Obstruction block for triple-wave form beam guardrail

A technology of anti-blocking blocks and guardrails, which is applied to roads, road safety devices, roads, etc., can solve the problems of adverse effects on bolt installation quality, inconvenient bolt installation and tightening, and high labor intensity, so as to facilitate mechanized operations and process operations , reduce the amount of labor, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

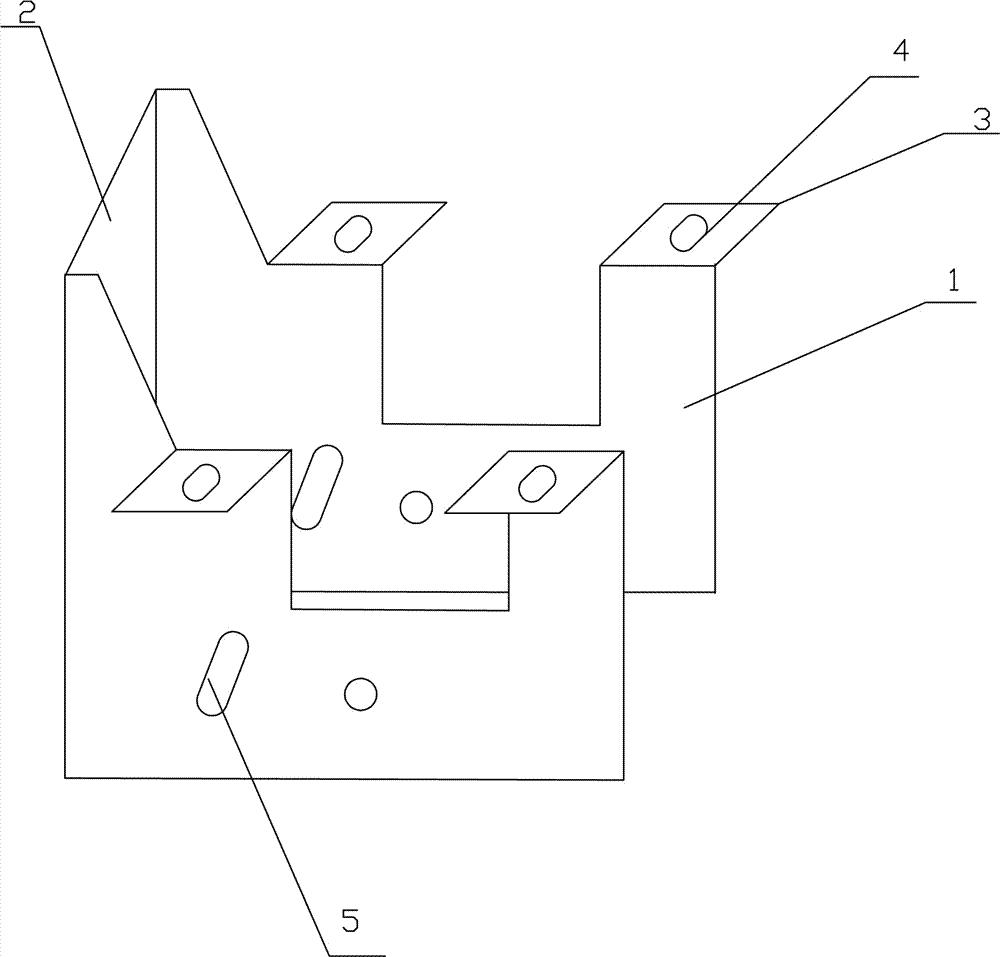

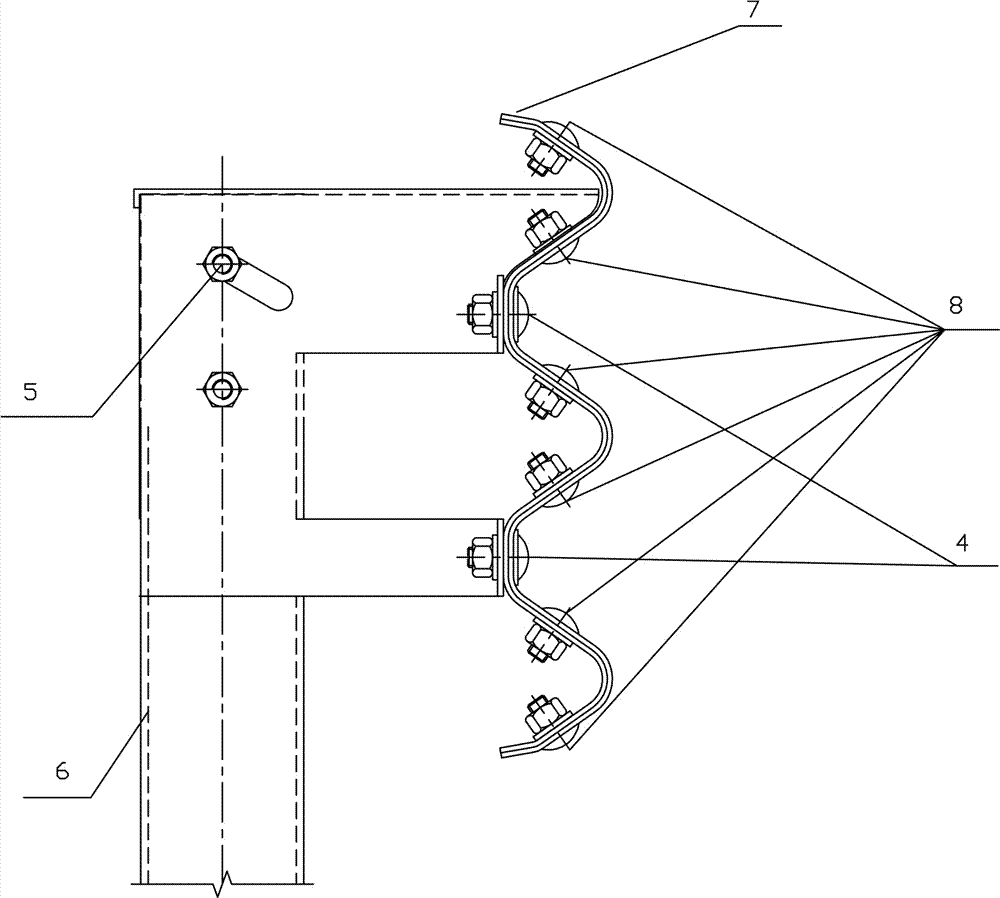

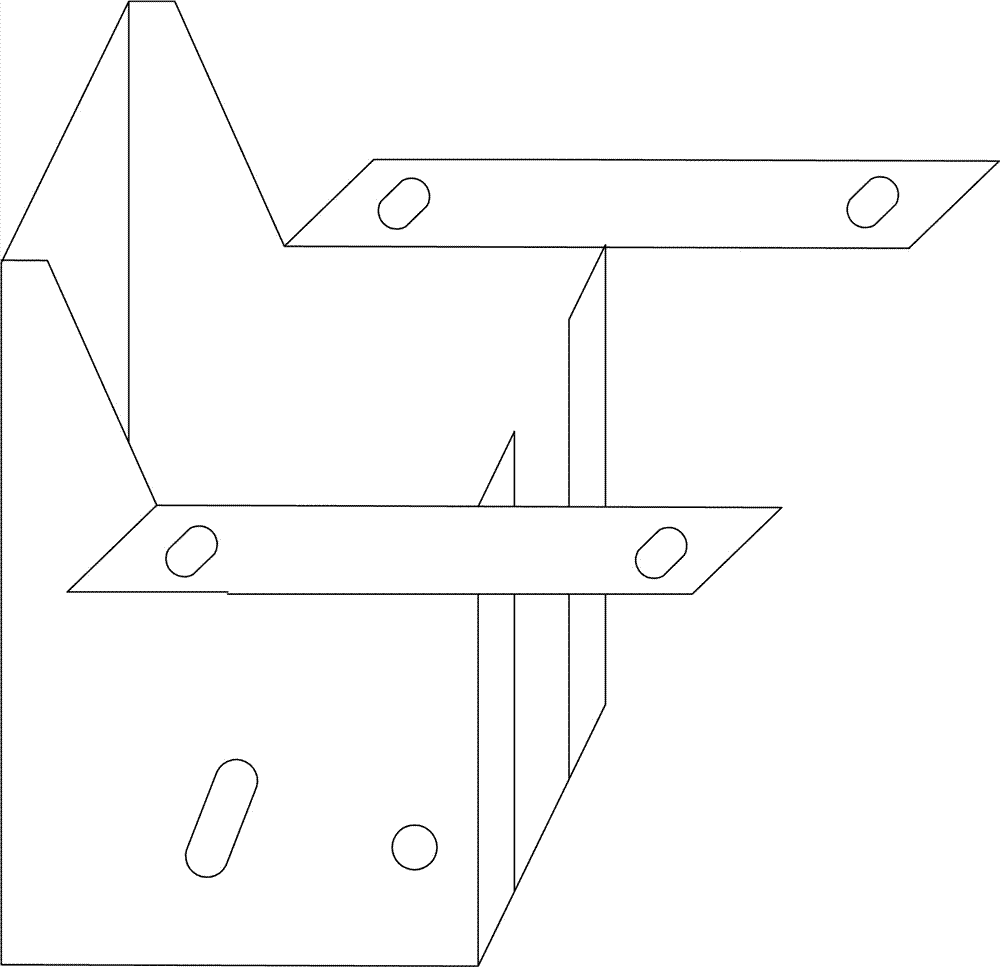

[0019] Such as figure 1 As shown, a three-wave beam guardrail anti-resistance block, the anti-resistance block is installed on a column 6 and includes two column connecting plates 1, a resisting plate 2 and four corrugated beam connecting plates 3 for connecting corrugated beams 7 ,

[0020] The abutment plate 2 is symmetrically installed at both ends of the two column connecting plates 1;

[0021] A concave groove is formed on the side of the two vertical column connecting plates 1 away from the vertical column 6, and the bottom of the concave groove is close to the vertical column 6;

[0022] The four corrugated beam connecting plates 3 are arranged symmetrically, a single corrugated beam connecting plate 3 is installed on the top side of the concave groove, and the corrugated beam connecting plate 3 is provided with a first connecting hole 4,

[0023] The column connecting plate 1 is provided with at least two column connecting holes 5.

[0024] The abutment plate 2 has a square sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com