Assembling method for starting motor with built-in electromagnetic switch

A starter motor and electromagnetic switch technology, which is applied in the direction of starting motors for engines, starting devices with mechanical power storage, engine components, etc., and can solve the problems of coil assembly damage, connection reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

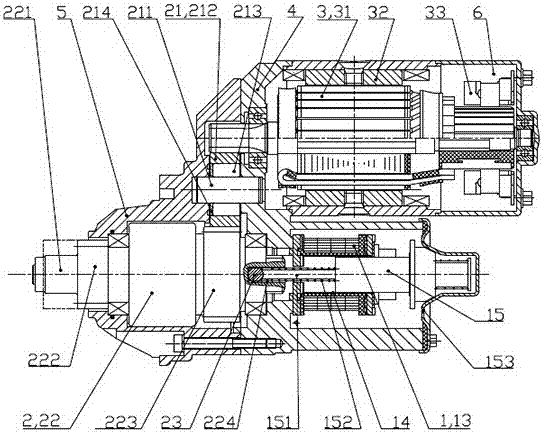

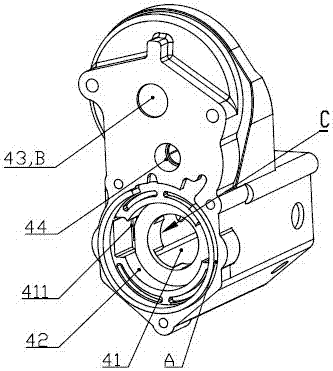

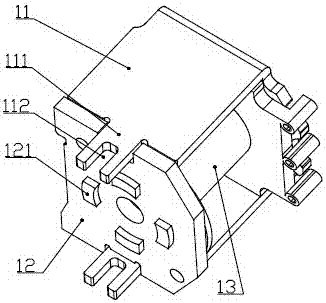

[0021] Below by specific embodiment, in conjunction with accompanying drawing, the technical solution of the present invention is described in further detail:

[0022] see figure 1 , figure 2 and image 3 , an assembly method of a starter motor with a built-in electromagnetic switch, the starter motor in the assembly method includes a starter motor housing 4, a starter motor front cover 5, a starter motor rear cover 6, a motor assembly 3, an electromagnetic switch assembly 1 and a transmission component2. The motor assembly includes an armature assembly 31 , a stator assembly 32 and a carbon brush holder assembly 33 . The transmission assembly 2 includes a transition gear assembly 21 and a one-way device assembly 22 meshing with the gear shaft at the output end of the motor assembly 3 . The one-way device assembly 22 includes a drive shaft 221 , a drive gear 222 and a transmission gear 223 . A driving hole 224 is defined at a rear end of the driving shaft 221 . The elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com