Visual detection method of rivets

A visual inspection and rivet technology, applied in the field of visual inspection of rivets, can solve problems such as complex processes, and achieve the effect of high tolerance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

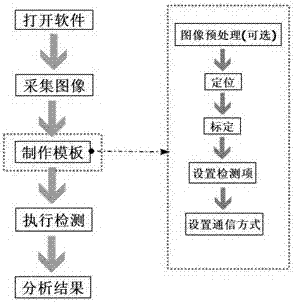

Method used

Image

Examples

Embodiment 1

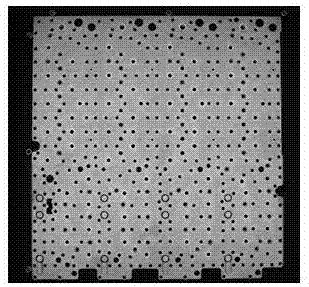

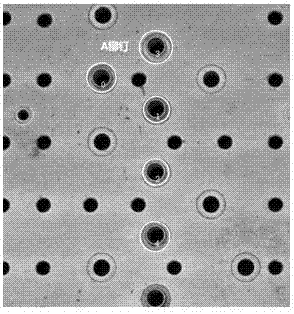

[0037] refer to Figure 2~Figure 4 , figure 2 For the full-page rivet image, the rivet visual detection method provided by the present invention is used for visual detection, and the obtained image 3 , Figure 4 result. in, image 3 Using the matching score, contrast, etc. as parameters, using methods such as edge contour extraction, shadow area, etc., to obtain the visual detection results of A rivets, the white circle in the figure is the position of A rivets detected by this rivet visual detection method; Figure 4 Using the matching score and contrast as parameters, using methods such as contour comparison and auxiliary masking, the visual detection results of B rivets and the absence of rivets are obtained. The white circle in the figure is the B rivet position detected by this rivet visual detection method, and the black circle is The rivet missing position detected by the rivet visual inspection method.

[0038] The above experimental results show that the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com