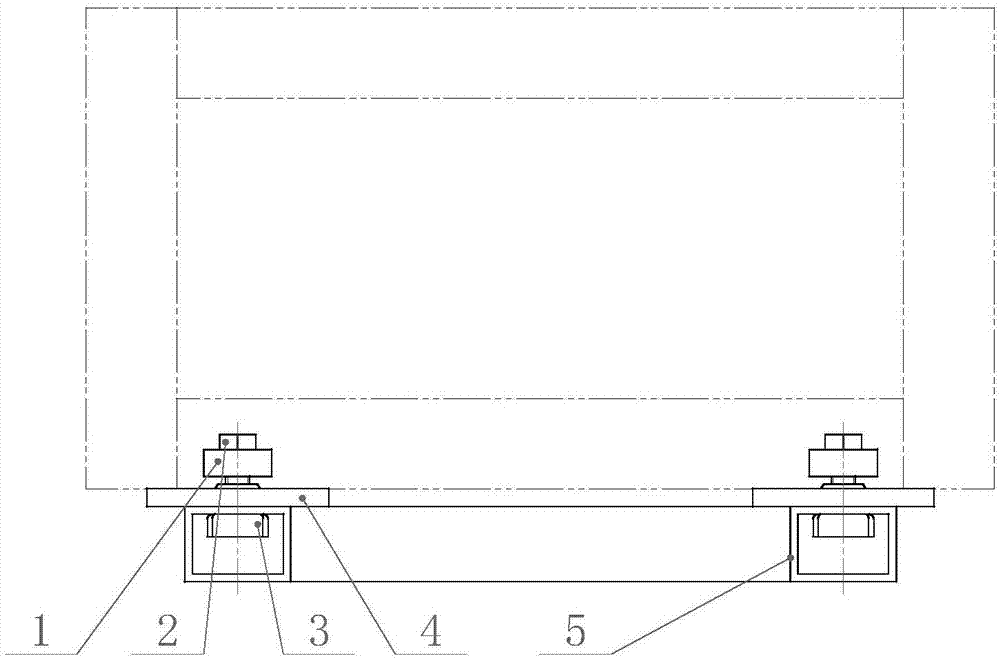

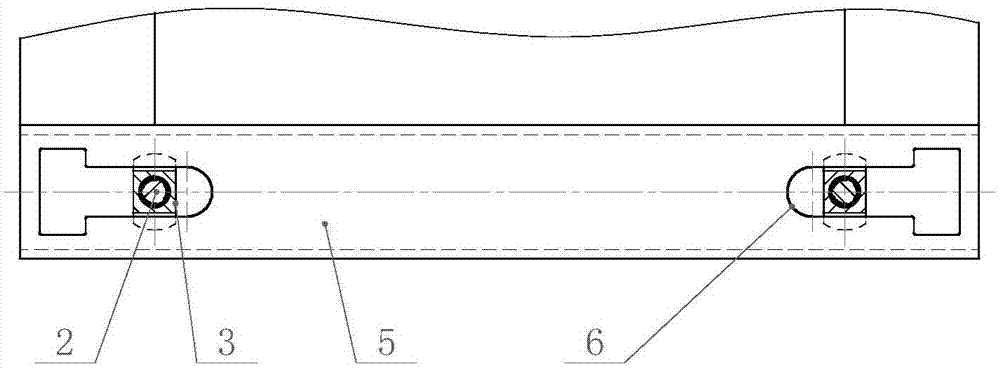

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention includes a washer 1, a bolt 2, a locking block 3, a buffer pad 4, a fixing frame 5, and a guide rod 7. Corresponding to the 4 installation holes of the product, two symmetrical T-shaped slots 6 are provided on the front and back of the fixed frame 5, and a locking block 3 is provided in the T-shaped slot. Such as Figure 5 As shown, the locking block 3 includes a circular boss 8 and a waist circular boss 9, and the circular boss 8 and the waist circular boss 9 are connected by a square connecting part 10; the end surface of the circular boss 8 A threaded hole is provided at the center, and the size of the circular boss 8 is slightly smaller than the mounting hole of the product.

[0028] The bolt 1 is screwed into the inner hole of the locking block 3 . The washer 1 is set on the bolt 2 and is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com