Automatic mop washing mopping machine

A technology of automatic cleaning and hand mopping, applied in the direction of road cleaning, cleaning methods, cleaning methods and utensils, etc., can solve problems such as trouble, inability to continuously mop the floor, and untimely removal and cleaning, so as to improve the cleaning effect and save water Obvious effect, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

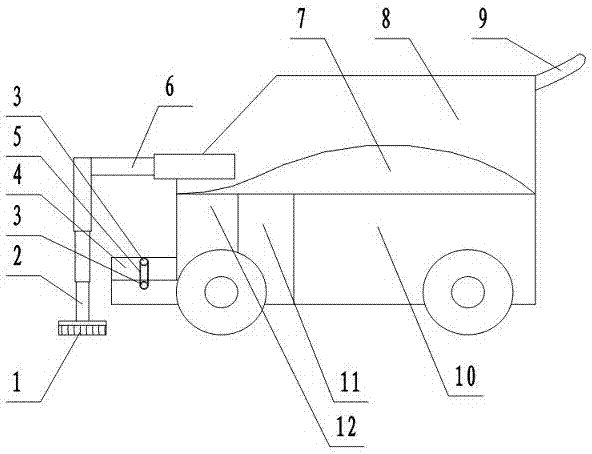

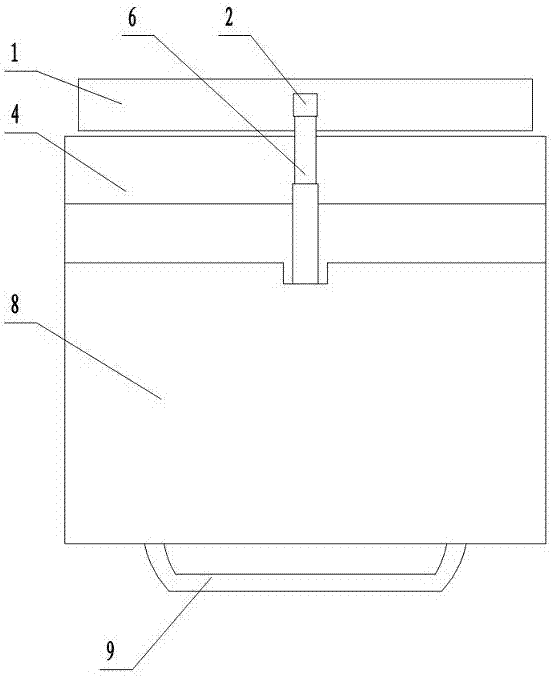

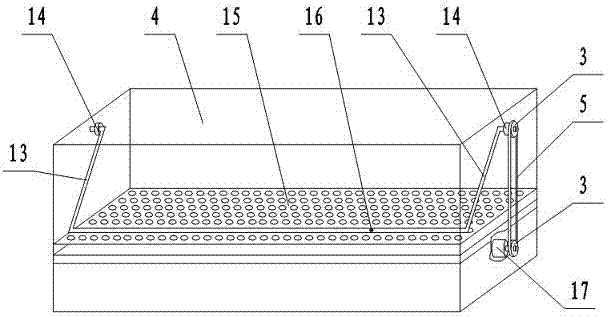

[0012] figure 1 In, is a side view of an automatic cleaning mopping machine. figure 2 in, yes figure 1 top view. combine figure 1 , figure 2 Narrate together. Car body 8 front upper part is equipped with boom 6. The front end of the boom 6 is vertically connected with the upper end of the lifting rod 2 . The lower end of the lifting rod 2 is connected in the middle of the flat plate above the handkerchief 1. figure 1 The mopping seen in is the width direction of the two ends of the mopping. Both the boom and the lifting rod are square telescopic tubes. Hydraulic cylinders are installed in the pipe frame of the jib frame and the lifting rod. The lifting rod can be stretched up and down, driving the mop to move up and down. The boom can be stretched back and forth, driving the handle to move back and forth. Clear water tank 7, secondary sewage tank 12, light sewage tank 11 and sewage tank 10 are arranged in the car body. Cleaning pool 4 is installed in car body 8 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com