Large-scale deployable reflective surface based on centrally deformed truss with external winding ribs

A reflective surface and truss technology, applied to antennas, electrical components, etc., can solve the problems of low deployment reliability, large deployment area, and small folded volume, and achieve the effect of strong deployment reliability, large unfolded area, and small folded volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

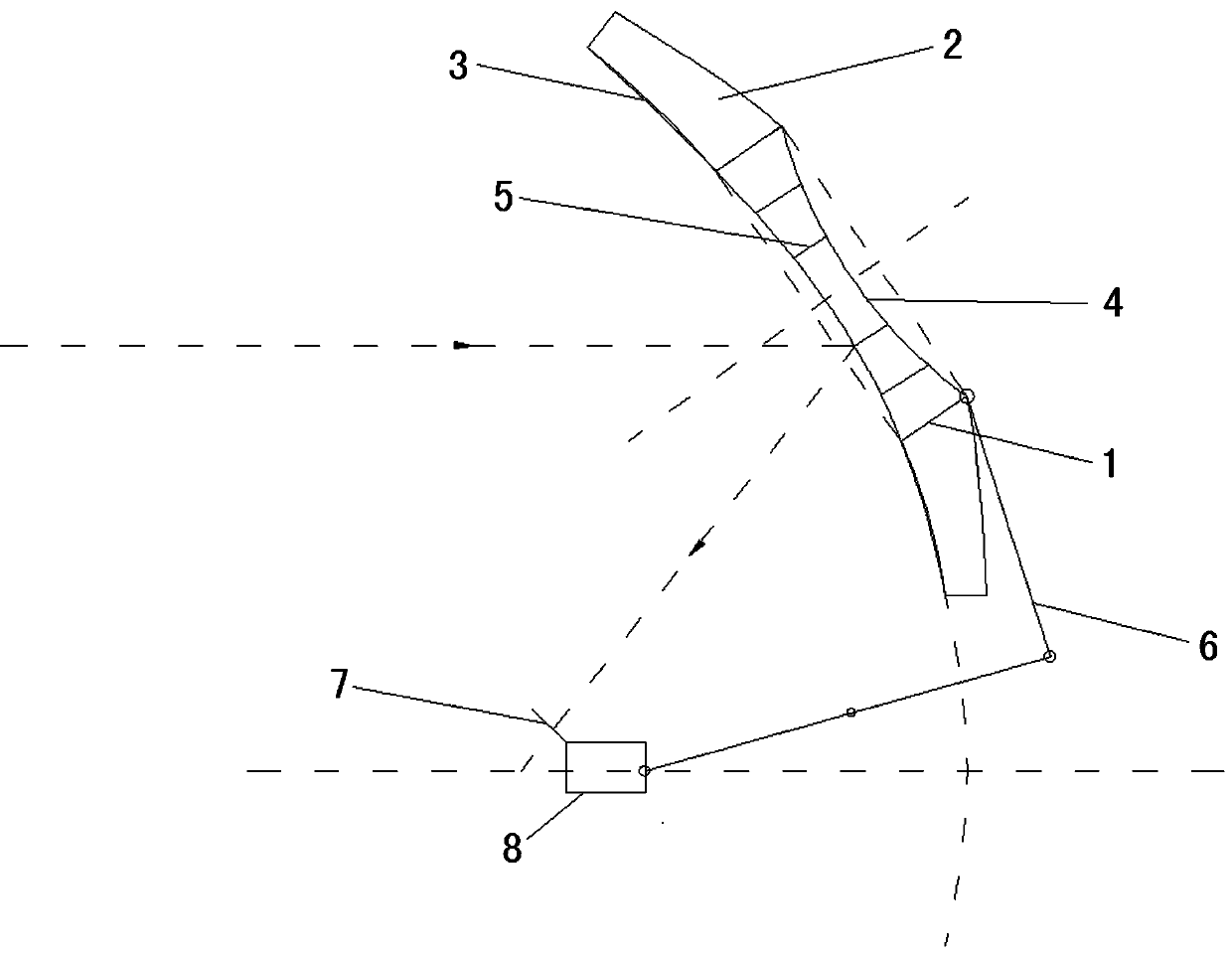

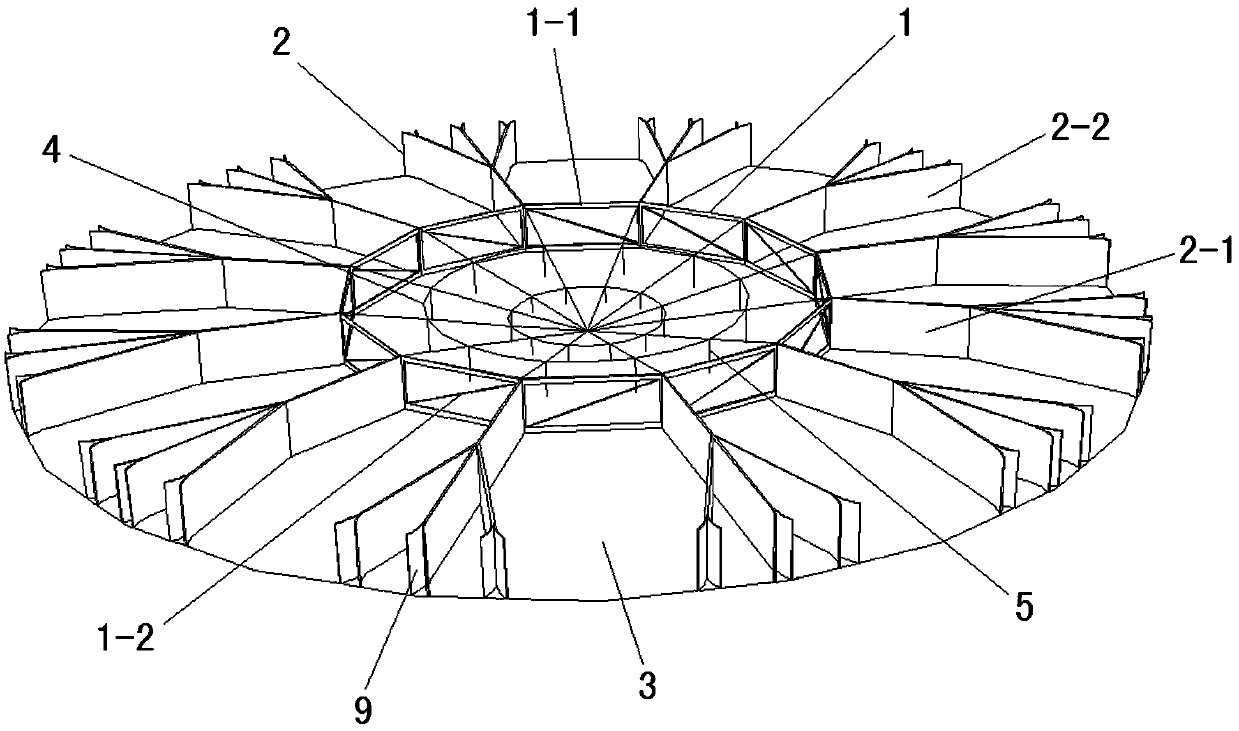

[0011] Specific implementation mode one: as Figure 1~Figure 4 As shown, the present invention discloses a large-scale expandable reflective surface based on a centrally deformed truss with external winding ribs, including a centrally deformed truss 1, a reflective surface 3, a tensioned back net 4, a support arm 6, a feed source 7, and multiple bifurcated ribs 2 and a plurality of shape-controlling adjustment cables 5, the central deformation truss 1 is a regular polygonal truss composed of an even number of rectangular frame units 1-1 sharing short sides, and the plurality of bifurcated ribs 2 are all symmetrical bifurcations The variable cross-section thin plate, the front edge of each of the bifurcated ribs 2 and the central deformation truss 1 corresponding to the rectangular frame unit 1-1 short side columns are connected by hinges, and the reflective surface 3 is a geometric deflection paraboloid, The central area of the back of the reflective surface 3 is connected t...

specific Embodiment approach 2

