Automatic doffer bobbin clamping device self-adaptive to spindle installation error

A technology of installation error and automatic doffing, applied in textiles and papermaking, etc., can solve the problems of small number of bobbins and large installation error, and achieve the effect of uniform clamping force, small structural modification, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

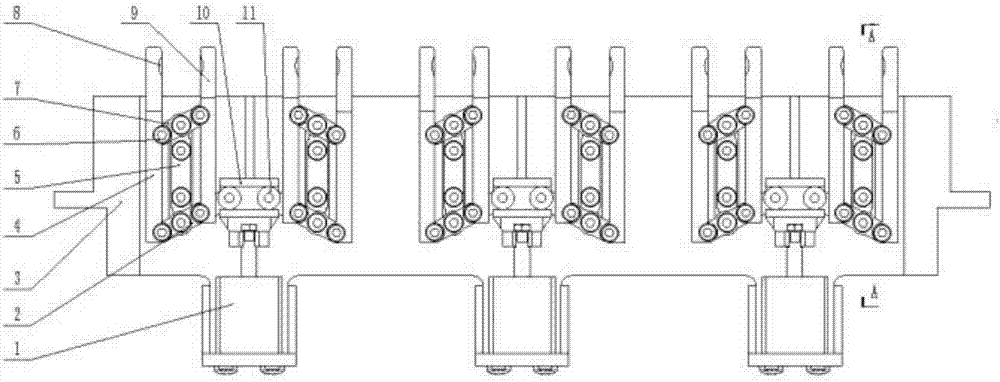

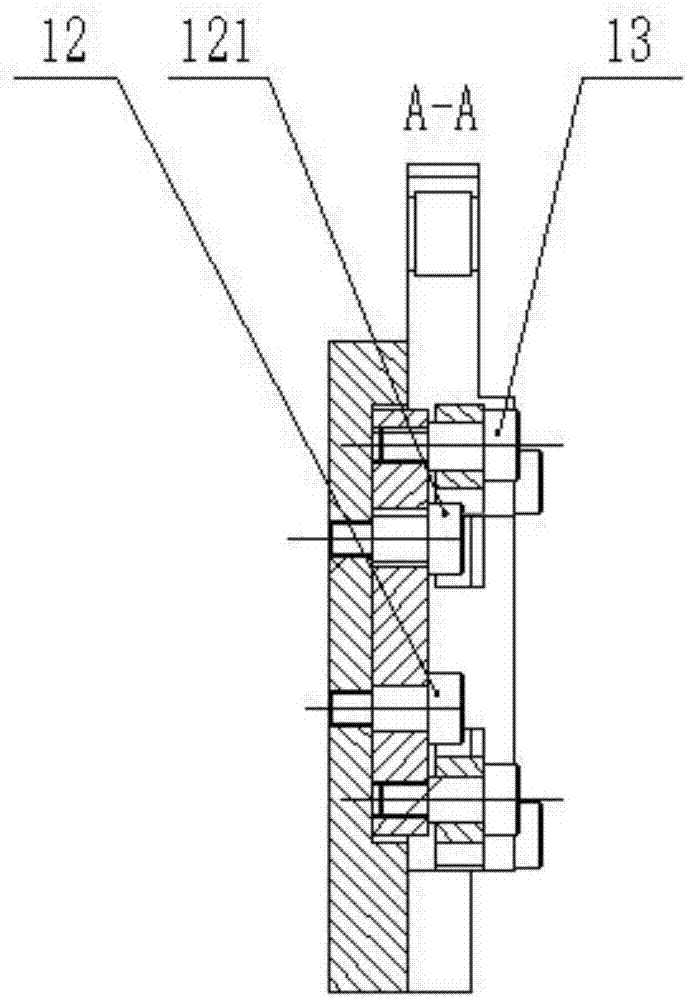

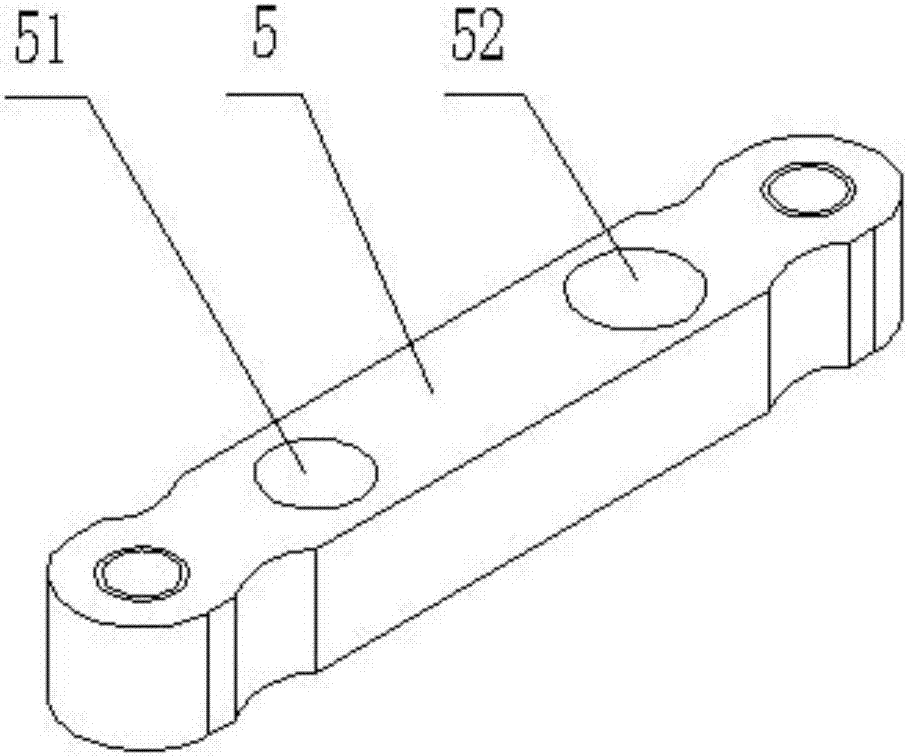

[0023] An automatic doffing bobbin clamping device for self-adaptive spindle installation errors, including a slide plate, a clamping mechanism, a clamping cylinder and a floating connecting plate; two clamping mechanisms form a group, and two parallel clamping fingers The long crank and the short crank are connected by pins to form the rotary pair of the parallelogram mechanism; the clamping cylinder is fixed on the slide plate, and the front end is connected with the high pair of the clamping mechanism through the push plate and roller; the push plate drives the long crank to reciprocate and swing through the roller , to realize the rubbing action of the gripper fingers of the rubbing mechanism; the slide plate is provided with a long groove, and the floating connecting plate is provided with a first hole, and the floating connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com