A support system for a high-rise fabricated steel structure frame and its construction method

A steel structure frame and support system technology, applied in the direction of building components, building structures, protected buildings/shelters, etc., can solve the problems of window opening and wall panel assembly, steel support prone to instability, and large residual deformation and other problems to achieve the effect of improving construction efficiency, avoiding connection and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

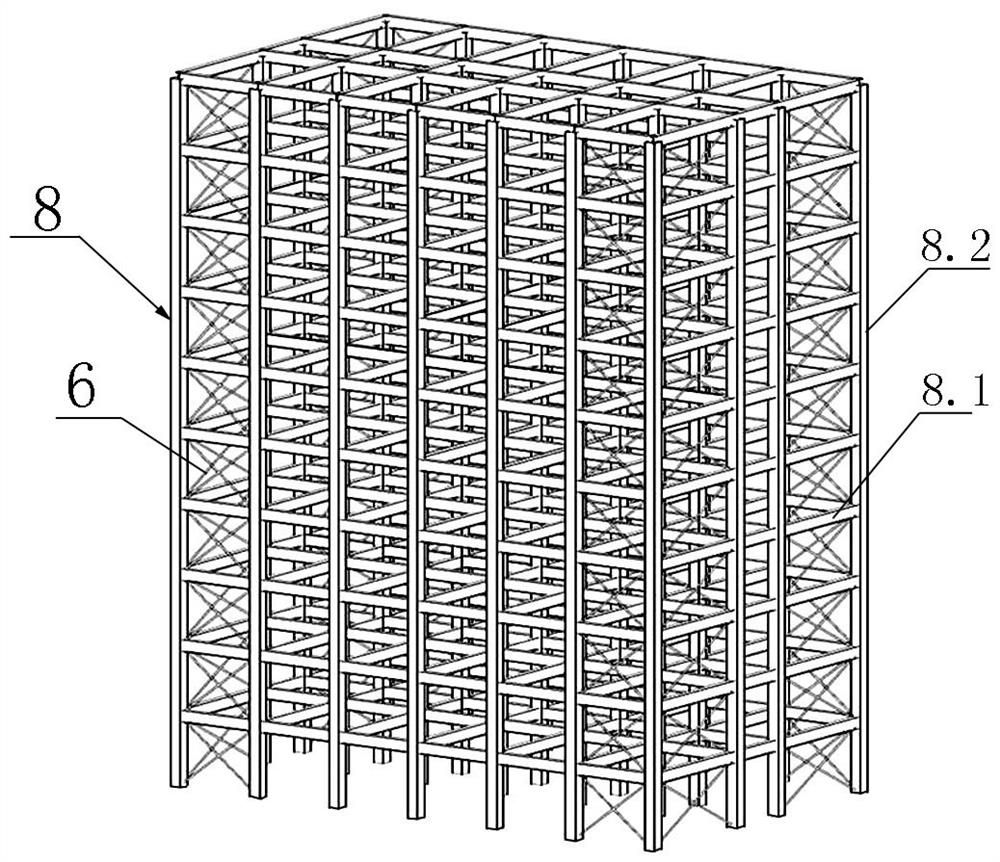

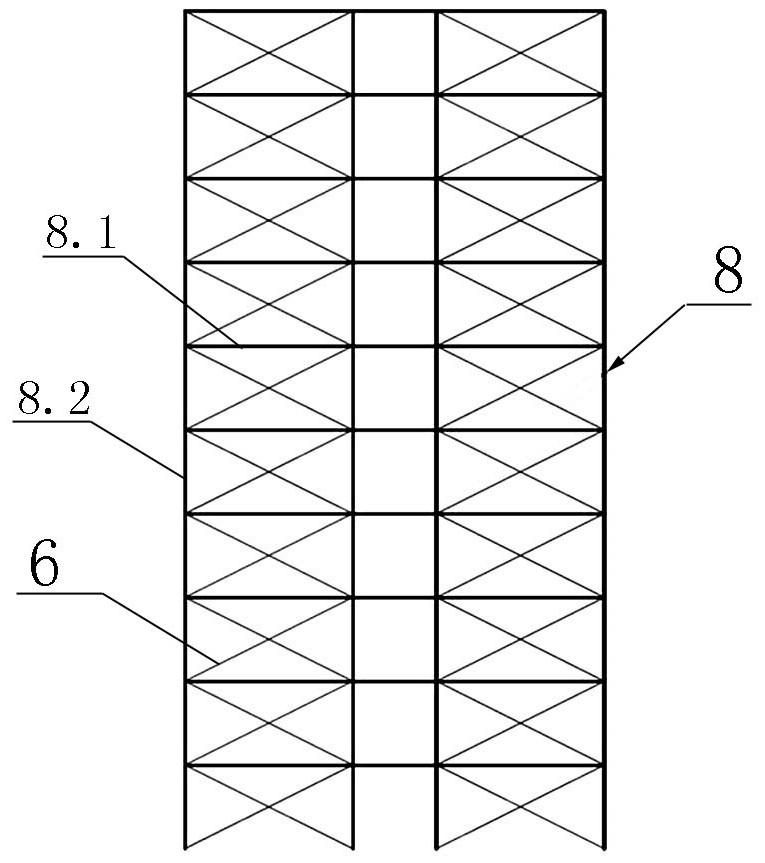

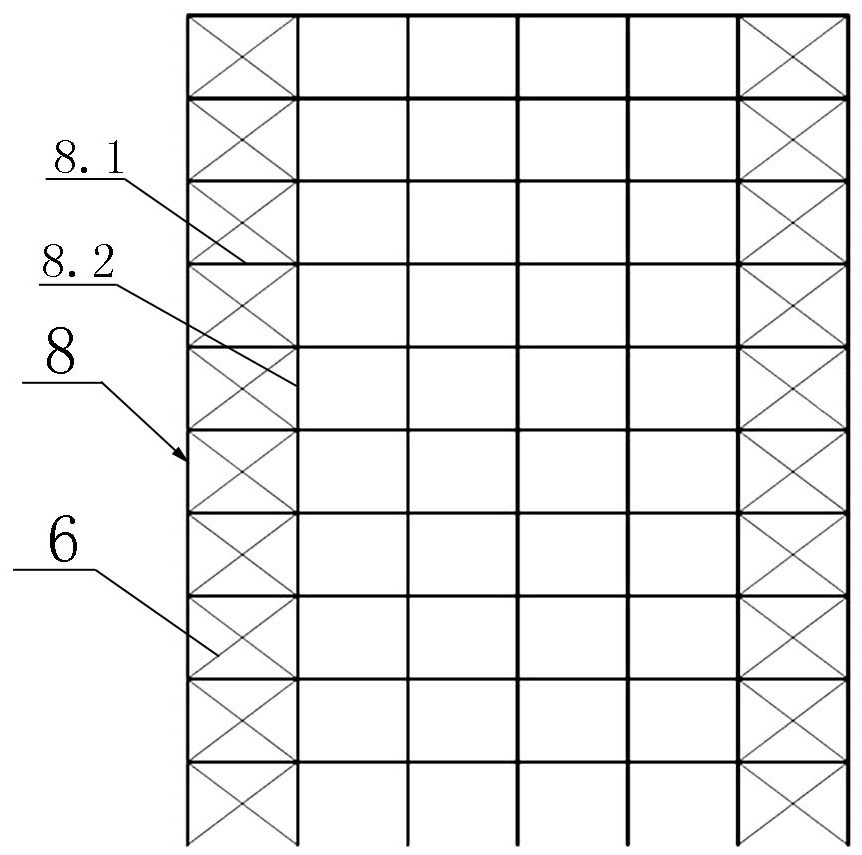

[0038] The support system in this embodiment is suitable for high-rise residential buildings with a height of about 100m. Its main structure is a prefabricated steel frame structure. In order to increase the horizontal rigidity of the overall structure and improve the economic benefits of the prefabricated steel structure, it is arranged at corresponding positions on the same floor or across floors. Support system, while avoiding the impact of the support system on the window opening and assembly of wall panels. The support in the support system adopts high-strength cables 6, and a compression spring 2 with an energy dissipation damper 1 is set at the connection position with the steel structure frame 8, and the steel rod 3 passes through the compression spring 2 and is connected to the end of the anchor plate 4 Tighten the nut 11, one end of the high-strength cable 6 is hingedly connected to the lower steel rod 3, and the other end is also hingedly connected to the upper steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com