Process for production of dyed fabric using enzyme aggregates

A technology for enzyme aggregates, fabrics, applied in dyeing, biochemical treatment of enzymes/microorganisms, fabrics, etc., can solve problems such as reducing the mechanical integrity of fabrics, reducing the tensile strength of fabrics and clothing, and difficult to control the degree of fiber removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0098] According to an exemplary embodiment, the first weft yarn of the woven fabric has 118,2tex (5 / 1Ne) to 5,91tex (100 / 1Ne), preferably 19,7tex (30 / 1Ne) to 8,44tex (70 / 1Ne), More preferred is a defined density of 13,13 tex (45 / 1 Ne) to 10,754 tex (55 / 1 Ne); even more preferred, the first weft yarn has a linear density of 11,82 tex (50 / 1 Ne).

[0099] In a preferred embodiment, the linear density of the first weft yarn of the woven fabric ranges from 24,625 tex (24 / 1Ne) to over 11,82 tex (50 / 1Ne), or ranges from 49,25 tex (12 / 1Ne) to 14 , 775tex (40 / 1Ne), or the range is 73,875tex (8 / 1Ne) to 19,7tex (30 / 1Ne), or the range is 118,2tex (5 / 1Ne) to 24,625tex (24 / 1Ne).

[0100] According to an exemplary embodiment, the count or linear density range of the second weft yarn is 118,2tex (5 / 1Ne) to 5,91tex (100 / 1Ne), preferably 19,7tex (30 / 1Ne) to 8,44tex (70 / 1Ne), more preferably 13,13tex (45 / 1Ne) to 10,754tex (55 / 1Ne); even more preferably, the linear density of the second weft y...

Embodiment 1

[0165] Example 1 - Production of Fabric A.

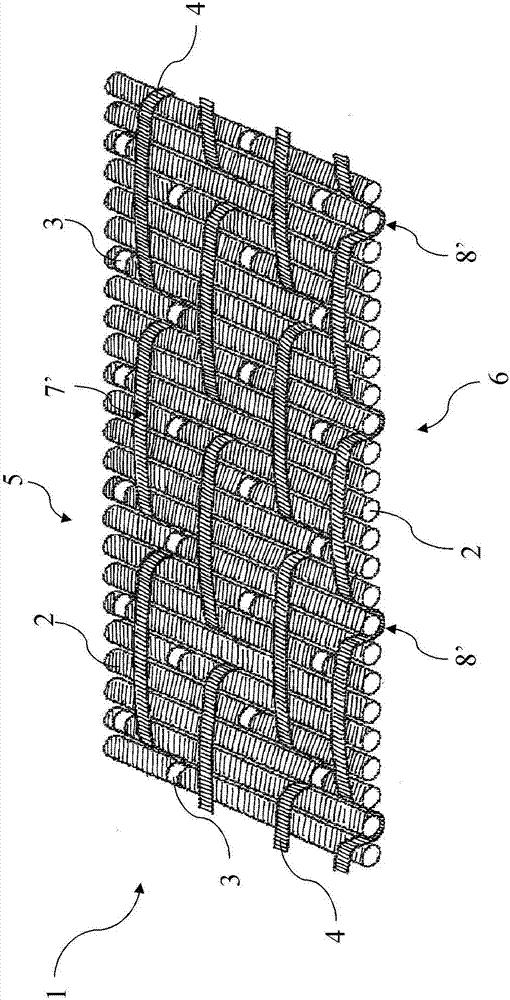

[0166] according to Figure 9 The Weaving Report produces woven fabrics with the following characteristics:

[0167] Warp: 73,875tex (Ne 8 / 1) ring spun slub cotton

[0168] Weft 1: 84,43tex (Ne 7 / 1) ring spun cotton

[0169] Weft 2: 11, 82tex (Ne 50 / 1) combed cotton

[0170] Warp density: 29.5 threads / cm

[0171] Weft density: 42.0 picks / cm

Embodiment 2

[0173] Comparative Example 2 - Treatment with Pumice

[0174] A sample of the fabric of Example 1, measuring 30 cm x 20 cm, was subjected to the following stone:liquor ratio: 1:10, 150 g of pumice for 1 kg of fabric, at 30° C. for 15 minutes. The results are shown in Figure 8 The sample 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com