Chip packaging apparatus of multi-core intelligent card

A chip packaging and smart card technology, applied in transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of large chip tape punching mechanism, longer production and assembly cycle, and increased maintenance costs, etc., to achieve easy programming control , The effect of shortening the handling time and shortening the production and assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

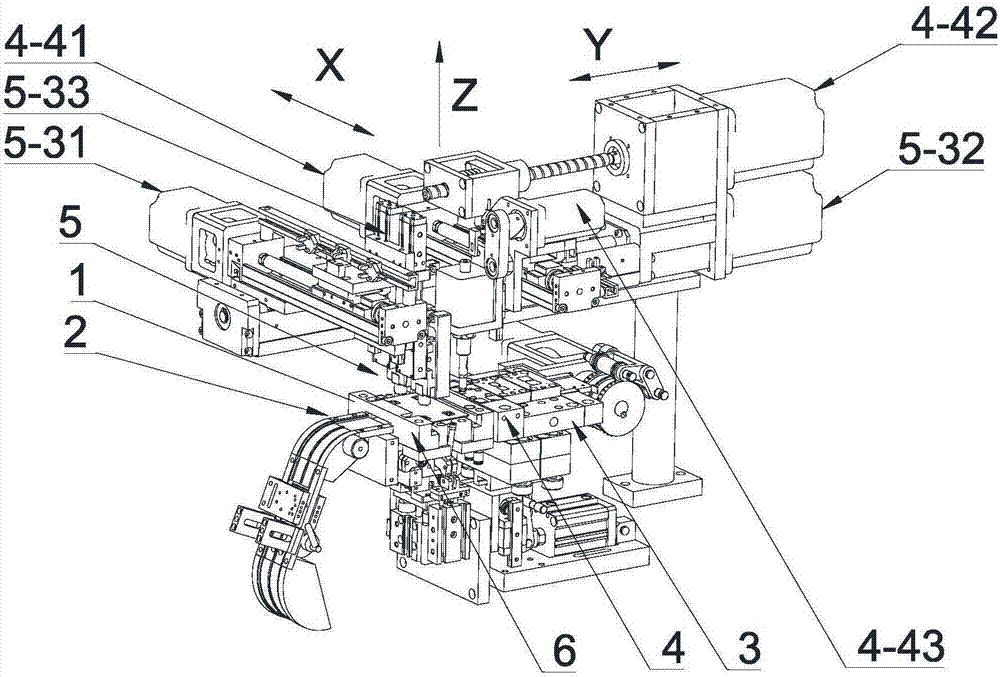

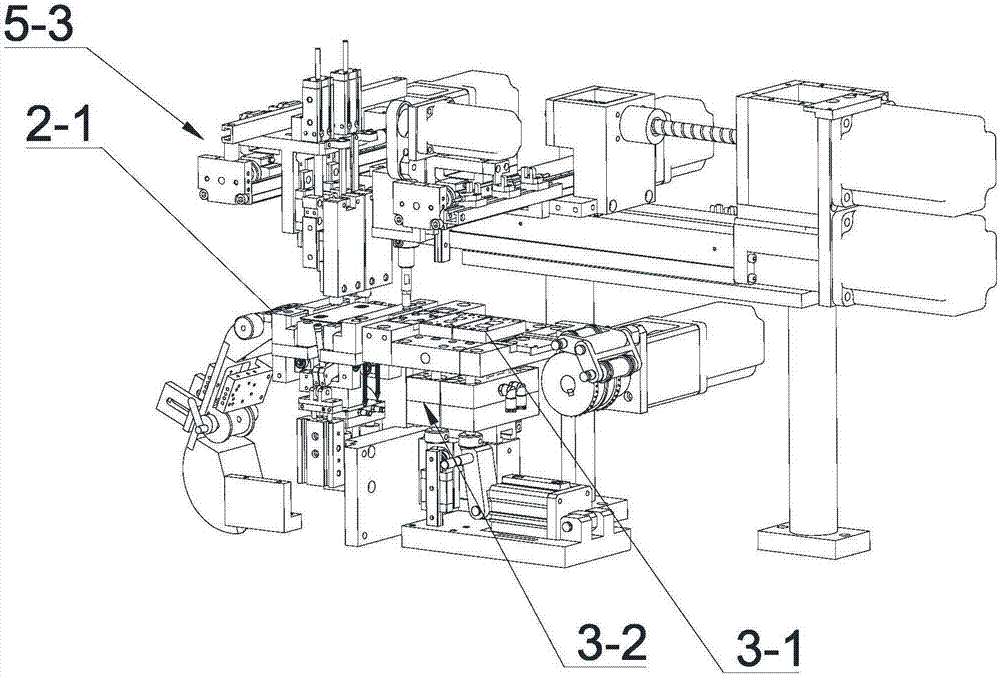

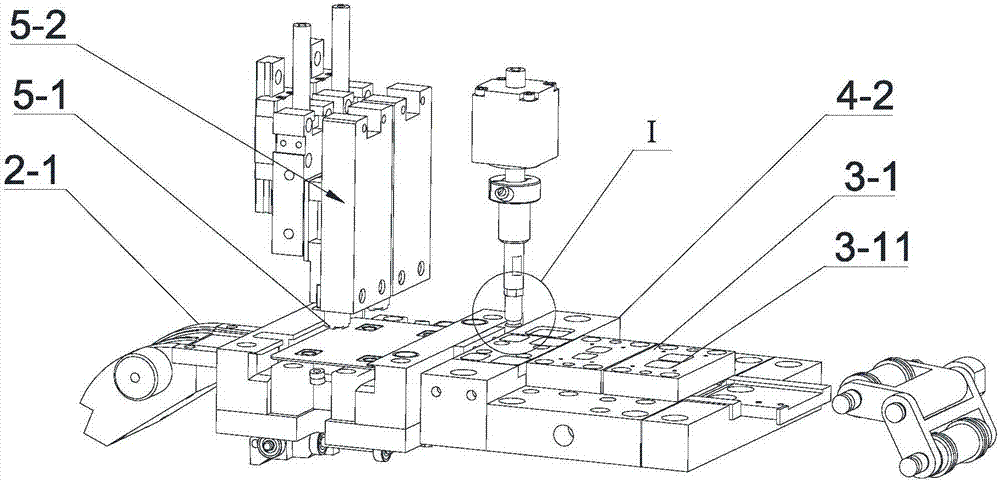

[0039] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0040] see Figure 9 , in the smart card production process, it is necessary to package chips into the card 7 . A common smart card is provided with a chip in each card 7. In addition, some cards 7 are provided with multiple chips, such as two chips, four chips, etc., and the chips in these multi-chip cards 7 are divided into two parts and arranged on the card. At both ends of 7, the orientations of the chips at different ends are opposite (one of the four corners of the chip is provided with a hypotenuse, the position of the hypotenuse is different, and the orientation of the chip is different), while the orientation of the chips located at the same end is unanimous. The chips at one end of the card 7 are called the first group of chips 7-1, and the chips at the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com