[0012] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment 1. The central deformation truss 1 is composed of a plurality of vertical rectangular frame units 1-1 sharing short side columns to form a regular polygonal prism, and each of the The two long sides of the rectangular frame unit 1-1 are horizontally arranged elongated sheets, and the two short sides of each rectangular frame unit 1-1 are vertically arranged cylinders, and each rectangular frame unit 1 The four corners of -1 are fixed with torsion springs, and each rectangular frame unit 1-1 is fixed with elongated thin strips 1-2 at one diagonal. The central deformation truss 1 can be folded in the center through the first centripetal folding. The two long rods of each rectangular frame unit 1-1 are in the shape of long strips. One diagonal line of each rectangular frame unit 1-1 There are long thin laths 1-2 for stabilizing the rectangular frame uni...

specific Embodiment approach 3

[0013] Specific implementation mode three: as figure 2 As shown, this embodiment is a further description of Embodiment 1. Each of the bifurcated ribs 2 includes a main rib 2-1 and two symmetrically bifurcated secondary ribs 2-2. The two sides of the central position of the main rib 2-1 are respectively connected with the front plate edge of a secondary rib 2-2 through leaf springs to form an acute angle integrated fiber connection. The leaf spring can expand the bifurcated secondary ribs 2-2 to a specified angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com